Aluminum alloy precise casting solidification defect control method

A precision casting and control method technology, applied in the field of aluminum alloy casting, can solve problems such as difficult processing and no solution, and achieve the effects of increasing solidification speed, suppressing loose defects, and increasing cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

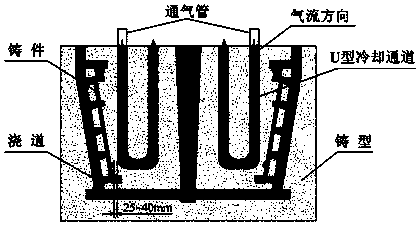

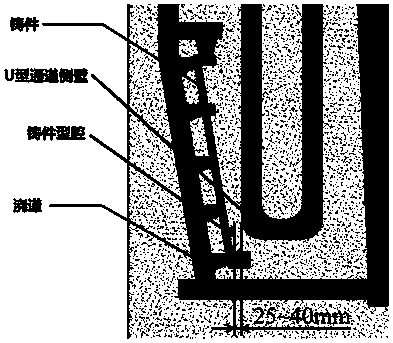

[0022] In this embodiment, the aluminum alloy precision casting solidification defect control method, the casting is a cabin body, and the outline size is The wall thickness is 2.5mm, and the material is ZL114A aluminum-silicon series cast aluminum alloy. The investment gypsum type vacuum pressure casting process is adopted. The steps are as follows:

[0023] When pouring gypsum into the investment casting cabin wax model, a "U" type wax sample with a diameter of 30 mm is set in the mold, and the distance between the side wall of the "U" type wax sample and the mold cavity is 30 mm. After dewaxing at 200°C and high-temperature roasting at 700°C, the mold temperature is lowered to 300°C, and the "U"-shaped channel is filled with iron powder with a particle size of 40 mesh. Before the ZL114A melt is poured, the air pipe is firmly connected to the side of the "U" channel near the casting, and after the filling is completed under the vacuum condition of -0.05MPa, the nitrogen gas...

Embodiment 2

[0026] In this embodiment, the solidification defect control method of aluminum alloy precision casting, the casting is a shell type, and the outline size is The wall thickness of the main body is 3.0mm, and the material is ZL205A aluminum-copper cast aluminum alloy. The investment plaster type gravity casting process is adopted. The steps are as follows:

[0027] When pouring gypsum into the investment casting shell wax mold, a "U"-shaped wax sample with a diameter of 40mm is set in the mold, and the distance between the side wall of the "U"-shaped wax sample and the mold cavity is 20mm. After dewaxing at 200°C and high-temperature roasting at 700°C, the mold temperature is lowered to 250°C, and the "U"-shaped channel is filled with chromite sand with a particle size of 20 mesh. Before the ZL205A melt is poured, the air pipe is firmly connected to the side of the "U" channel close to the casting. After the filling is completed under gravity, the air pipe is immediately fed w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Elongation after break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com