Pipeline fire control liquid and application thereof

A fire-fighting fluid and pipeline technology, applied in the chemical industry, can solve problems such as anti-rust, anti-corrosion, lack of flame retardancy, and affect the use of fire-fighting fluid, and achieve long service life and good antifreeze effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

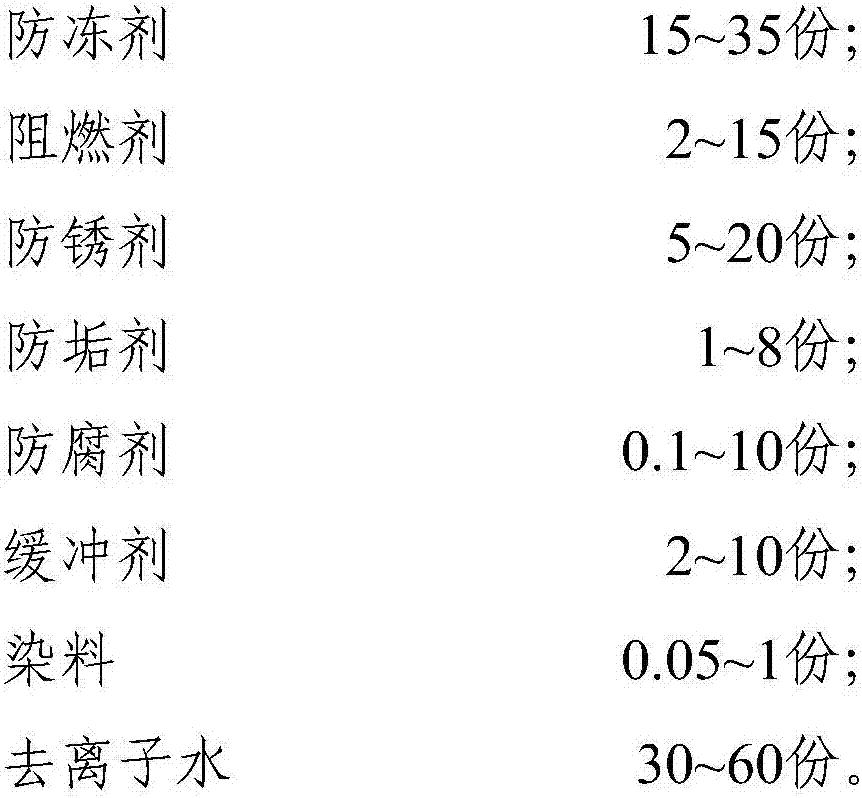

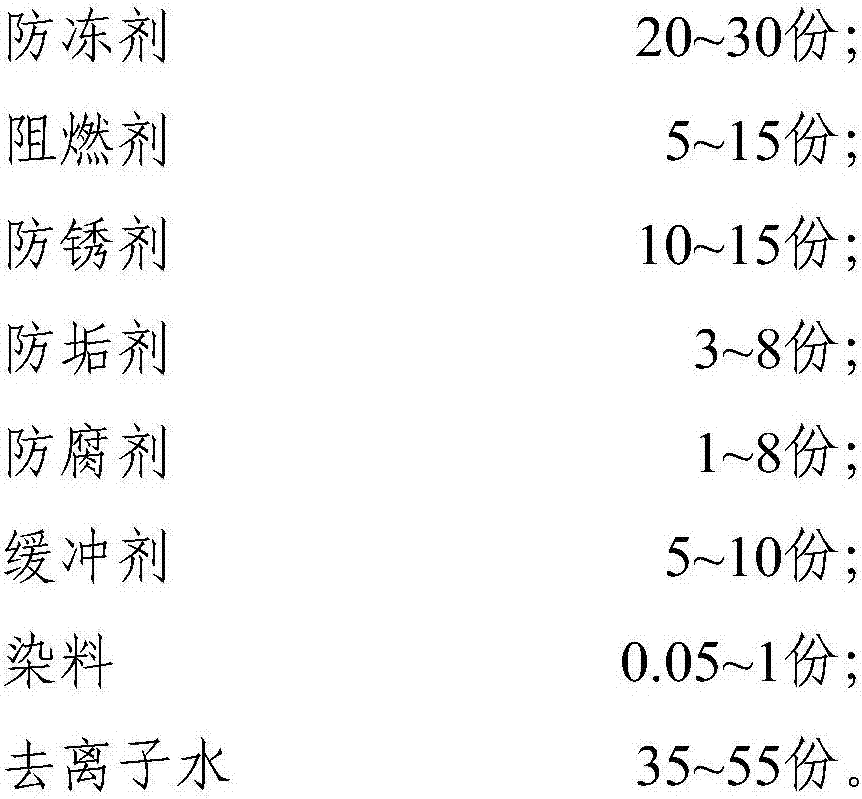

Method used

Image

Examples

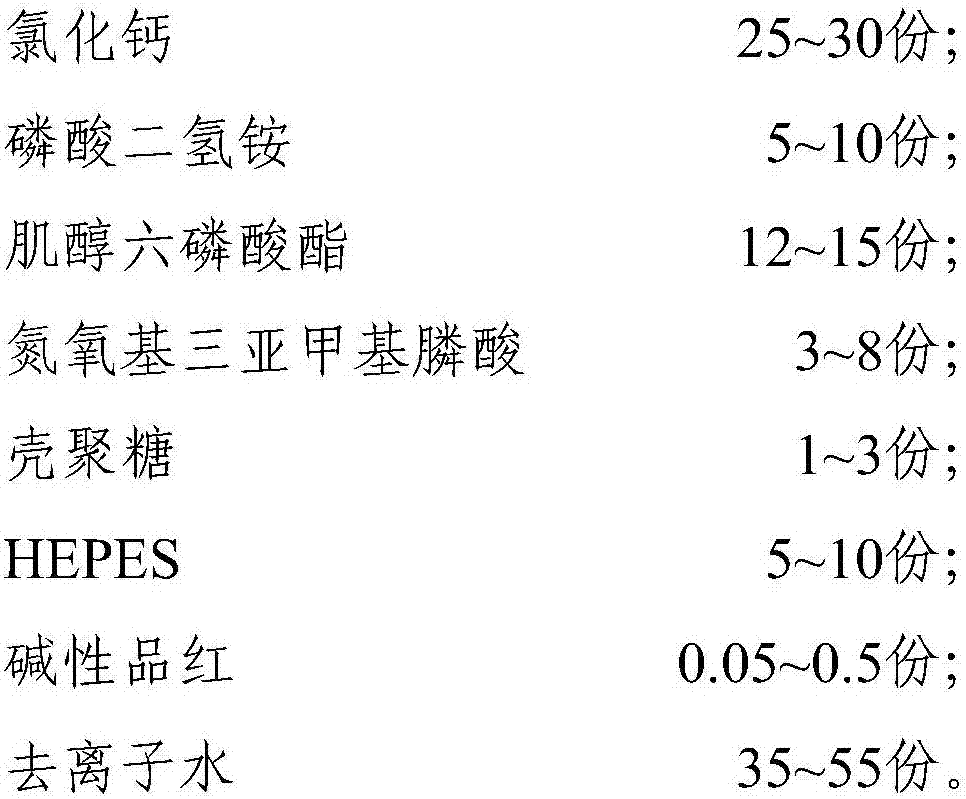

Embodiment 1

[0028] A pipeline fire-fighting fluid, which consists of 15g calcium chloride, 12g phosphate, 8g thiophosphate, 6g sodium tripolyphosphate, 5g dimethyl fumarate, 8g HEPES, 0.5g basic fuchsin, Ionized water 45.5g.

Embodiment 2

[0030] A pipeline fire-fighting fluid, which consists of 21g calcium chloride, 11g dibromooctanediol, 10g alkyl alcohol amide, 7g pentaerythritol ester, 3g hydrolyzed polymaleic anhydride, 1g copper hydroxide, 7g Tricine, and alkaline products Red 0.8g, deionized water 39.2g.

Embodiment 3

[0032] A pipeline fire fighting fluid, which consists of 25g calcium chloride, 8g dibromooctanediol phosphate, 15g 1,2-diethoxysilyl ethane, and 5g ethylenediaminetetramethylenephosphonic acid , 2g copper sulfate, 8g triethanolamine, 0.4g basic fuchsin, 36.6g deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com