Multifunctional diatom ooze wall material

A diatom mud and multifunctional technology, applied in the field of building materials, can solve the problems of low porosity and poor adsorption, and achieve the effects of increasing porosity and specific surface area, increasing viscosity, and improving photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A multifunctional diatom mud wall material:

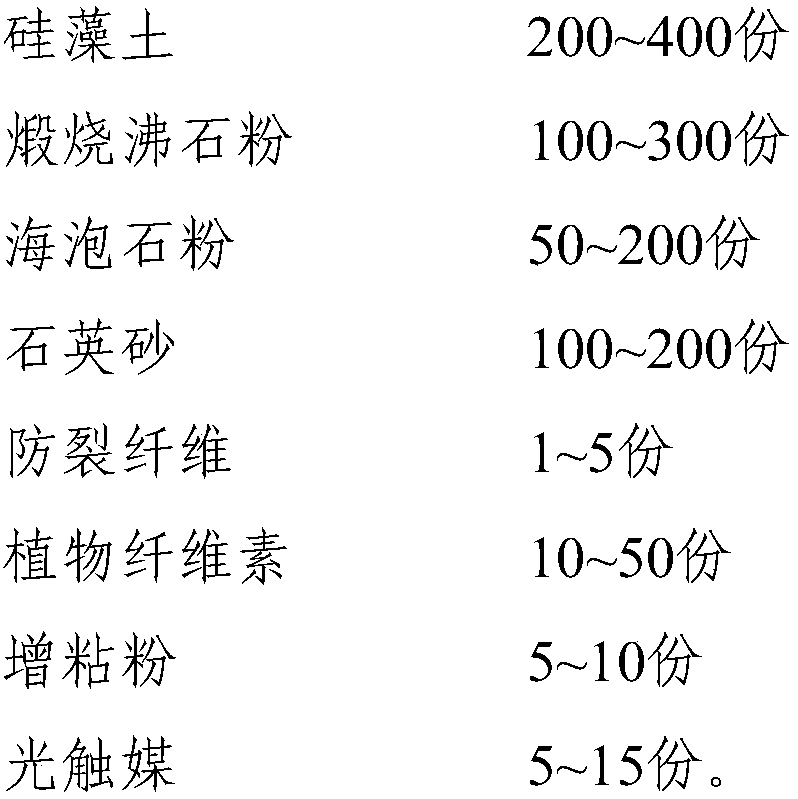

[0027] Formula: include the following components by weight:

[0028]

[0029] Preparation:

[0030] (1) Weigh 200 parts of diatomite, 100 parts of calcined zeolite powder, 50 parts of sepiolite powder, and 100 parts of quartz sand by weight, and add them to a 20% hydrochloric acid aqueous solution, stir and soak for 12 hours, and filter to obtain wet pink;

[0031] (2) After washing the wet powder obtained in step (1) with clear water, drying and grinding, the mixed powder is obtained;

[0032] (3) 1 part of polyester fiber, 10 parts of methyl cellulose, 5 parts of glutinous rice flour, 5 parts of mesoporous molecular sieve loaded titanium dioxide and zinc oxide are added to the mixed powder obtained in step (2) according to the proportioning by weight, and put Stir in a blender to combine evenly.

Embodiment 2

[0034] A multifunctional diatom mud wall material:

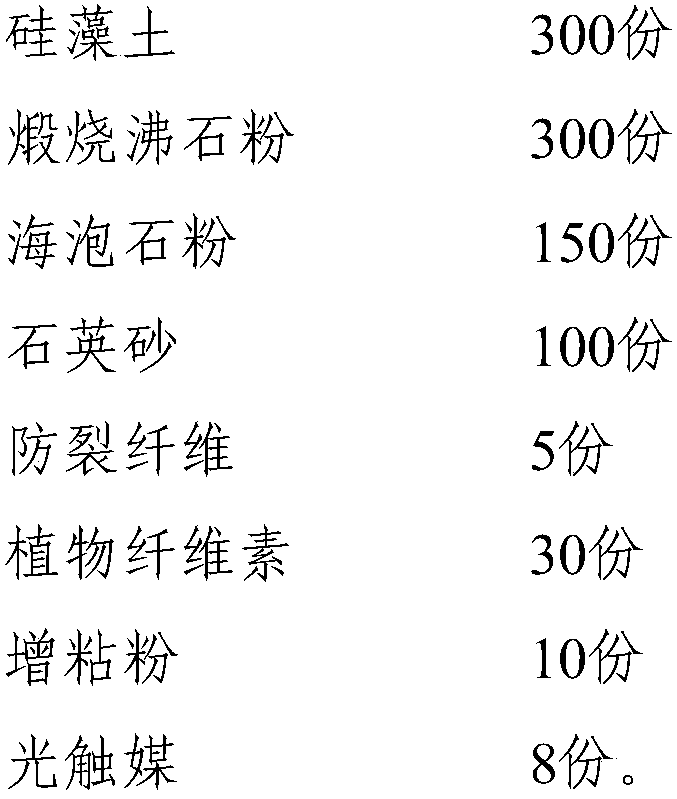

[0035] Formula: include the following components by weight:

[0036]

[0037] Preparation:

[0038] (1) Weigh 400 parts of diatomite, 300 parts of calcined zeolite powder, 200 parts of sepiolite powder, and 200 parts of quartz sand in parts by weight, add them into a 30% hydrochloric acid aqueous solution, stir and soak for 24 hours, and filter to obtain wet powder ;

[0039] (2) After washing the wet powder obtained in step (1) with clear water, drying and grinding, the mixed powder is obtained;

[0040] (3) 5 parts of polypropylene fibers, 50 parts of hydroxymethyl cellulose, 10 parts of glutinous rice flour, 15 parts of mesoporous molecular sieve loaded titanium dioxide and zinc oxide are added to the mixed powder obtained in step (2) according to the proportioning by weight, Put in a blender and mix well.

Embodiment 3

[0042] A multifunctional diatom mud wall material:

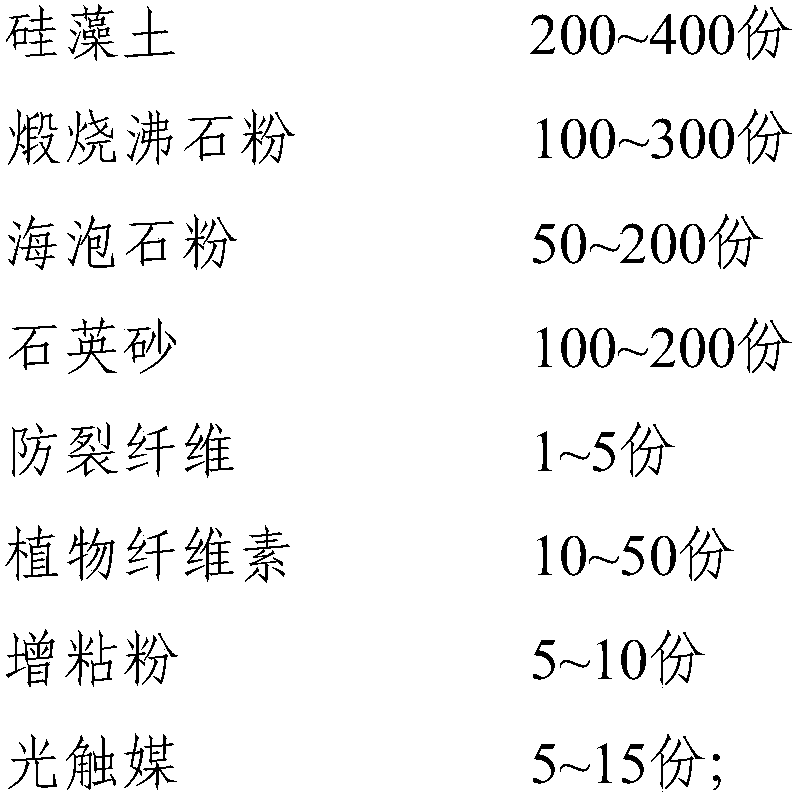

[0043] Formula: include the following components by weight:

[0044]

[0045]

[0046] Preparation:

[0047] (1) Weigh 300 parts of diatomite, 300 parts of calcined zeolite powder, 150 parts of sepiolite powder, and 100 parts of quartz sand by weight, add them into 25% nitric acid aqueous solution, stir and soak for 20 hours, and filter to obtain wet powder ;

[0048] (2) After washing the wet powder obtained in step (1) with clear water, drying and grinding, the mixed powder is obtained;

[0049] (3) 5 parts of polyester fibers, 30 parts of hydroxypropyl cellulose, 10 parts of glutinous rice flour, 8 parts of mesoporous molecular sieve loaded titanium dioxide and zinc oxide are added to the mixed powder obtained in step (2) according to the proportioning by weight, Put in a blender and mix well.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com