Method for aluminum electrolysis cell waste cathode stripping treatment and fluoride recovery

A technology of aluminum electrolytic cell waste and recycling method, which is applied in the field of aluminum electrolytic cell dismantling and waste cathode treatment and comprehensive utilization, and can solve the problems of unsatisfactory pre-dissolution effect of soluble fluorine, difficulty in solid-liquid separation, and large amount of water for dissolution. Achieve the effect of comprehensive utilization of non-discharge resources, simple and easy method, and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 : Waste cathode treatment and utilization of electrolytic aluminum production enterprises with an annual output of 200,000 tons of aluminum

[0035] (1) Basic information:

[0036] The electrolytic aluminum plant with an annual production capacity of 200,000 tons adopts 300kA large-scale prebaked tank electrolysis technology and prebaked anode roasting technology. The annual output of waste cathodes is 8,000 tons. In the past, safe landfill was used, but now it is treated by sorting, but the sorting effect is not good, and the wastewater is difficult to treat.

[0037] (2) Application method

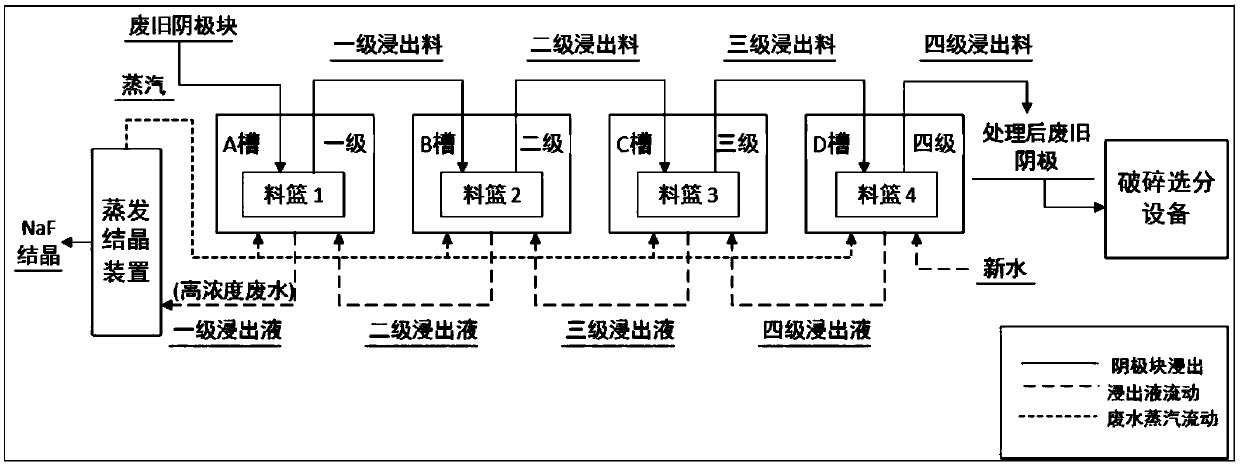

[0038] According to the technology proposed by the present invention (see figure 1 ), set up four dissolution tanks (numbers A, B, C, D), and carry out four-stage dissolution treatment in sequence. That is to say, the waste cathode block is put into tank A first for primary dissolution; after the specified time, water control is proposed, and then it enters tank B ...

Embodiment 2

[0045] Example 2 : Application in waste cathode treatment of electrolytic aluminum enterprises with an annual output of 600,000 tons

[0046] (1) Basic information

[0047] The electrolytic aluminum plant with an annual production capacity of 600,000 tons adopts 300kA large-scale prebaked tank electrolysis technology and prebaked anode roasting technology. The annual output of waste cathodes is 20,000-24,000 tons. The flotation process is proposed to be used for treatment, and the first step is to realize the dissolution and harmless disposal of soluble fluorine and cyanide.

[0048] (2) Application method

[0049] According to the technology proposed by the present invention (see figure 1 ), in order to ensure the dissolution effect, five dissolution tanks (numbers A, B, C, D, E) are set up, and the five-stage dissolution treatment is carried out in sequence, and the operation mode is the same as that of the four-stage. That is to say, the waste cathode block is put int...

Embodiment 3

[0056] Example 3 : Application in centralized treatment of waste cathodes in industrial parks with an annual output of 1 million tons of electrolytic aluminum

[0057] (1) Basic information

[0058] Aluminum Industrial Park, with an annual electrolytic aluminum production capacity of 1 million tons. Adopt 200 ~ 350kA large pre-baked tank electrolysis technology and pre-baked anode roasting technology. The annual output of waste cathodes is 38,000-46,000 tons. The waste cathode adopts leaching treatment + flotation, the solid product is separated and comprehensively utilized, and the waste water is evaporated and crystallized.

[0059] (2) Application method

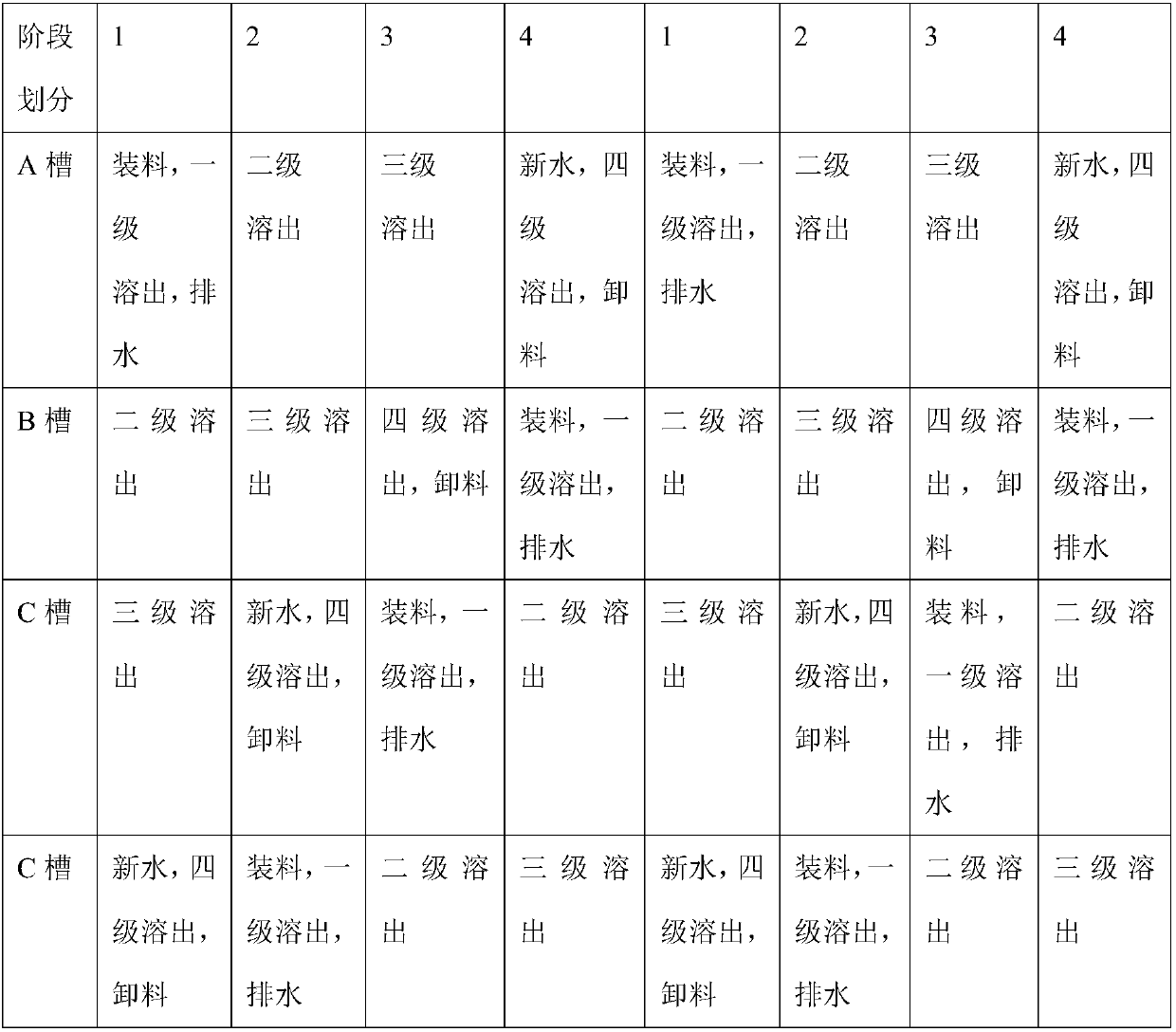

[0060] According to the process proposed by the present invention, four stripping tanks (numbered A, B, C, D) are set, and four-stage stripping treatments are carried out successively. In the operation design, the method of "adjusting tanks but not water" is adopted, that is, each leaching tank performs four-stage l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com