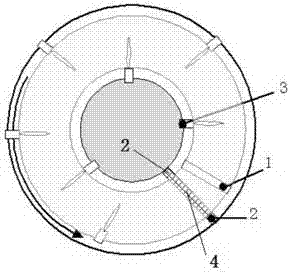

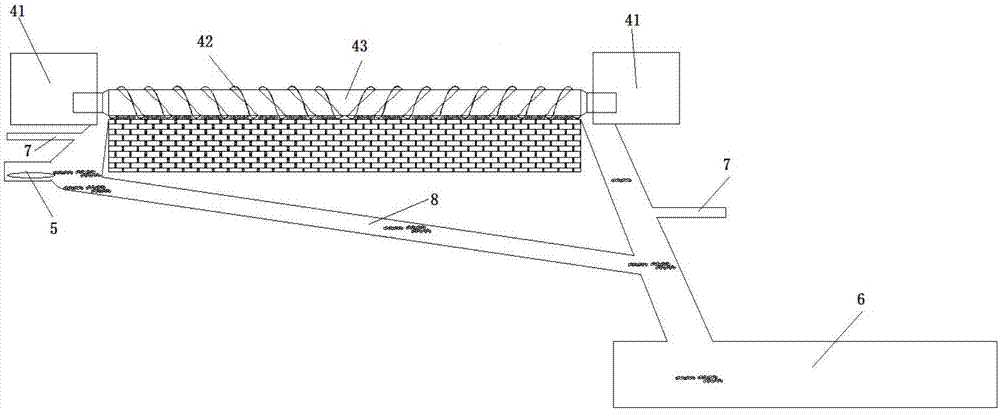

Rotary hearth furnace

A rotary hearth furnace and furnace body technology, applied in the direction of rotary drum furnaces, furnaces, furnace types, etc., can solve problems such as furnace bottom, furnace wall thickening, jamming, damage to the furnace body transmission system, and materials that cannot be completely removed, and achieve Prevent the furnace bottom and the furnace wall from being stuck, prolong the life of the equipment, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be described in more detail below with reference to the drawings and examples, so as to better understand the solutions of the present invention and the advantages of various aspects. However, the specific embodiments and examples described below are for the purpose of illustration only, rather than limiting the present invention.

[0021] In the present invention, unless otherwise specified and limited, the terms "connected" or "connected" should be interpreted in a broad sense, for example, it may be mechanically connected or electrically connected; it may be directly connected or through an intermediary An indirect connection may be an internal communication between two elements or an interaction relationship between two elements, unless otherwise clearly defined. Those of ordinary skill in the art can understand the specific meanings of the above terms in the present invention according to specific si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com