A self-protection DC contactor drive circuit

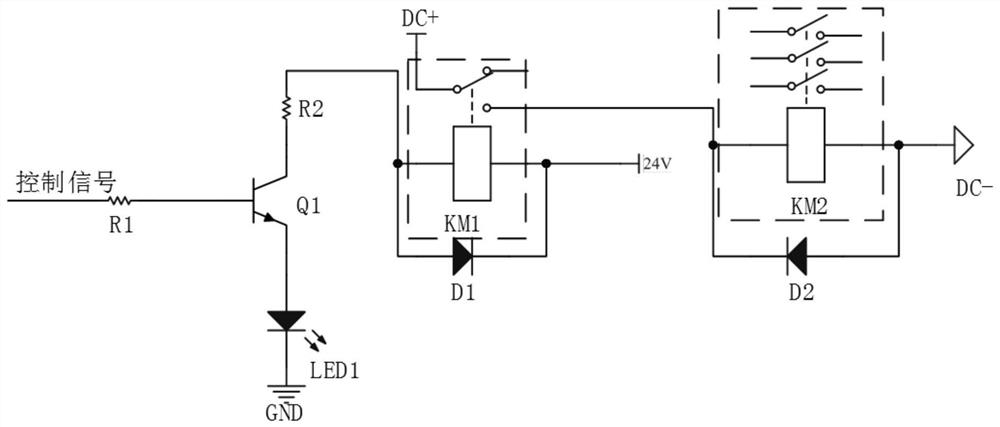

A DC contactor and drive circuit technology, applied in circuits, relays, electrical components, etc., can solve the problems of inconvenient inspection and maintenance, easy disconnection, easy failure, etc., to improve control performance and use safety performance, Extend service life and efficiency, and ensure stable and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

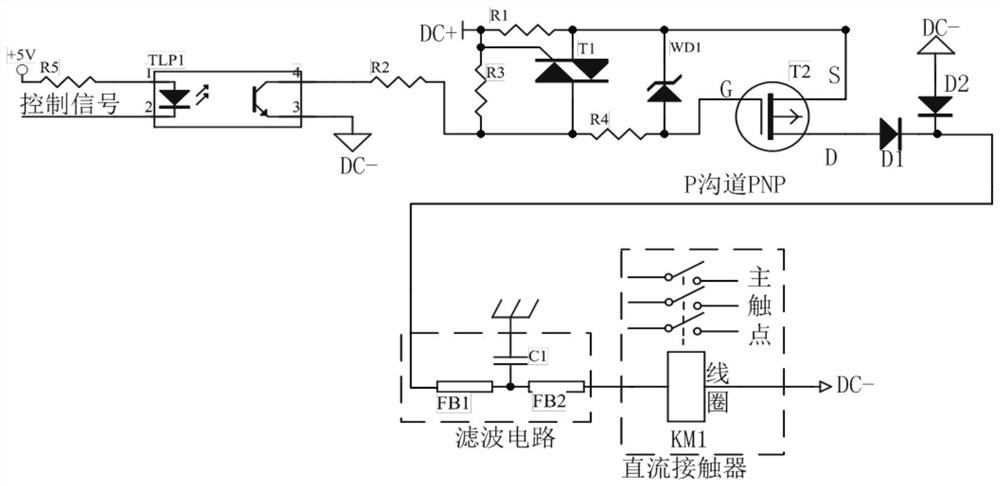

[0012] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0013] Such as figure 2 As shown, a self-protection DC contactor driving circuit includes an isolated optocoupler, a bidirectional thyristor, a voltage regulator tube, a MOSFET tube, an anti-reverse diode, a freewheeling diode and a filter circuit, a first resistor, a first voltage dividing resistor, The second voltage dividing resistor and the driving resistor, the first terminal pin of the isolated optocoupler is connected to the positive pole of the power supply through the fifth resistor, and the fourth terminal pin of the isolated optocoupler is connected to the second voltage dividing resistor through the first voltage dividing resistor. One end, one end of the bidirectional thyristor and one end of the drive resistor, the other end of the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com