Hydrocarbon reforming catalyst with modified SBA-15 molecular sieve as well as preparation method and application of hydrocarbon reforming catalyst

A technology for reforming catalysts and molecular sieves, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., and can solve the problem of poor carbon deposition and sulfur resistance of catalysts, limited anti-coking ability, strong interaction, etc. problems, to achieve the effect of increasing effective reaction sites, easy operation, and uniform channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

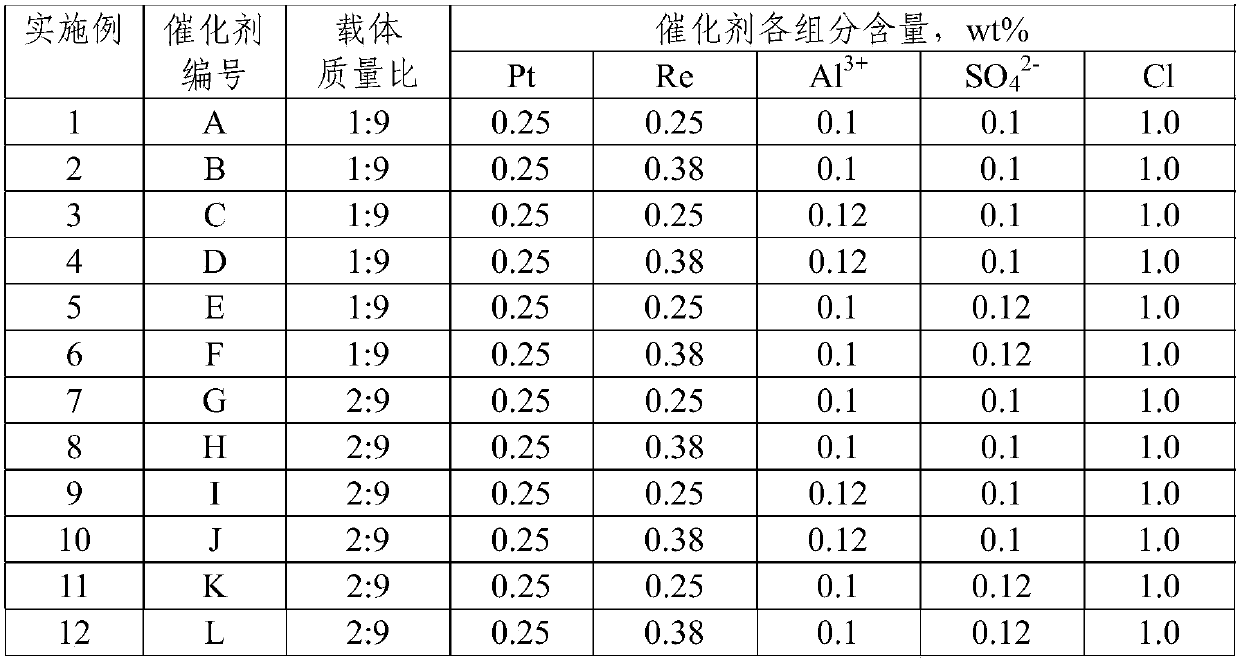

Examples

Embodiment 1

[0039] This embodiment provides a method for preparing a reforming catalyst, including:

[0040] (1) prepare the SBA-15 molecular sieve containing sulfate radical

[0041] Make a certain amount of aluminum sulfate and aluminum nitrate into the impregnating solution, and the Al in the impregnating solution 3+ Content: 1.0wt%, SO4 2- Content: 1.0wt% (relative to the mass of SBA-15 molecular sieve on a dry basis), impregnate SBA-15 molecular sieve with impregnation solution for 6 hours at room temperature, dry at 120°C for 8 hours, and roast at 500°C for 6 hours to prepare the SBA-15 molecular sieve carrier.

[0042] (2) Preparation of mixed carrier

[0043] The SBA-15 molecular sieve carrier prepared in step (1) and the alumina carrier were uniformly mixed according to the mass ratio of 1:9 to obtain a mixed catalyst carrier.

[0044] (3) Preparation of catalysts containing platinum group metals, VIIB metals and halogens

[0045] Use chloroplatinic acid, perrhenic acid and h...

Embodiment 2

[0047] This embodiment provides a method for preparing a reforming catalyst, including:

[0048] (1) prepare the SBA-15 molecular sieve containing sulfate radical

[0049] Make a certain amount of aluminum sulfate and aluminum nitrate into the impregnating solution, and the Al in the impregnating solution 3+ Content: 1.0wt%, SO4 2- Content: 1.0wt% (relative to the mass of SBA-15 molecular sieve on a dry basis), impregnate SBA-15 molecular sieve with impregnating solution for 6 hours at room temperature, dry at 120°C for 8 hours, and roast at 500°C for 6 hours to obtain a modified SBA-15 molecular sieve carrier.

[0050] (2) Preparation of mixed carrier

[0051] The modified SBA-15 molecular sieve carrier prepared in step (1) and the alumina carrier were uniformly mixed according to the mass ratio of 1:9 to obtain a mixed catalyst carrier.

[0052] (3) Preparation of catalysts containing platinum group metals, VIIB metals and halogens

[0053] Use chloroplatinic acid, perrh...

Embodiment 3

[0055] (1) prepare the SBA-15 molecular sieve containing sulfate radical

[0056] Make a certain amount of aluminum sulfate and aluminum nitrate into the impregnating solution, and the Al in the impregnating solution 3+ Content: 1.2wt%, SO4 2- Content: 1.0wt% (relative to the mass of SBA-15 molecular sieve on a dry basis), impregnate SBA-15 molecular sieve with impregnation solution for 6 hours at room temperature, dry at 120°C for 8 hours, and roast at 500°C for 6 hours to prepare the SBA-15 molecular sieve carrier.

[0057] (2) Preparation of mixed carrier

[0058] The SBA-15 molecular sieve carrier prepared in step (1) and the alumina carrier were uniformly mixed according to the mass ratio of 1:9 to obtain a mixed catalyst carrier.

[0059] (3) Preparation of catalysts containing platinum group metals, VIIB metals and halogens

[0060] Use chloroplatinic acid, perrhenic acid and hydrochloric acid to prepare an impregnation solution, which contains 0.25wt% platinum, 0.25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com