A kind of bipolar film of surface loading graphyne and preparation method thereof

A surface-loaded, graphdiyne technology, applied in diaphragms, electrolytic components, electrolytic processes, etc., can solve the problems of low water dissociation efficiency of bipolar membranes, short working life of bipolar membranes, and large water dissociation voltage, etc., to improve chemical stability. The effect of improving the mechanical properties and promoting the dissociation of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Weigh 6.0g PhBr 6 , 4.0g CaC 2 Stainless steel balls different in diameter and size were added to a stainless steel tank filled with 100 milliliters of absolute ethanol, and a planetary ball mill was used to operate at a speed of 450 rpm for 15 hours. The mixture was washed, filtered, and dried to obtain black powder graphdiyne. The graphdiyne powder was made into a dilute solution, fixed on the surfaces of both sides of the bipolar membrane by coating, and dried naturally to obtain a bipolar membrane with a total thickness of 80.8nm.

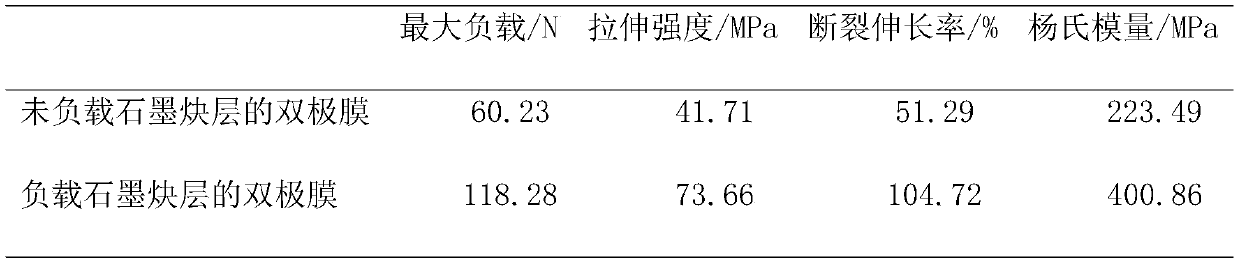

[0019] In order to further demonstrate the effect of the bipolar membrane of the present invention, the present invention uses an electronic universal testing machine to test its mechanical properties of Young's modulus, tensile strength, maximum load and elongation at break. At the same time, the bipolar membrane of the present invention is used as the diaphragm of the cathode and anode chambers to conduct water dissociation under the ...

Embodiment 2

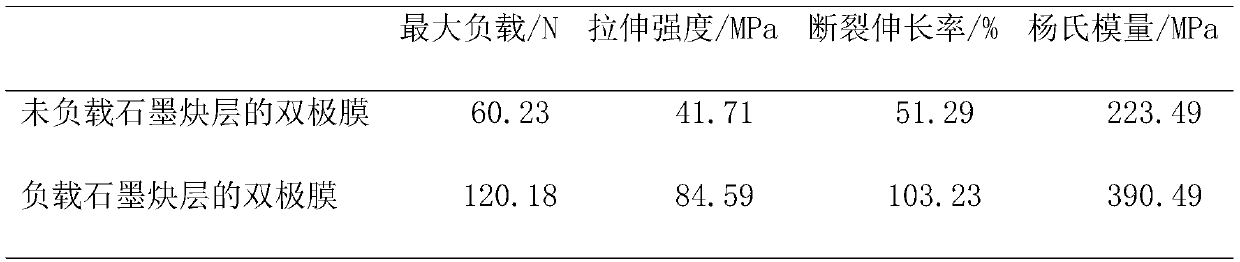

[0024] Weigh 9.0g PhBr 6 , 6.0g CaC 2 Stainless steel balls with different diameters were added to a stainless steel tank filled with 150 ml of absolute ethanol, and the planetary ball mill was operated at a speed of 450 rpm for 18 hours, and the mixture was washed, filtered, and dried to obtain black powder graphyne. The graphdiyne powder was formulated into a dilute solution, fixed on the surfaces of both sides of the bipolar membrane by electrophoresis, and dried naturally to obtain a bipolar membrane with a total thickness of 92.3 nm. The electronic universal testing machine was used to test the mechanical properties such as Young's modulus and tensile strength. At the same time, the bipolar membrane of the present invention is used as the diaphragm of the cathode and anode chambers to conduct water dissociation under the action of an external DC electric field, and the water dissociation voltage, water dissociation efficiency and service life of the bipolar membrane are ...

Embodiment 3

[0029] Weigh 13.5g PhBr 6 , 9.0g CaC 2 Stainless steel balls with different diameters were added to a stainless steel tank filled with 150 ml of absolute ethanol, and the planetary ball mill was operated at a speed of 450 rpm for 18 hours, and the mixture was washed, filtered, and dried to obtain black powder graphyne. The graphdiyne powder was prepared into a dilute solution, fixed on the surfaces of both sides of the bipolar membrane by electrophoresis, and dried naturally to obtain a bipolar membrane with a total thickness of 95.6 nm. The electronic universal testing machine was used to test the mechanical properties such as Young's modulus and tensile strength. At the same time, the bipolar membrane of the present invention is used as the diaphragm of the cathode and anode chambers to conduct water dissociation under the action of an external DC electric field, and the water dissociation voltage, water dissociation efficiency and service life of the bipolar membrane are s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com