A kind of water-based texture wall film paint and preparation method thereof

A texture and wall film technology, applied in the field of water-based texture wall film coatings and their preparation, can solve the problems of increasing the workload of the coating process, moldy walls, and poor durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A water-based texture wall film coating, comprising component A and component B, the weight ratio of component A and component B is 3:5;

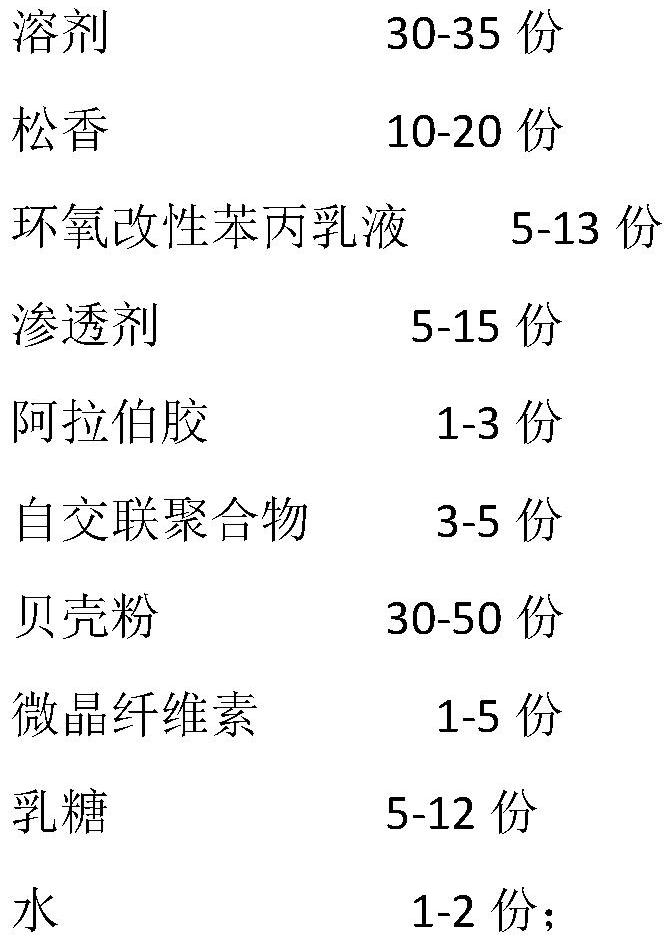

[0044] Wherein component A comprises each material of following weight portion:

[0045]

[0046] Component B comprises each material of following parts by weight:

[0047]

[0048]

[0049] Wherein, the solvent is ethanol.

[0050] Preferably, the fineness of the shell powder is 12000 mesh.

[0051] Preferably, the fineness of the transparent powder is 12500 mesh.

[0052] Preferably, the epoxy equivalent of the epoxy resin is 0.25.

[0053] Its construction method includes the following steps:

[0054] Step 1, prepare component A, spray a layer of water on the wall to be constructed to ensure that the wall to be constructed is semi-wet; the effect of water is to promote the rapid penetration of some components in component A into the wall substrate; and soften The original coating layer is convenient for the components ...

Embodiment 2

[0068] A water-based texture wall film coating, comprising component A and component B, the weight ratio of component A and component B is 7:2;

[0069] Wherein component A comprises each material of following weight portion:

[0070]

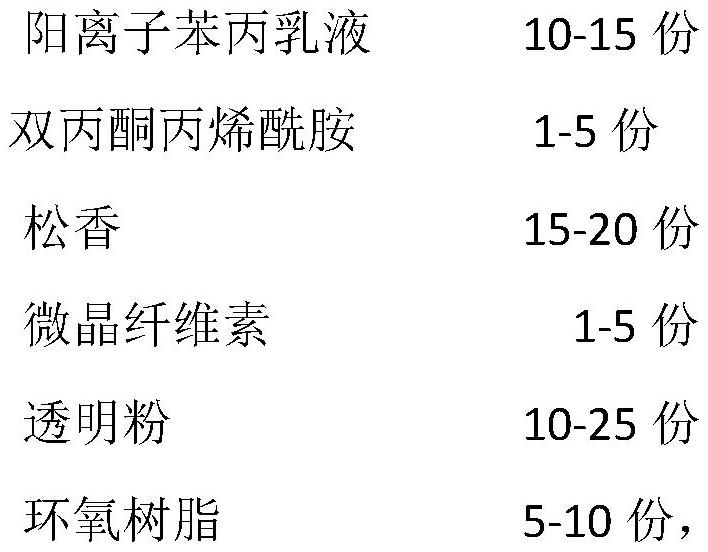

[0071] Component B comprises each material of following parts by weight:

[0072]

[0073] Wherein, the solvent is ethanol, methanol, acetone, acetic acid or oxalic acid.

[0074] Preferably, the fineness of the shell powder is 12000 mesh.

[0075] Preferably, the fineness of the transparent powder is 12500 mesh.

[0076] Preferably, the epoxy equivalent of the epoxy resin is 0.25.

[0077] Its construction method includes the following steps:

[0078] Step 1, prepare component A, and spray a layer of water on the wall to be constructed to ensure that the wall to be constructed is semi-wet;

[0079] Step 2: Brush component A directly on the wall with construction, and control the thickness of the coating so that component A can compl...

Embodiment 3

[0093] A water-based texture wall film coating, comprising component A and component B, the weight ratio of component A and component B is 3:5;

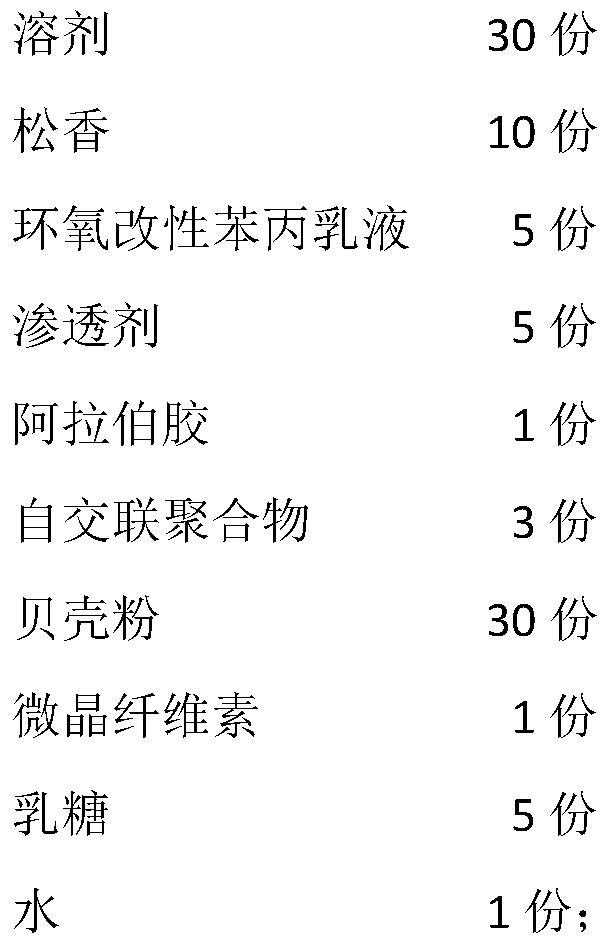

[0094] Wherein component A comprises each material of following weight portion:

[0095]

[0096] Component B comprises each material of following parts by weight:

[0097]

[0098] Wherein, the solvent is ethanol, methanol, acetone, acetic acid or oxalic acid.

[0099] Preferably, the fineness of the shell powder is 12000 mesh.

[0100] Preferably, the fineness of the transparent powder is 12500 mesh.

[0101] Preferably, the epoxy equivalent of the epoxy resin is 0.25.

[0102] Its construction method includes the following steps:

[0103] Step 1, prepare component A, and spray a layer of water on the wall to be constructed to ensure that the wall to be constructed is semi-wet;

[0104] Step 2: Brush component A directly on the wall with construction, and control the thickness of the coating so that component A can compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com