Preparation method and application of a carbon nanofiber-hydrotalcite composite adsorbent

A carbon nanofiber, composite material technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, water pollutants, etc. and adsorption rate, etc., to achieve the effects of excellent physical and chemical properties, good environmental stability, and fast reaction kinetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

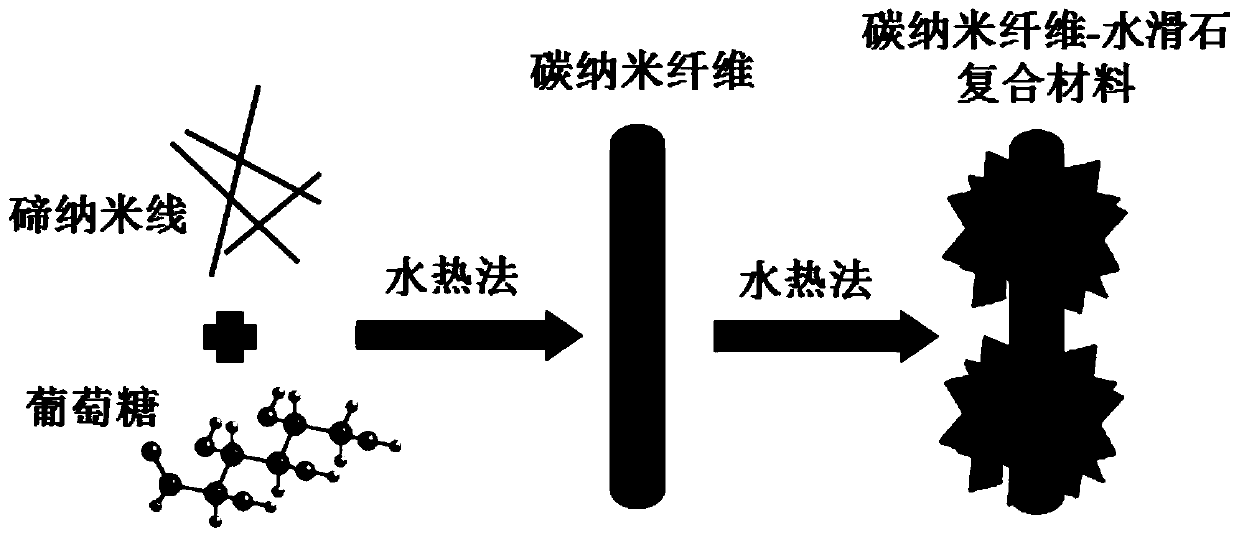

[0029] The present invention provides a kind of preparation method of carbon nanofiber-hydrotalcite composite adsorbent, described method comprises the following steps:

[0030] (1) Preparation of carbon nanofibers;

[0031] (2) Preparation of carbon nanofiber-hydrotalcite composites.

[0032] Wherein, the preparation of the carbon nanofibers described in step (1) comprises the following steps:

[0033] 1) Preparation of tellurium nanowires: Dissolve 1.0g polyvinylpyrrolidone in 35mL ultrapure water at room temperature, add 0.0922g sodium tellurite, stir for 15-30min, then add 1.7mL hydrazine hydrate and 3.4mL ammonia water, Stir for another 15-30 minutes; transfer the above solution to a 50mL reactor, heat at 180°C for 4-6 hours, then quickly cool the reactor to room temperature with water;

[0034] 2) Preparation of carbon nanofibers: Take 10 mL of the tellurium nanowire solution prepared in step 1), add 30 mL of acetone, and centrifuge at 8000 rpm for 30 to 60 min; wash t...

Embodiment 1

[0043] A preparation method of carbon nanofiber-hydrotalcite composite adsorbent, comprising the following steps:

[0044] (1) Preparation of carbon nanofibers, the steps are as follows:

[0045] 1) Preparation of tellurium nanowires: at room temperature, 1.0 g of polyvinylpyrrolidone was dissolved in 35 mL of ultrapure water, 0.0922 g of sodium tellurite was added, and stirred for 15 min. Then add 1.7mL hydrazine hydrate and 3.4mL ammonia water, and stir for 15min. Transfer the above solution to a 50mL reaction kettle, heat at 180°C for 4h, then take out the reaction kettle, and quickly cool it to room temperature with tap water;

[0046] 2) Preparation of carbon nanofibers: Take 10 mL of the prepared tellurium nanowire solution, add 30 mL of acetone, and centrifuge at 8000 rpm for 30 min. The resulting precipitate was washed with a small amount of water to remove residual polyvinylpyrrolidone, and redispersed into 60 mL of ultrapure water. Add 1.0g of glucose and stir to ...

Embodiment 2

[0051] A preparation method of carbon nanofiber-hydrotalcite composite adsorbent, comprising the following steps:

[0052] (1) Preparation of carbon nanofibers, the steps are as follows:

[0053] 1) Preparation of tellurium nanowires: at room temperature, 1.0 g of polyvinylpyrrolidone was dissolved in 35 mL of ultrapure water, 0.0922 g of sodium tellurite was added, and stirred for 20 min. Then add 1.7mL hydrazine hydrate and 3.4mL ammonia water, and stir for another 20min. Transfer the above solution to a 50mL reaction kettle, heat at 180°C for 5h, then take out the reaction kettle, and quickly cool it to room temperature with tap water;

[0054] 2) Preparation of carbon nanofibers: Take 10 mL of the prepared tellurium nanowire solution, add 30 mL of acetone, and centrifuge at 8000 rpm for 45 min. The resulting precipitate was washed with a small amount of water to remove residual polyvinylpyrrolidone, and redispersed into 60 mL of ultrapure water. Add 3.0g of glucose and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com