GaN-based vertical cavity surface emitting light source with tunable light emitting wavelength

A technology of vertical cavity surface emission and light-emitting wavelength, which is applied in the direction of lasers, phonon exciters, laser components, etc., can solve the problems of device processing technology and difficult practical application in the process of complex material growth, and achieve simplified process and device production Difficulty, effect of increasing tuning range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the process flow of the present invention will be further described in detail below in conjunction with the accompanying drawings.

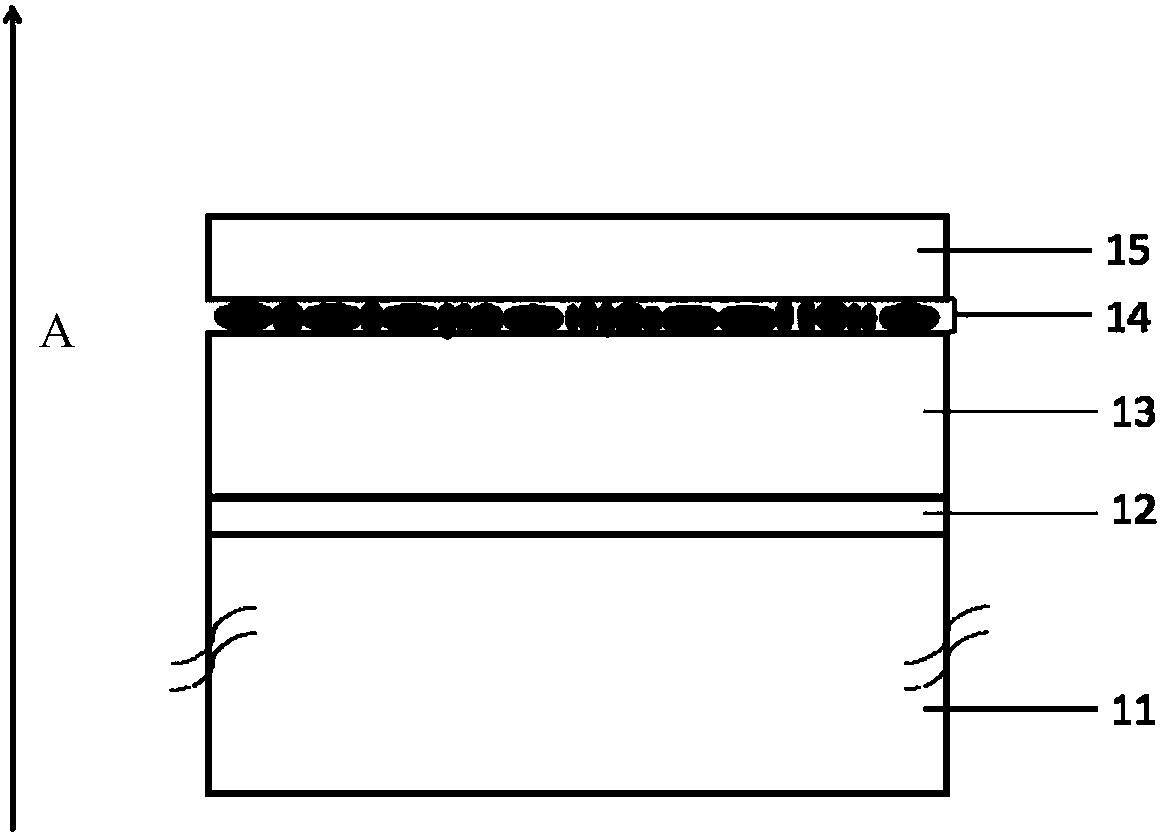

[0022] 1) if figure 1 As shown, the epitaxial layer with the quantum dot active region structure is grown on the sapphire substrate 11 by using the MOCVD method: the undoped u-GaN epitaxial layer 12, the n-type GaN epitaxial layer 13, and the SK mode growth InGaN / GaN Quantum dot active layer 14, p-type GaN epitaxial layer 15. InGaN quantum dots have different size distributions. exist figure 1 In , mark A is the material growth direction.

[0023] 2) to figure 1 The shown epitaxial wafer is used to make a tunable surface emitting light source device, and the cross-sectional structure of the device is shown in figure 2 shown. From bottom to top, the devices are: copper substrate 21 made by electroplating, lower dielectric film distributed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com