Catalyst composition for allantoin preparation and preparation method of catalyst composition

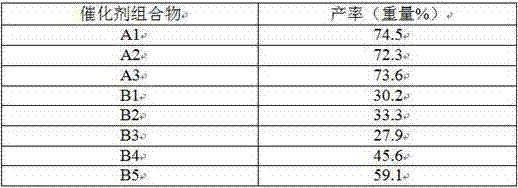

A technology of catalyst and allantoin, which is applied in the field of allantoin preparation catalyst composition and its preparation, can solve the problems of polluting the environment, not very superior catalytic effect, and low allantoin yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

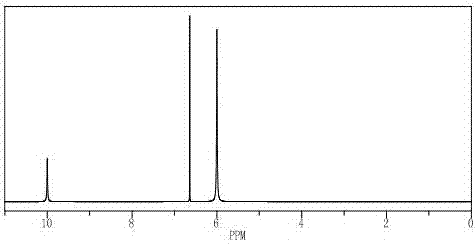

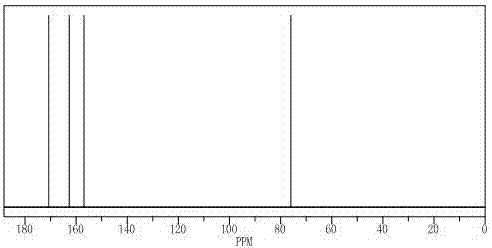

Image

Examples

preparation example Construction

[0017] The invention provides a method for preparing a catalyst composition for preparing allantoin, comprising:

[0018] 1) Hydrothermal reaction of molecular sieve, tetrabutyl titanate, cerium source, sodium tungstate, amino acid, ethanol and water to prepare modified molecular sieve;

[0019] 2) Soak the modified molecular sieve in acid solution to obtain active molecular sieve;

[0020] 3) Ball milling the active molecular sieve, alumina, diatomaceous earth, sodium dodecylbenzenesulfonate and rosin to prepare allantoin to prepare a catalyst composition.

[0021] In step 1) of the present invention, the amount of each material can be selected within a wide range, but in order to make the prepared catalyst composition have more excellent catalytic performance, preferably, in step 1), molecular sieve, titanic acid The weight ratio of tetrabutyl ester, cerium source, sodium tungstate, amino acid, ethanol and water is 10:1.2-1.5:0.2-0.4:0.2-0.5:0.08-0.12:5-8:10-15.

[0022] I...

Embodiment 1

[0032] 1) Molecular sieve, tetrabutyl titanate, cerium source (cerium oxide), sodium tungstate, amino acid, ethanol, water are subjected to hydrothermal reaction according to the weight ratio of 10:1.3:0.3:0.4:0.10:7:13 (reaction The temperature is 210°C, and the reaction time is 6h) to prepare modified molecular sieves;

[0033] 2) Soak the modified molecular sieve and acid solution (pH 5.8, hydrochloric acid aqueous solution) according to the weight ratio of 10:40 (soaking temperature is 40°C, soaking time is 20h) to prepare active molecular sieve;

[0034] 3) Active molecular sieve, alumina (particle size: 0.08mm), diatomaceous earth (particle size: 0.08mm), sodium dodecylbenzenesulfonate, and rosin are mixed according to the weight ratio of 10:1.8:0.5:0.7:8 Ball milling (the mass ratio of large balls to small balls is 3:1, the mass ratio of balls to materials is 20:1, the rotational speed is 2000 rpm, and the ball milling time is 50 min) is used to prepare allantoin and pr...

Embodiment 2

[0036] 1) Molecular sieve, tetrabutyl titanate, cerium source (or cerium nitrate), sodium tungstate, amino acid, ethanol, water are subjected to hydrothermal reaction according to the weight ratio of 10:1.2:0.2:0.2:0.08:5:10 ( The reaction temperature is 200°C, and the reaction time is 4h) to prepare modified molecular sieves;

[0037] 2) Soak the modified molecular sieve and acid solution (pH 5.5, phosphoric acid aqueous solution) in a weight ratio of 10:30 (soaking temperature is 30°C, soaking time is 12h) to prepare active molecular sieve;

[0038] 3) Active molecular sieve, alumina (particle size: 0.05mm), diatomaceous earth (particle size: 0.05mm), sodium dodecylbenzenesulfonate, and rosin are mixed according to the weight ratio of 10:1.5:0.2:0.5:5 Ball milling (the mass ratio of large balls to small balls is 3:0.8, the mass ratio of balls to materials is 20:0.8, the rotational speed is 1800 rpm, and the ball milling time is 40 min) is carried out to obtain allantoin and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com