High current-carrying capacity overhead insulation cable and manufacturing technology

An overhead insulated cable, high current carrying capacity technology, applied in insulated cables, power cables for overhead applications, power cables with shielding/conducting layers, etc., can solve the problem that the load cannot be effectively sent to the receiving end and the load channel. It can improve the tensile strength and elongation performance, reduce the occupation pressure, and improve the safety margin.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

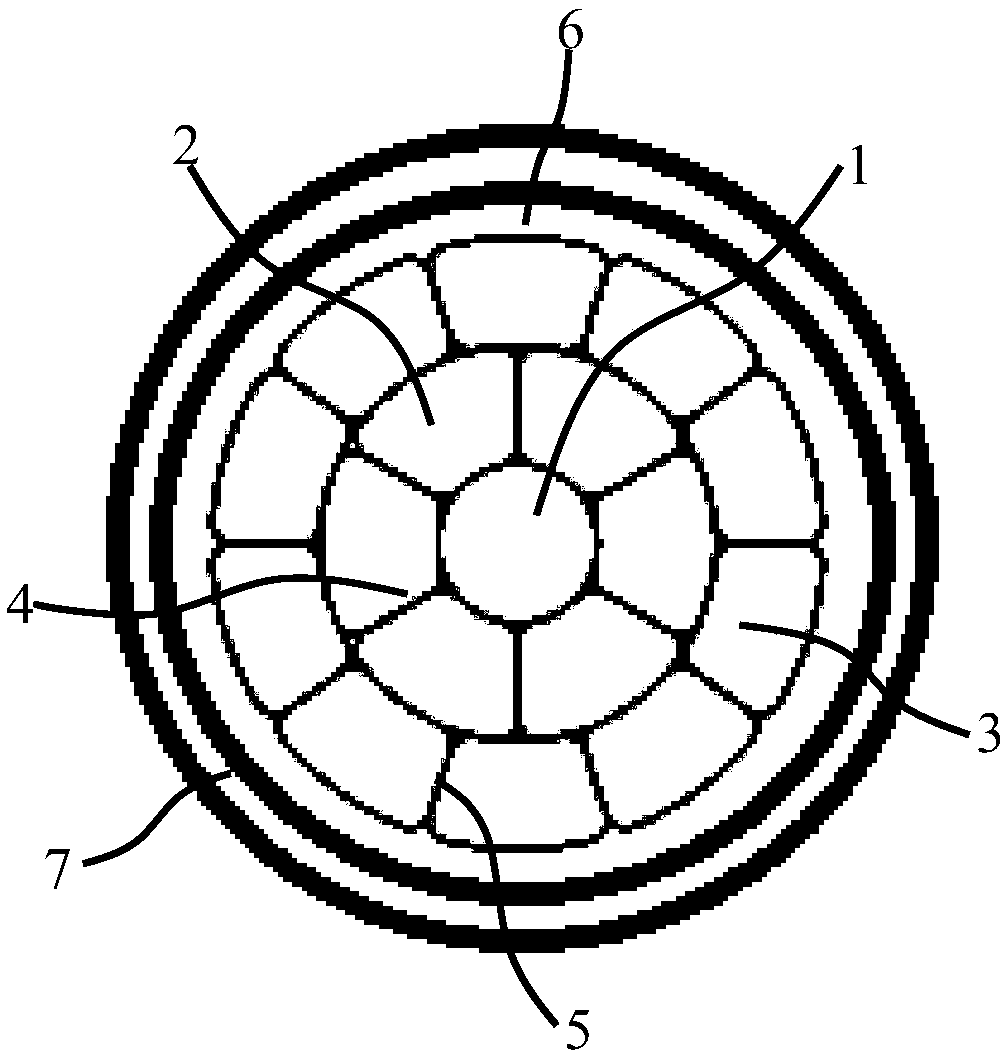

[0038] Embodiments 1 to 4: An overhead insulated cable with high ampacity, comprising: a circular aluminum conductor 1 with high conductivity, several first trapezoidal aluminum conductors 2 and several second trapezoidal aluminum conductors 3, the high conductivity The circular aluminum conductor 1 is located at the center, several first trapezoidal aluminum conductors 2 are twisted on the outer surface of the high-conductivity circular aluminum conductor 1 to form an inner conductive layer 4, and several second trapezoidal aluminum conductors 3 are twisted An outer conductive layer 5 is formed on the outer surface of the inner conductive layer 4, the height of the first trapezoidal aluminum conductor 2 is higher than the height of the second trapezoidal aluminum conductor 3; the outer conductive layer 5 is covered with a semiconductive shielding layer 6, Cross-linked polyethylene insulating layer 7;

[0039] The cross-linked polyethylene insulating layer 7 of the above-menti...

Embodiment 1

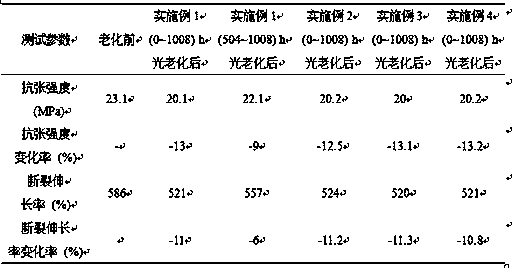

[0051] The properties of the cross-linked polyethylene insulating layer 7 in the overhead insulated cable in Example 1 are shown in Table 2 and Table 3:

[0052] Table 2 The performance change results of the test piece before and after photoaging

[0053]

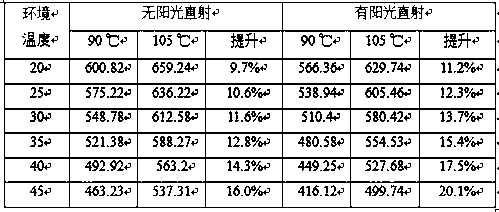

[0054] Table 3 Insulation mechanical properties before and after heat aging

[0055]

[0056] The aluminum rod is characterized in that it adopts a high-conductivity aluminum rod, and its conductivity is increased from 61% IACS of ordinary aluminum rods to 63% IACS. Reduce the loss during line transmission and improve the utilization rate of line power transmission.

[0057] The characteristics of the conductor are: the use of a profiled wire structure reduces the gap between monofilaments, increases the compression coefficient, and better balances the electric field. Compared with the ordinary map structure, under the condition of transmitting the same current, the outer diameter of the conductor of the structure i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com