High-temperature furnace control device and temperature control method

A technology for control devices and high-temperature furnaces, applied in the direction of furnace control devices, furnaces, furnace components, etc., can solve problems such as damage and deformation, and achieve the effects of avoiding expansion, reducing manual operations, and preventing overload current shocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

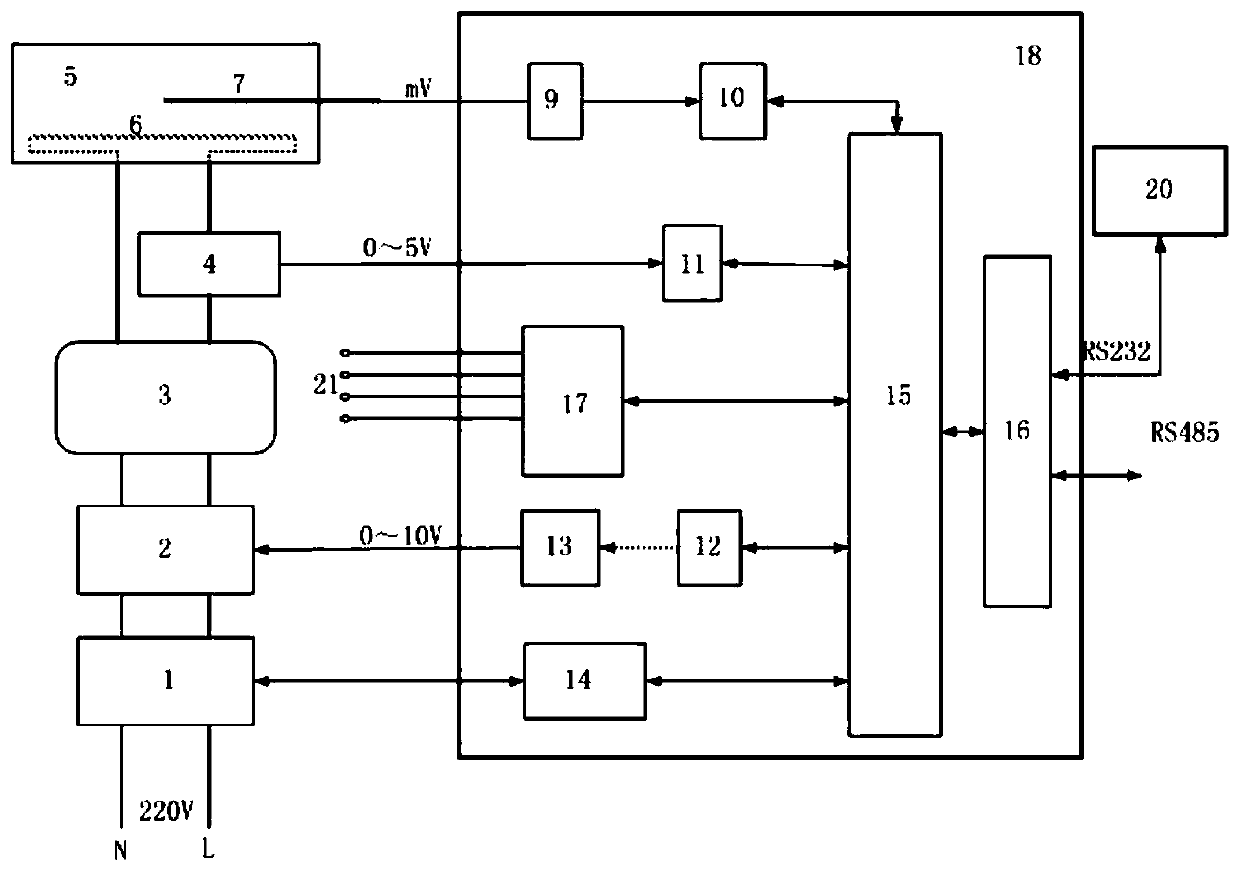

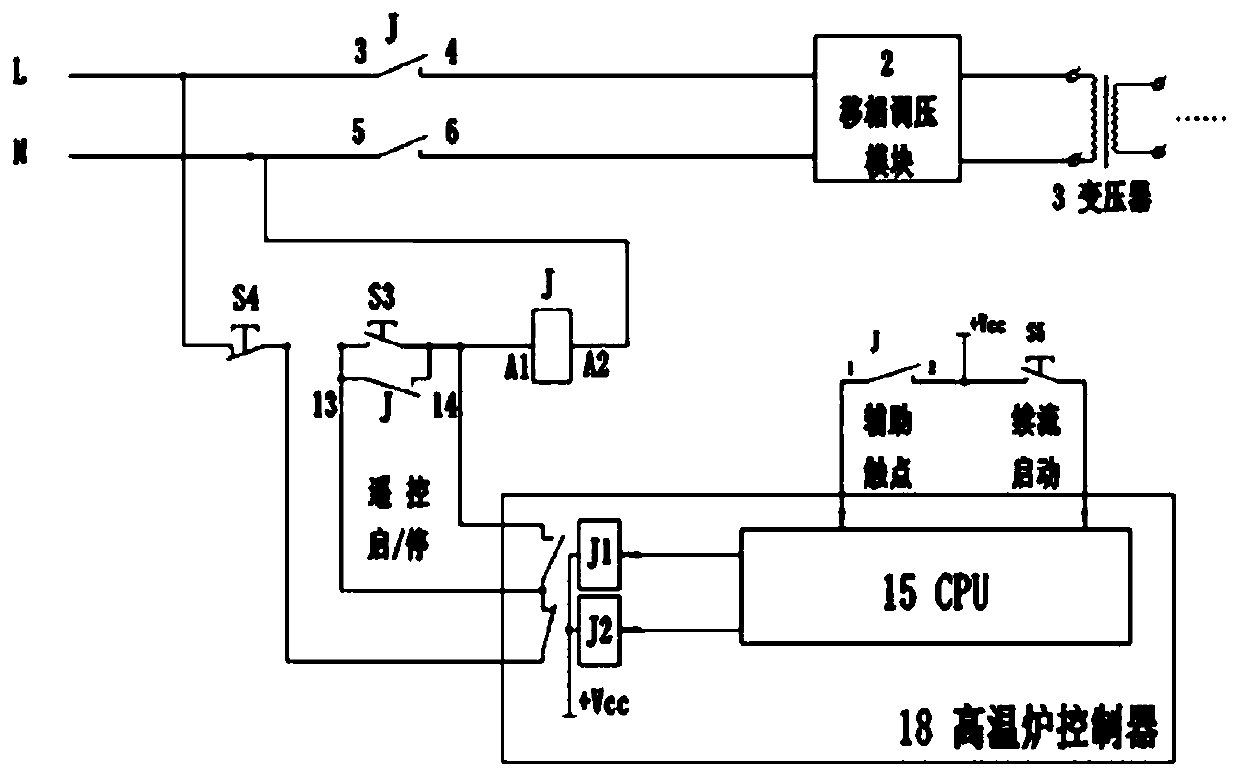

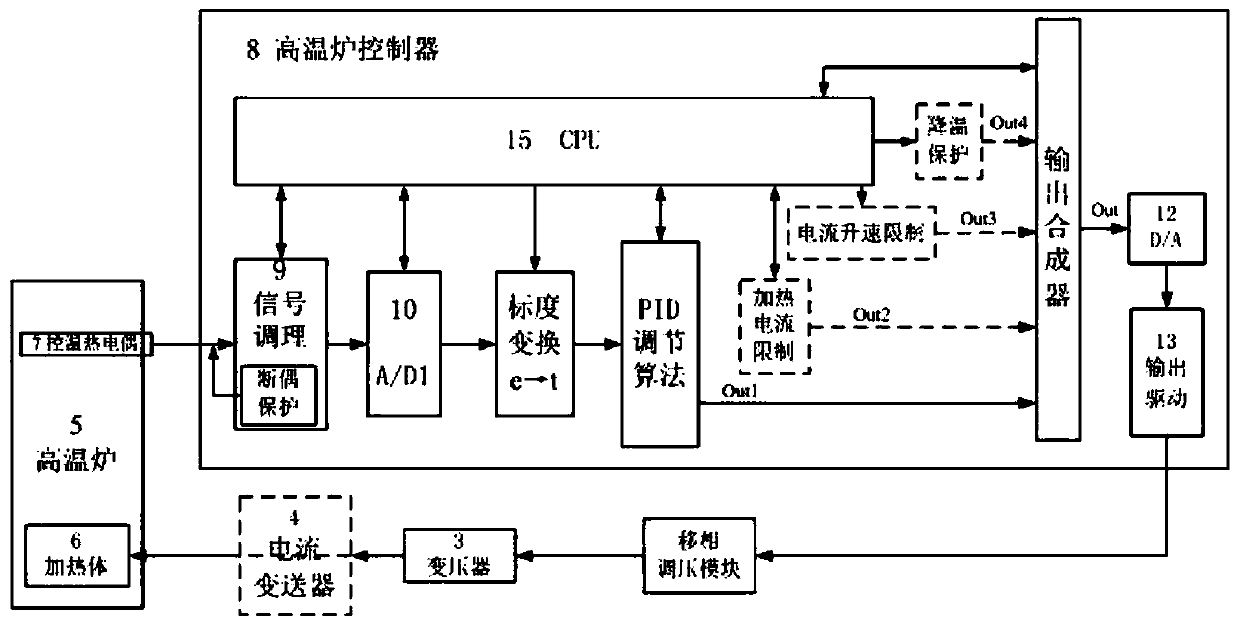

[0044] A kind of high temperature furnace control device see figure 1 , It includes start / stop self-locking circuit 1, phase-shift voltage regulating module 2, transformer 3, current transmitter 4, temperature control thermocouple 7, high temperature furnace controller 18, surface thermometer 19, touch screen console 20. The high temperature furnace controller includes a furnace temperature signal conditioning circuit 9, A / D1 10, A / D2 11, D / A 12, D / A output driver 13, start / stop control interface 14, CPU 15, communication interface 16, Temperature rise inspection interface 17. The temperature control thermocouple 7 is a type B thermocouple, the working end of which is placed in the effective working temperature zone of the high temperature furnace 5, the reference end is connected to the input end of the furnace temperature signal conditioning circuit 9 via an extension wire, and the current transmission The input end of the device 4 (that is, the toroidal core, through electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com