Low-emissivity coated glass capable of enabling film surface to be tempered downwards

A low-radiation coating and glass technology, applied in the field of environmental protection and energy-saving building materials, can solve the problems of high production cost, insufficient film surface strength, and insufficient patch in time, and achieves the goal of reducing the energy consumption of tempering, improving the imaging effect, and reducing the time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

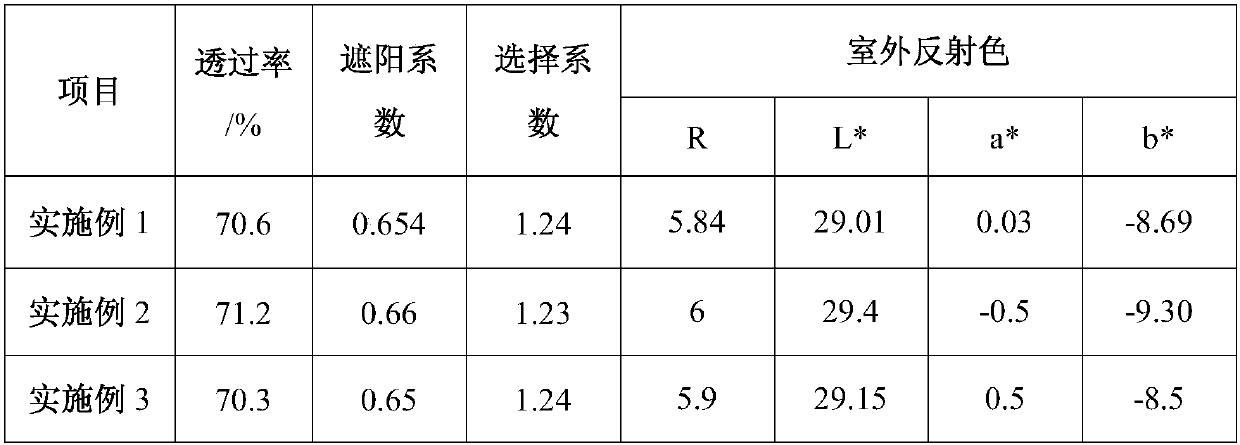

Embodiment 1

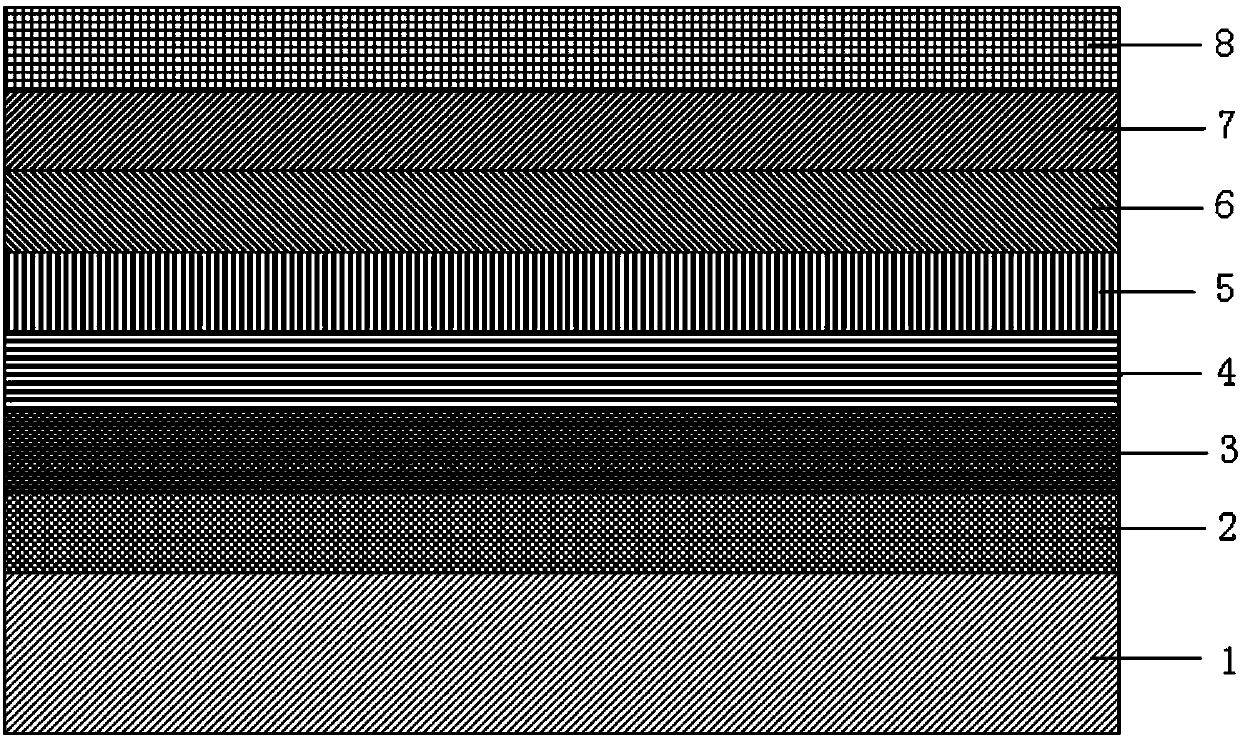

[0026] Using vacuum off-line magnetron sputtering coating equipment, on a 6mm high-quality float glass substrate, 12.5nm silicon nitride layer, 1nm nickel-chromium layer, 28nm zinc oxide tin layer, 5nm zinc oxide layer, 8nm Silver layer, 2nm nickel chromium layer, 44nm silicon nitride layer and 5nm graphite layer.

Embodiment 2

[0028] Using vacuum off-line magnetron sputtering coating equipment, on a 6mm high-quality float glass substrate, 14nm silicon nitride layer, 0.8nm nickel-chromium layer, 30nm zinc tin oxide layer, 5nm zinc oxide layer, 9nm Silver layer, 1.8nm nickel chromium layer, 46nm silicon nitride layer and 8nm graphite layer.

Embodiment 3

[0030] Using vacuum off-line magnetron sputtering coating equipment, on a 6mm high-quality float glass substrate, 13nm silicon nitride layer, 1.2nm nickel-chromium layer, 26nm zinc oxide layer, 7nm zinc oxide layer, 8.5 nm silver layer, 2.1nm nickel chromium layer, 43.5nm silicon nitride layer and 10nm graphite layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com