Preparation method of anti-ultraviolet, anti-ageing and insect-prevention fiber

An anti-aging and anti-ultraviolet technology, applied in the chemical characteristics of fibers, rayon manufacturing, textiles and paper making, etc., can solve the problems of affecting the service life, aging, affecting the service life of outdoor products, etc., and achieve the effect of long-term insect control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

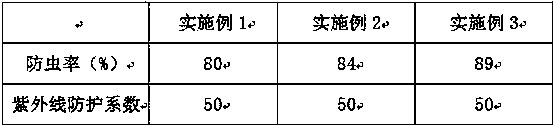

Examples

Embodiment 1

[0016] A method for preparing an anti-ultraviolet, anti-aging, and insect-resistant fiber. The preparation of an anti-ultraviolet, anti-aging, and insect-resistant fiber is completed through the preparation of a masterbatch, a spinning process, and a post-treatment process; the specific steps are as follows:

[0017] (1) Preparation of multifunctional spinning solution: uniformly mix functional compounding agent and hot-melt spinning chips, and heat to prepare blended spinning solution;

[0018] (2) Spinning process: Spin the melt blended spinning liquid into monofilament or multifilament through screw extruder;

[0019] (3) Post-treatment process: The formed anti-ultraviolet, anti-aging, anti-insect fiber is bundled, stretched, shaped, and wound to complete the post-treatment of the fiber, and the anti-ultraviolet, anti-aging, anti-insect filament fiber is obtained.

[0020] Functional materials include complexes formed by lanthanide metals and mono-organic compounds or compl...

Embodiment 2

[0023] A method for preparing an anti-ultraviolet, anti-aging, and insect-resistant fiber. The preparation of an anti-ultraviolet, anti-aging, and insect-resistant fiber is completed through the preparation of a masterbatch, a spinning process, and a post-treatment process; the specific steps are as follows:

[0024] (1) Preparation of multifunctional spinning solution: uniformly mix functional compounding agent and hot-melt spinning chips, and heat to prepare blended spinning solution;

[0025] (2) Spinning process: Spin the melt blended spinning liquid into monofilament or multifilament through screw extruder;

[0026] (3) Post-treatment process: The formed anti-ultraviolet, anti-aging, anti-insect fiber is bundled, stretched, shaped, and wound to complete the post-treatment of the fiber, and the anti-ultraviolet, anti-aging, anti-insect filament fiber is obtained.

[0027] The functional compounding agent includes complexes formed by lanthanide metals and mono-organic compo...

Embodiment 3

[0030] A method for preparing an anti-ultraviolet, anti-aging, and insect-resistant fiber. The preparation of an anti-ultraviolet, anti-aging, and insect-resistant fiber is completed through the preparation of a masterbatch, a spinning process, and a post-treatment process; the specific steps are as follows:

[0031] (1) Preparation of multifunctional spinning solution: uniformly mix functional compounding agent and hot-melt spinning chips, and heat to prepare blended spinning solution;

[0032] (2) Spinning process: Spin the melt blended spinning liquid into monofilament or multifilament through screw extruder;

[0033] (3) Post-treatment process: The formed anti-ultraviolet, anti-aging, anti-insect fiber is bundled, stretched, shaped, and wound to complete the post-treatment of the fiber, and the anti-ultraviolet, anti-aging, anti-insect filament fiber is obtained.

[0034] The functional compounding agent includes complexes formed by lanthanide metals and mono-organic compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com