A curved panel processing tool and processing method

A processing method and technology for curved panels, which are applied to workpiece clamping devices, manufacturing tools, etc., can solve the problems of inability to process the profile in the workshop at one time, reduction of steel toughness, enlargement of curved panels, and deformation of hyperbolic panels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Exemplary embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention can have various changes in different embodiments without departing from the scope of the present invention, and the descriptions and drawings therein are essentially used for illustration rather than limitation this invention.

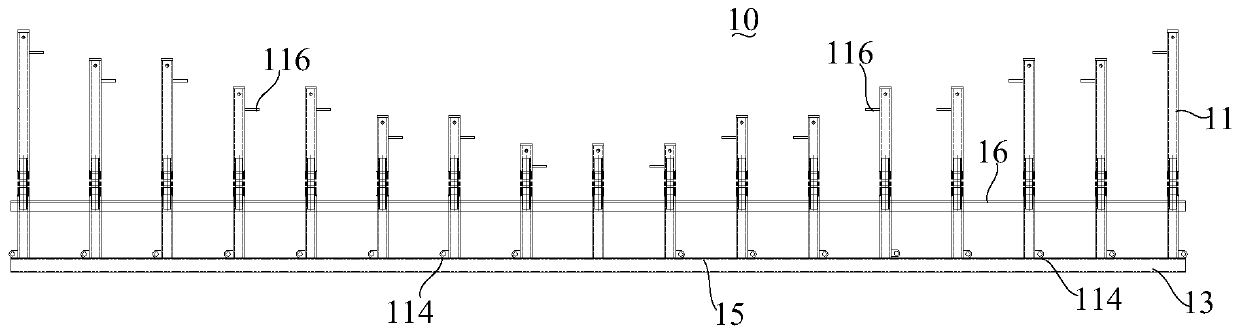

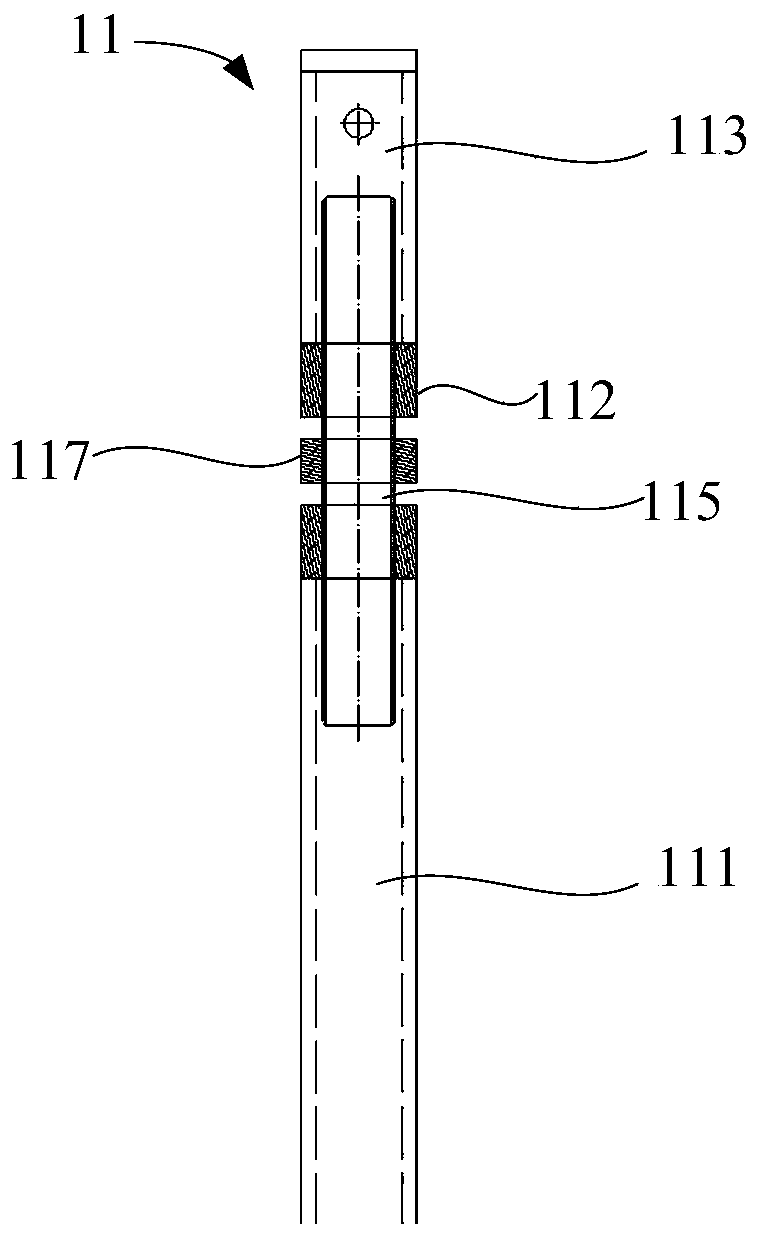

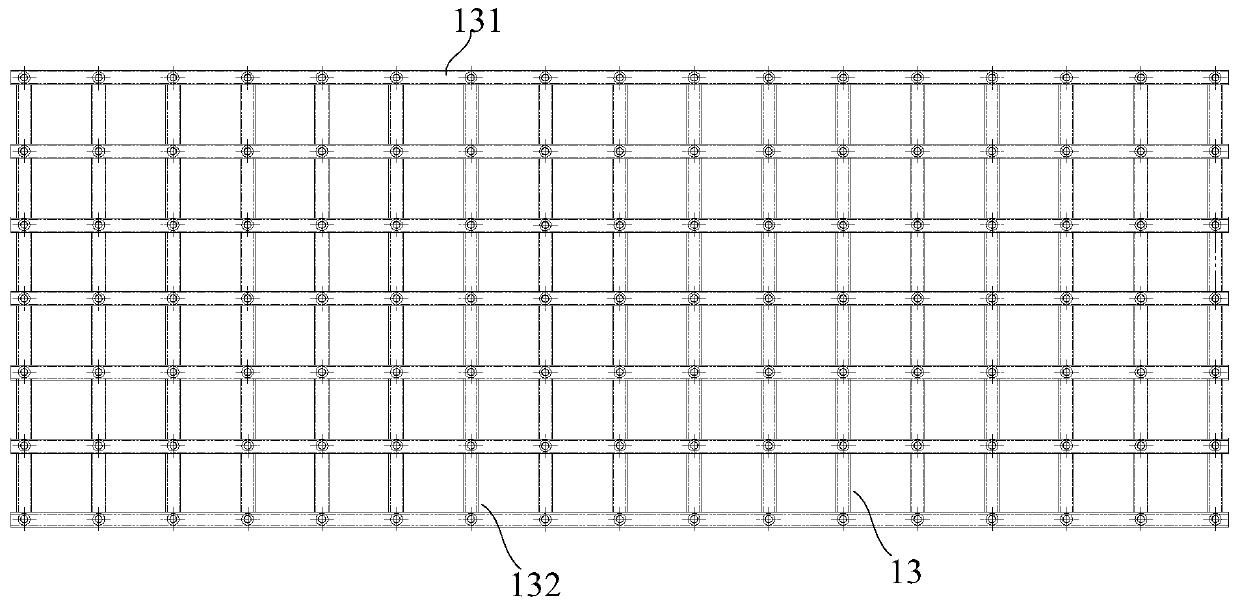

[0038] The present invention provides a curved panel processing tool 10 for performing curvature correction on the curved panel, and fixing and processing the curved panel. The curved panel processing tool 10 is to use spherical flat steel to make a frame structure platform with a width of 3 meters and a length of 8 meters. The curved panel processing tool 10 can be applied to most existing semi-submersible drilling platforms and semi-submersible living platforms. Among them, the curved panel can be a hyperbolic panel with specifications of 2.5m*8m, 3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com