A lithium-sulfur battery with self-temperature control function

A lithium-sulfur battery and self-temperature control technology, which is applied to lithium batteries, secondary batteries, battery components, etc., can solve the problems of complex manufacturing process and high price, increase safety and service life, and improve utilization rate , to avoid the effect of discharge capacity drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Calcium chloride, strontium chloride, sodium chloride, acrylic acid, glycerol, hydroxyethyl methacrylate, maleic anhydride, sodium hydroxymethyl cellulose, and silicon dioxide are: 31%, 11.5% by mass , 6%, 3%, 5%, 4%, 3.5%, 2.5%, 33.5% mixed in proportion, put into water (mass solid content 30%), mix and stir at 60°C for 3h, let stand for 0.5h, vacuum at 65°C After drying, take 0.1g of the mixture and disperse it in 1.3g of N-methylpyrrolidone (NMP). After the dispersion is uniform, ultrasonication is performed for 20 minutes, stirred for 1 hour, and 0.132g of 10wt% polyvinylidene fluoride (PVDF) solution is added. The solvent is NMP. Stir for 5h, adjust the scraper to 200μm, and the coating amount is 1mg / cm 2 Scratch coating on a polypropylene film to form a film, dry overnight at 70°C, cut into small discs with a diameter of 19mm, and use it as a separator for a self-temperature-controlling battery. See figure 2 .

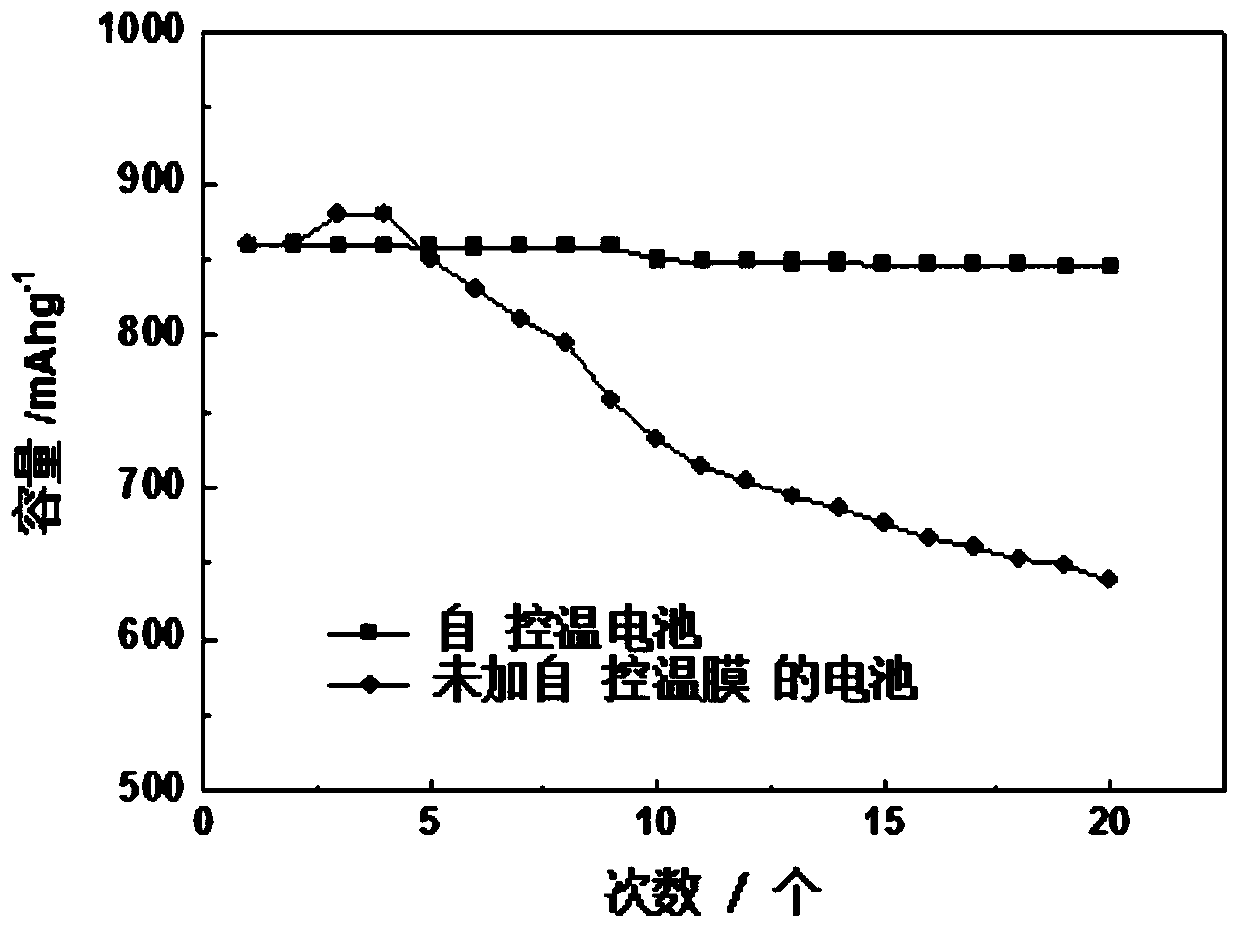

[0028] It can be seen from the results that unde...

Embodiment 2

[0030] Calcium chloride, strontium chloride, sodium chloride, acrylic acid, glycerol, hydroxyethyl methacrylate, maleic anhydride, sodium hydroxymethyl cellulose, and silicon dioxide are 30% and 11% by mass , 5%, 1%, 10%, 6%, 4%, 3%, 30% mixed in proportion, put into water (solid content 40%), mix and stir at 80°C for 3h, let stand for 0.5h, and vacuum dry at 65°C Finally, take 0.1g of the mixture and disperse it in 1.3g of N-methylpyrrolidone (NMP). After the dispersion is even, ultrasonicate for 20min, stir for 1h, add 0.132g of 10wt% polyvinylidene fluoride (PVDF) solution, the solvent is NMP, and stir for 5h , adjust the scraper to 1000μm, and the coating amount is 20mg / cm 2 Scratch coating on a polypropylene film to form a film, dry overnight at 70°C, and cut into small discs with a diameter of 19mm as a separator for a self-temperature-controlling battery.

Embodiment 3

[0032] Calcium chloride, strontium chloride, sodium chloride, acrylic acid, glycerol, hydroxyethyl methacrylate, maleic anhydride, sodium hydroxymethyl cellulose, and silicon dioxide are: 35%, 12% by mass , 7%, 5%, 10%, 2%, 3%, 2%, 24% mixed in proportion, put into water (solid content 15%), mix and stir at 45°C for 3h, let stand for 0.5h, and vacuum dry at 65°C Finally, take 0.1g of the mixture and disperse it in 1.3g of N-methylpyrrolidone (NMP). After the dispersion is even, ultrasonicate for 20min, stir for 1h, add 0.132g of 10wt% polyvinylidene fluoride (PVDF) solution, the solvent is NMP, and stir for 5h , adjust the scraper to 500μm, and the coating amount is 10mg / cm 2 Scratch coating on a polypropylene film to form a film, dry overnight at 70°C, and cut into small discs with a diameter of 19mm as a separator for a self-temperature-controlling battery.

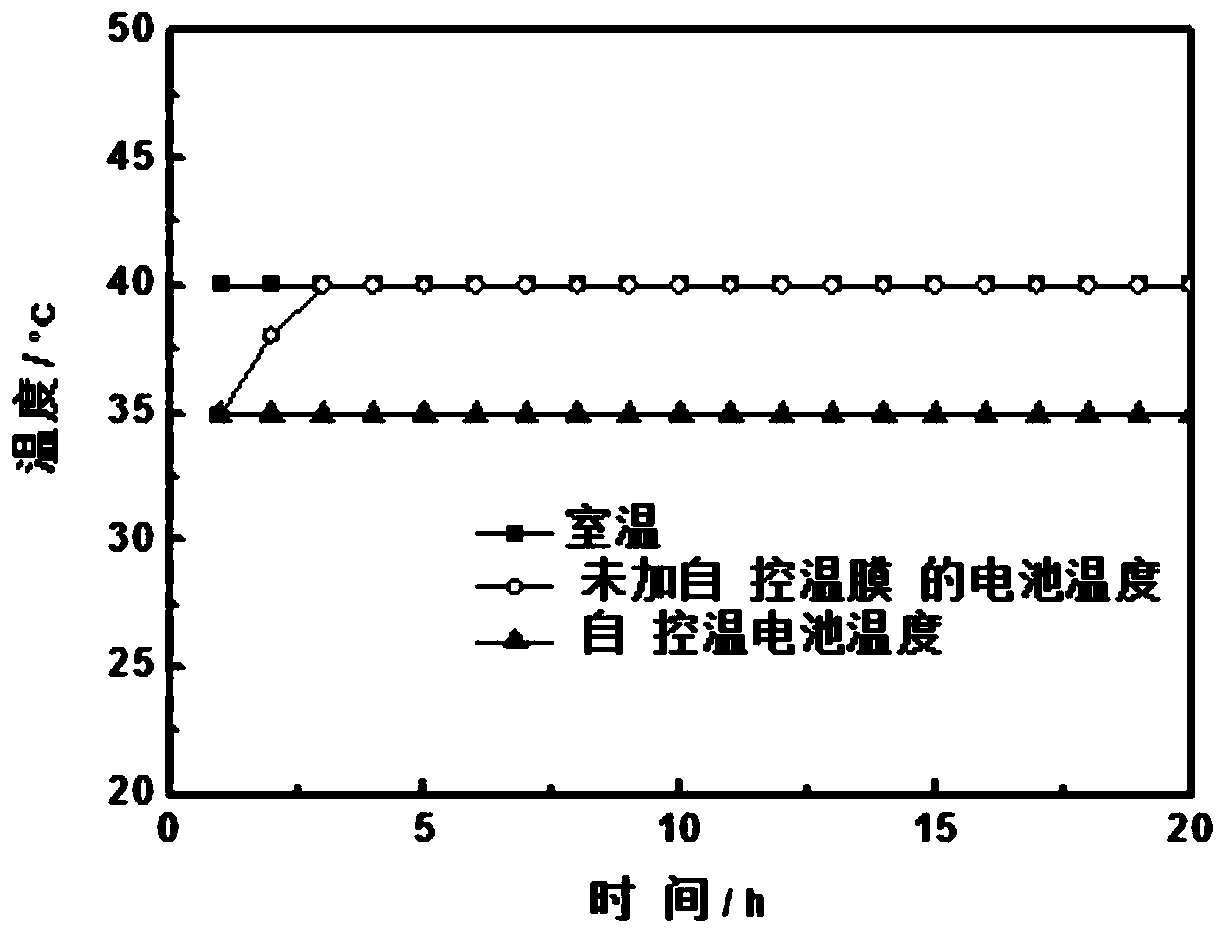

[0033] Depend on figure 1It can be seen from the results that when the ambient temperature is 40°C, the self-temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com