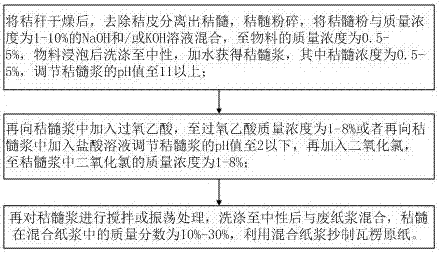

Method for utilizing straw and waste paper pulp to prepare high strength corrugated base paper

A technology for corrugated base paper and waste paper pulp, which is applied in textiles and papermaking, pulping with organic compounds, pulping with halogen compounds, etc. Conducive to energy saving and consumption reduction, the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

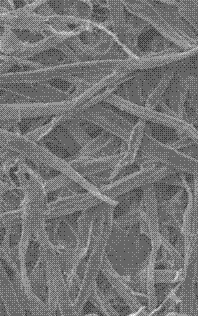

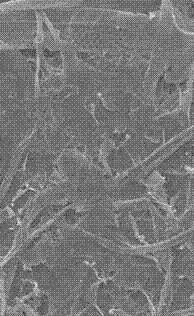

Image

Examples

Embodiment 1

[0040] High-strength corrugated base paper was prepared from corn stalks and waste paper pulp. After the corn stalks are dried in the sun, remove the husks to separate the straw, crush the straw and pass through a 20-mesh sieve, immerse the straw powder in 1% NaOH solution until the material concentration is 1%, soak it at 20°C for 4 hours, and then wash it with water until medium. Add water to obtain straw pulp until the mass concentration of straw is 2%, add peracetic acid until the concentration is 3%, stir at 25°C for 3 hours, the speed of the stirring rotor is 200 rpm, and wash until neutral , to obtain the treated straw pulp, mix straw pulp and waste paper pulp, until the mass fraction of straw pulp in the mixed pulp is 10%, use the mixed pulp to prepare corrugated base paper with a weight of 130g / m2, and use it under the same conditions Compared with the corrugated base paper made from pure waste paper pulp, under normal temperature and pressure, the tensile strength of...

Embodiment 2

[0042] High-strength corrugated base paper was prepared from corn stalks and waste paper pulp. After the corn stalks are air-dried, remove the husks to separate the straw, pass the crushed straw through a 20-mesh sieve, immerse the straw powder in 5% KOH solution until the material concentration is 1.5%, and soak at 35°C for 6 hours. Then wash with water until neutral, add water until the mass concentration of straw is 1%, add peracetic acid until its concentration is 2%, shake and treat at 35°C for 6 hours, and the rotating speed is 100rpm, wash until neutral, and obtain the treated Straw pulp, mix straw pulp and waste paper pulp, until the mass fraction of straw in the mixed pulp is 20%, use the mixed pulp to make corrugated base paper with a weight of 150g / m2, and make it with pure waste paper pulp under the same conditions Compared with corrugated base paper, under normal temperature and pressure, the tensile strength of the paper increased by 87%, and the ring compressive...

Embodiment 3

[0044] High-strength corrugated base paper was prepared from corn stalks and waste paper pulp. After the corn stalks are dried in the sun, remove the husks and separate the pith, crush the pith and pass through a 20-mesh sieve, then immerse the straw pith powder in a mixed solution with a mass concentration of 3% of NaOH and KOH until the material concentration is 2.5%. Soak at 45°C for 2 hours, wash the straw with water to neutral, add water until the mass concentration of the straw is 2.5%, add hydrochloric acid solution to adjust the pH value of the straw pulp to below 2, then add chlorine dioxide, until the straw pulp The mass concentration of chlorine dioxide in the medium is 6%, stirred at 60°C for 15 hours, the speed of the stirring rotor is 20rpm, washed to neutral, and the treated straw pulp is obtained, and the straw pulp and waste paper pulp are mixed until mixed The mass fraction of straw in the pulp is 30%, and the corrugated base paper with a weight of 160g / m2 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com