Preparation method of water-insoluble quaternary ammonium salt

A quaternary ammonium salt, water-insoluble technology, applied in botany equipment and methods, chemicals for biological control, biocides, etc., can solve the problems of non-renewable recycling, toxicity, etc., and achieve excellent bactericidal performance and bactericidal performance Enhanced, large specific surface area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

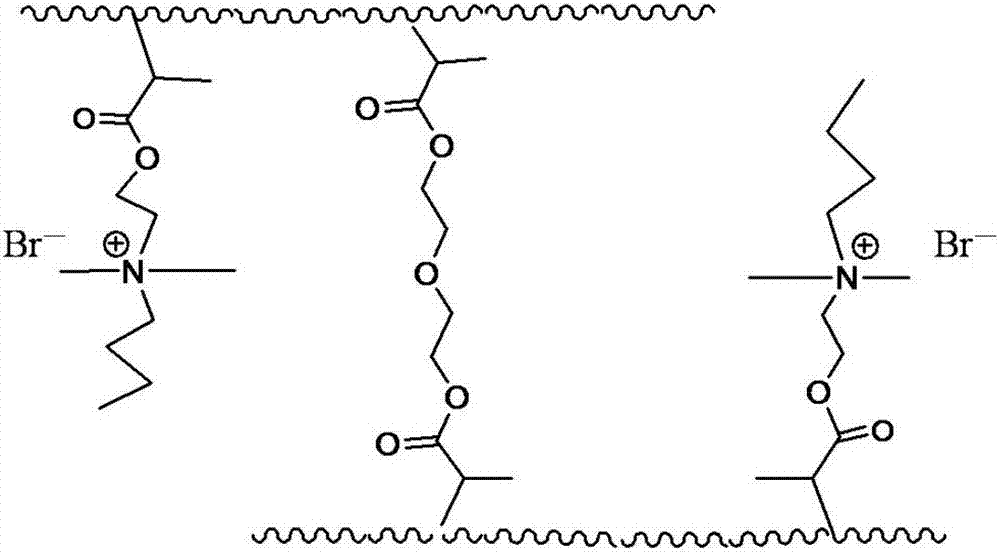

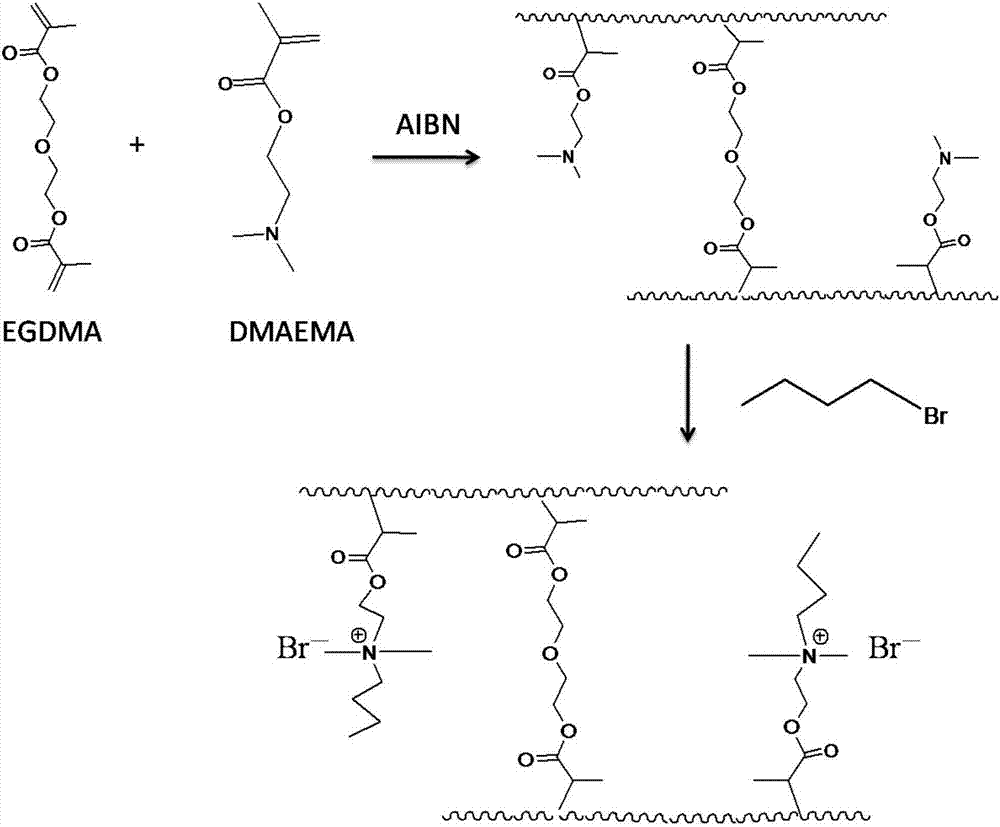

[0032] A kind of preparation method of water-insoluble type quaternary ammonium salt is:

[0033] Mix 90g dimethylaminoethyl methacrylate (DMAEMA), 10g ethylene glycol dimethacrylate (EGDMA), and 40g ethyl acetate evenly, then add to gelatin mass concentration 1% and sodium chloride mass concentration 15% Then add 1 g of azobisisobutyronitrile (AIBN), heat to 65° C. and stir for 4 hours, then raise the temperature to 75° C. to continue the reaction for 4 hours. After the reaction is completed, filter and collect the precipitate. Wash with purified water, then extract with ethanol, and dry to obtain a resin matrix.

[0034] Take 50 g of the above-mentioned dried resin matrix and put it into a three-necked flask, purging with nitrogen for 5 minutes, add 100 g of brominated n-butane solution with a mass concentration of 50%, raise the temperature to 90° C., and stir for 18 hours. After the reaction is completed, filter with suction to collect the precipitate, wash it with ethano...

Embodiment 2

[0036] A kind of preparation method of water-insoluble type quaternary ammonium salt is:

[0037] Mix 80g of dimethylaminoethyl methacrylate (DMAEMA), 20g of ethylene glycol dimethacrylate (EGDMA), and 50g of ethyl acetate evenly, then add to gelatin mass concentration 1% and sodium chloride mass concentration 15% Then add 1 g of azobisisobutyronitrile (AIBN), heat to 65° C. and stir for 4 hours, then raise the temperature to 75° C. to continue the reaction for 4 hours. After the reaction is completed, filter and collect the precipitate. Washing with purified water, followed by extraction with ethanol, and drying to obtain a resin matrix.

[0038] Take 50 g of the above-mentioned dried resin matrix and put it into a three-necked flask, purging with nitrogen for 5 minutes, add 100 g of brominated n-butane solution with a mass concentration of 50%, raise the temperature to 90° C., and stir for 18 hours. After the reaction is completed, filter with suction to collect the precipi...

Embodiment 3

[0040] A kind of preparation method of water-insoluble type quaternary ammonium salt is:

[0041] 80g dimethylaminoethyl methacrylate (DMAEMA), 20g ethylene glycol dimethacrylate (EGDMA), 25g ethyl acetate, 25g lauryl alcohol were mixed evenly, then added to gelatin mass concentration 1% and chlorinated Add 1 g of azobisisobutyronitrile (AIBN) to an aqueous solution with a sodium mass concentration of 15%, heat to 65° C. and stir for 4 hours, then raise the temperature to 75° C. and continue the reaction for 4 hours. After the reaction is completed, filter and collect the precipitate. Washing with purified water, followed by extraction with ethanol, and drying to obtain a resin matrix.

[0042] Take 50 g of the above-mentioned dried resin matrix and put it into a three-necked flask, purging with nitrogen for 5 minutes, add 100 g of brominated n-butane solution with a mass concentration of 50%, raise the temperature to 90° C., and stir for 18 hours. After the reaction is compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com