Double pole film with hyperbranched polymericcompound as the intermediate boundary layer and method of preparing the same

A technology of hyperbranched polymers and bipolar membranes, applied in chemical instruments and methods, membrane technology, semipermeable membrane separation, etc., can solve the problems of membrane performance degradation, cumbersome methods, and increased voltage drop, and achieve improved water dissociation performance , lower water dissociation voltage, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

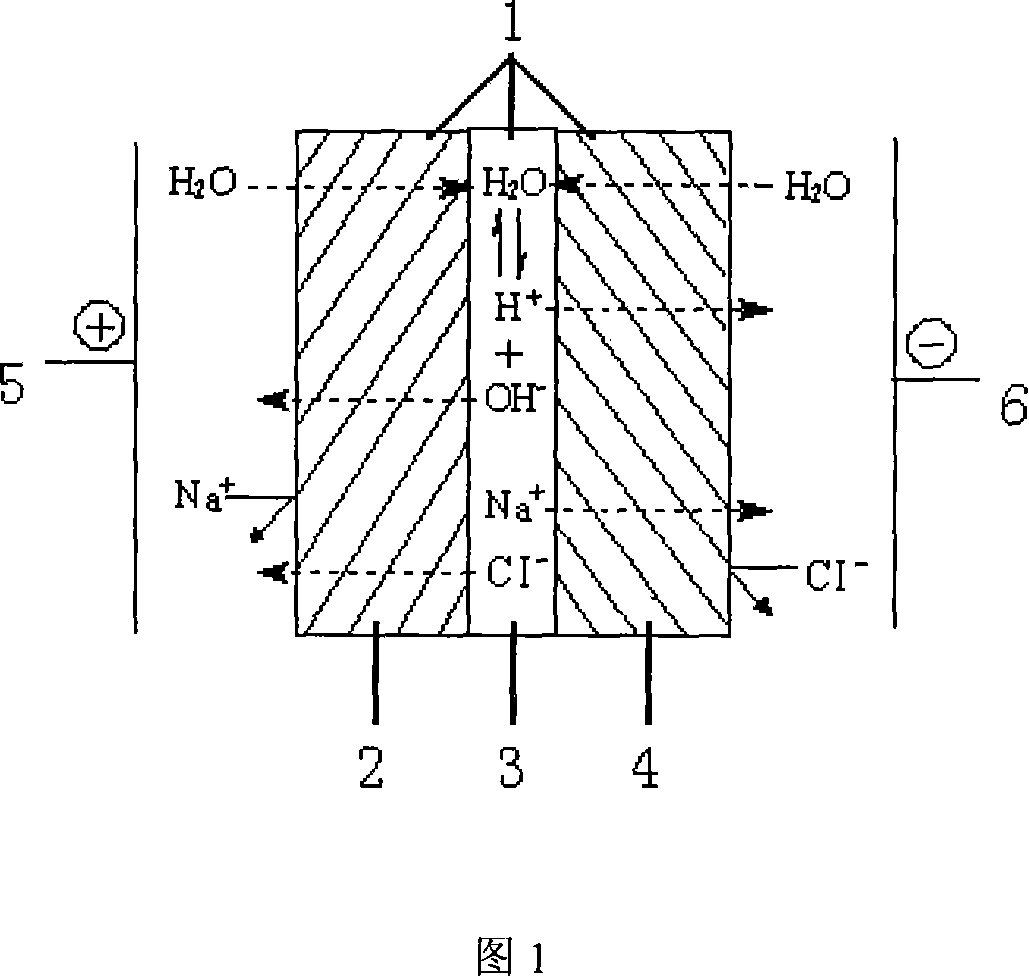

[0017] First prepare the bipolar membrane with the hyperbranched polymer of the present invention as the intermediate interface layer, and the specific steps are as follows:

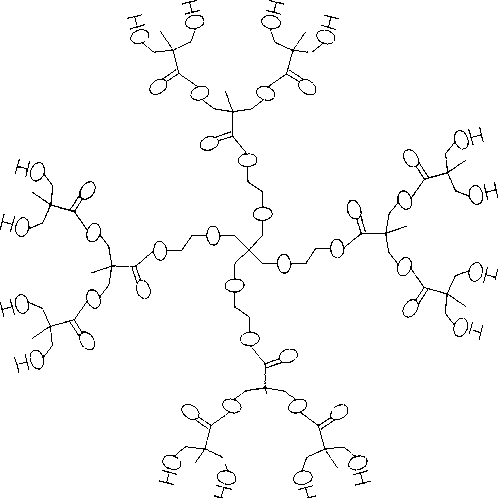

[0018] Boltorn _ H20 (manufactured by PerstorpGroup, brand H series products, including Boltorn _ H20, Boltorn _ H30, Boltorn _ H30, are the 2nd, 3rd, and 4th generation aliphatic hyperbranched polyesters with pentaerythritol as the core unit and 2,2-dimethylol propionic acid as the branching unit. Concrete structure is shown in following formula (I), formula (II), formula (III):

[0019]

[0020] Formula (I): Boltorn _ H20

[0021]

[0022] Formula (II): Boltorn _ H30

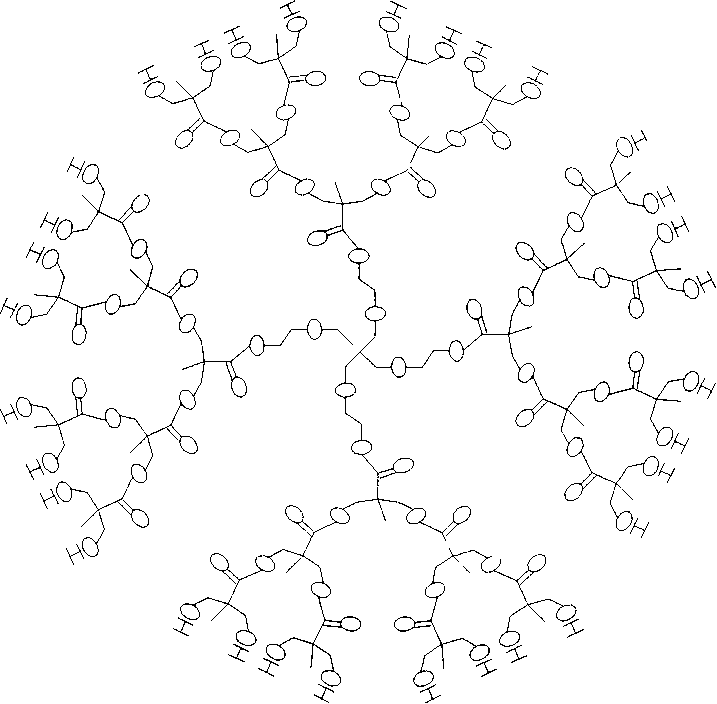

[0023]

[0024] Formula (III): Boltorn _ H40

[0025] First prepare the hyperbranched polymer Boltorn with a concentration of 5.0mg / mL _ H20 aqueous solution;

[0026] Soak the heterogeneous anion exchange membrane whose surface has been washed by 1M NaOH, 1M HCL and distilled water in the aqueous solution of the hype...

Embodiment 2

[0039] The preparation process of the bipolar membrane is the same as in Example 1, except that the temperature is kept constant at 40 degrees Celsius when the water is dissociated. The prepared bipolar membrane is at 40 degrees Celsius, 0.5mol / L Na 2 SO 4 In aqueous solution, the current density is 1200A / m 2 The voltage drop on both sides of the membrane under the same conditions is 3.8V, while under the same conditions without Boltorn _ The voltage drop on both sides of the bipolar membrane prepared by the anion exchange membrane soaked in H20 is 5.4V, that is, the adsorption concentration is 5.0mg / ml with pentaerythritol as the core unit and 2,2-dimethylolpropionic acid as the branched The second generation hyperbranched macromolecule Boltorn _ Compared with the bipolar membrane with H20 aqueous solution as the intermediate interface layer and the bipolar membrane without adding catalytic material interface layer, at 40 degrees Celsius, 0.5mol / LNa 2 SO 4 In aqueous sol...

Embodiment 3

[0041] The preparation process of bipolar membrane is similar to embodiment 1, just the Boltorn of the 2nd generation that concentration is 5.0mg / mL _ The H20 aqueous solution was replaced with the 3rd generation Boltorn at a concentration of 5 mg / mL _ H30 aqueous solution. The prepared bipolar membrane is at 25 degrees Celsius, 0.5mol / LNa 2 SO 4 In aqueous solution, the current density is 1200A / m 2 The voltage drop across the membrane under the film is 3.4V without Boltorn _ The voltage drop on both sides of the bipolar membrane prepared by the anion exchange membrane soaked in H30 is 5.3V, that is, with the adsorption concentration of 5mg / ml, pentaerythritol is the core unit and 2,2-dimethylolpropionic acid is the branch unit. The third generation hyperbranched macromolecule Boltorn _ Compared with the bipolar membrane with H30 aqueous solution as the intermediate interface layer and the bipolar membrane without adding catalytic material interface layer, at 25 degrees C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com