Neutron shielding material and preparation method thereof

A technology of shielding materials and neutrons, which is applied in the field of neutron shielding materials and its preparation, can solve the problems of poor thermal conductivity and flame retardancy, unsuitable pouring, poor molding performance, etc., achieve good flame retardancy, accelerate solidification speed, The effect of less pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

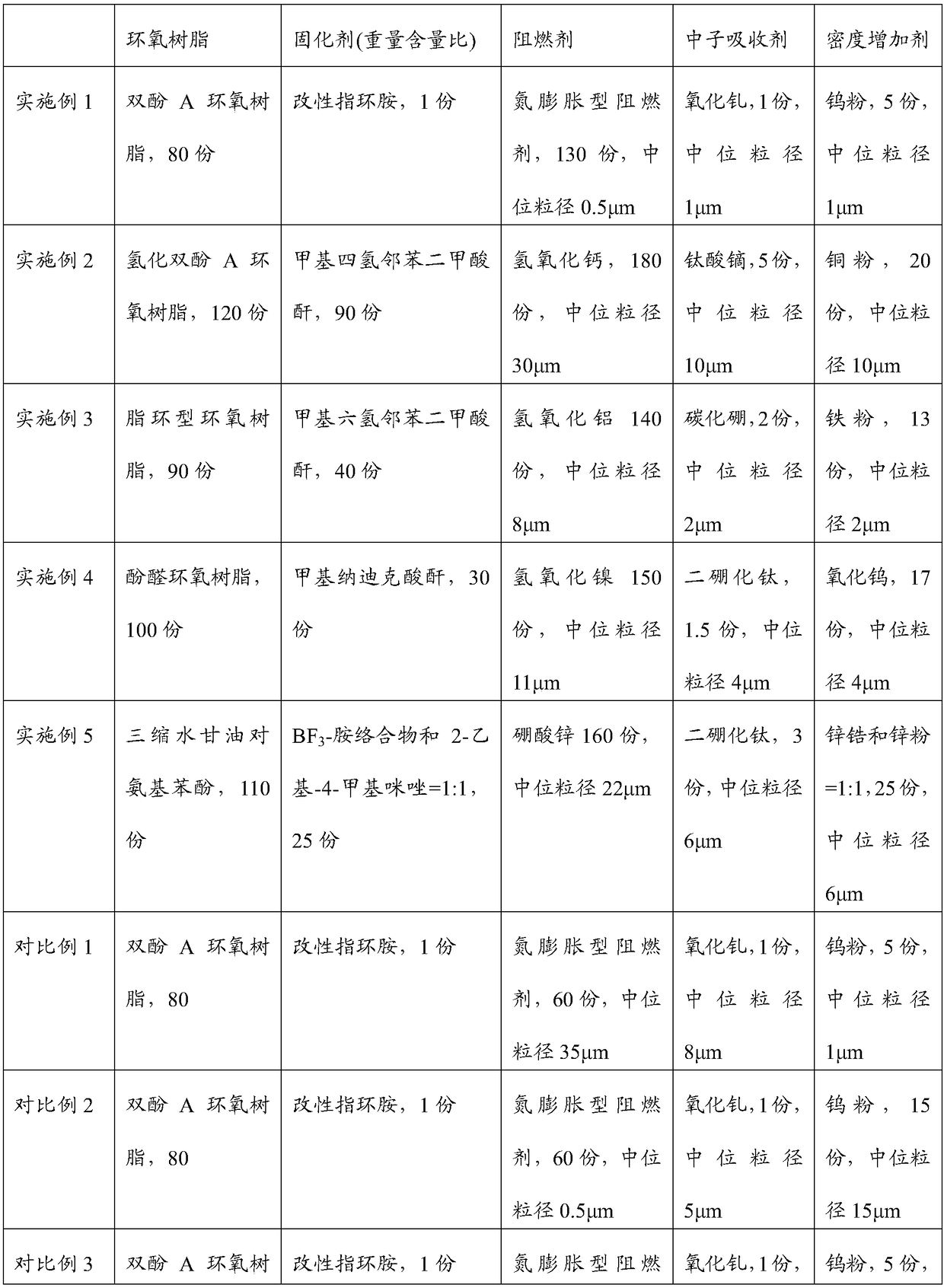

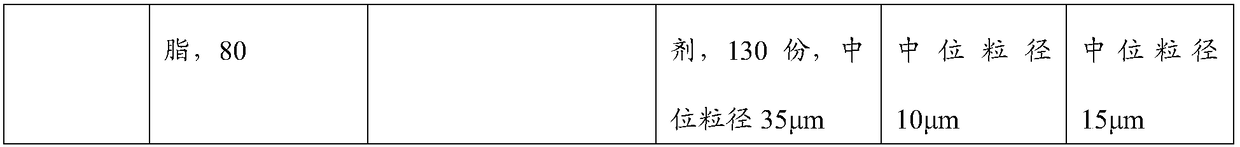

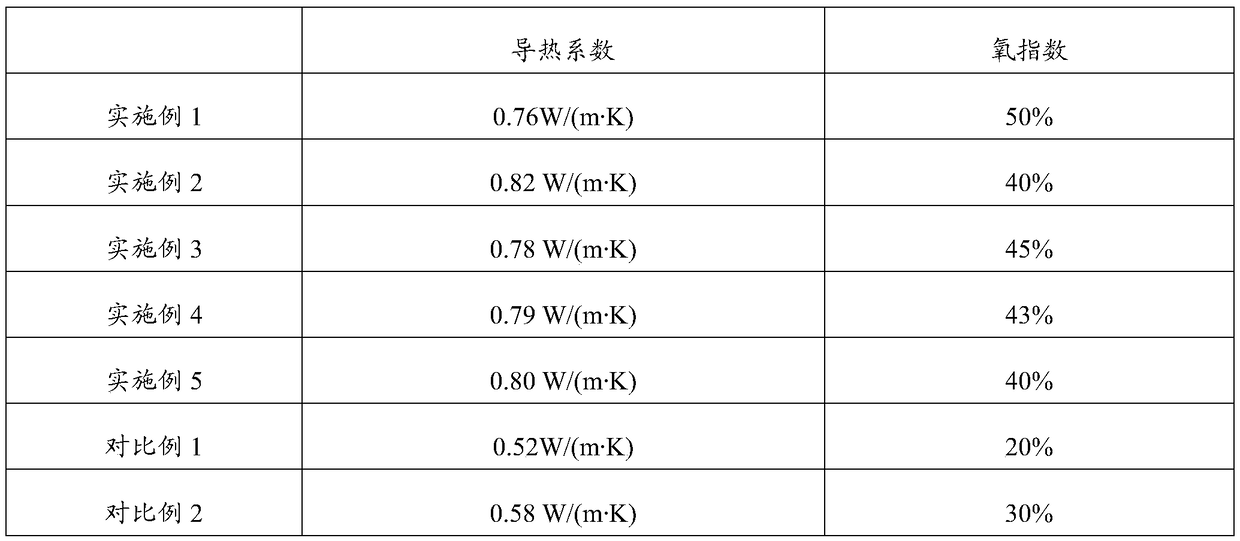

Examples

preparation example Construction

[0023] A preparation method for preparing the above-mentioned neutron shielding material comprises the following steps:

[0024] (1) Carry out vacuum mixing with epoxy resin and some flame retardants, the vacuum mixing time depends on the specific situation and selects a specific value from 10-30min;

[0025] (2) Add another part of flame retardant, density increasing agent, neutron absorber in (1), and carry out described vacuum mixing and defoaming treatment, defoaming treatment time, mixing temperature are from 2-5h respectively, Choose a specific value from 30-50°C depending on the specific situation;

[0026] (3) Add curing agent in (2) and carry out vacuum mixing and make mixture;

[0027] (4) the mixture in (3) is poured into a vacuum mold;

[0028] (5) After (4), put the vacuum mold into an oven for curing treatment. The curing temperature and curing time are respectively selected from 30-50°C and 24-28h according to the actual situation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com