Water-soluble 3D-printing supporting wax and preparation method thereof

A 3D printing, water-soluble technology, applied in the direction of additive processing, etc., can solve the problems of micro-dissolution of molding wax, flammability and explosion, and complicated post-processing, so as to improve the printing accuracy and casting accuracy, improve the balance of rigidity and toughness, and print fine-grained effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

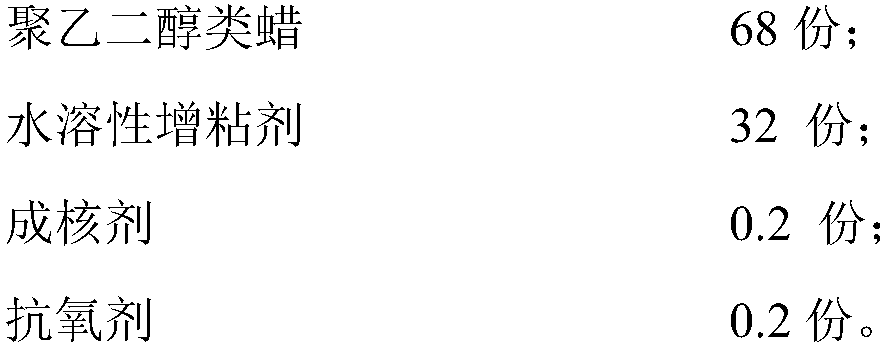

preparation example Construction

[0024] The present invention also provides a method for preparing the above-mentioned water-soluble 3D printing support wax, comprising the following steps:

[0025] Step 1: Weigh each component raw material according to the component distribution ratio, and mechanically mix each component;

[0026] Step 2: Heat and melt the uniformly mixed raw materials of each component at 70°C-200°C while stirring continuously to obtain a uniform dispersion;

[0027] Step 3: Filter the homogeneous dispersion at a constant temperature of 60°C-120°C to obtain a finished product, wherein the filter paper has a pore size of 0.1 μm-5 μm.

Embodiment 1

[0029] Step S11: Weigh the raw materials of each component according to 90Kg of polyethylene glycol wax, 50Kg of water-based rosin resin, 1Kg of stearate, and 0.5Kg of hindered phenolic antioxidant, and mechanically mix each component;

[0030] Step S12: heating and melting the homogeneously mixed raw materials of each component at 70° C. while stirring continuously to obtain a uniform dispersion;

[0031] Step S13: Filter the homogeneous dispersion at a constant temperature of 60° C. to obtain a finished product, wherein the pore size of the filter paper is 0.1 μm.

Embodiment 2

[0033] Step S21: Weigh the raw materials of each component according to 20Kg of polyoxyethylene (polyethylene glycol) wax, 5Kg of water-based acrylic resin, 0.1Kg of sorbitol, and 0.1Kg of hindered amine antioxidant, and mechanically mix each component;

[0034] Step S22: heating and melting the homogeneously mixed raw materials of each component at 200° C. while stirring continuously to obtain a uniform dispersion;

[0035] Step S23: Filter the homogeneous dispersion at a constant temperature of 120° C. to obtain a finished product, wherein the filter paper has a pore size of 5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com