Carbon-doped sodium vanadium phosphate cathode material as well as preparation method and application thereof

A cathode material and a technology of sodium vanadium phosphate, which are applied in the field of carbon-doped sodium vanadium phosphate cathode materials and their preparation, can solve the problem that the rate performance of synthetic materials needs to be further improved, and achieve the effect of enhancing heat and mass transfer effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

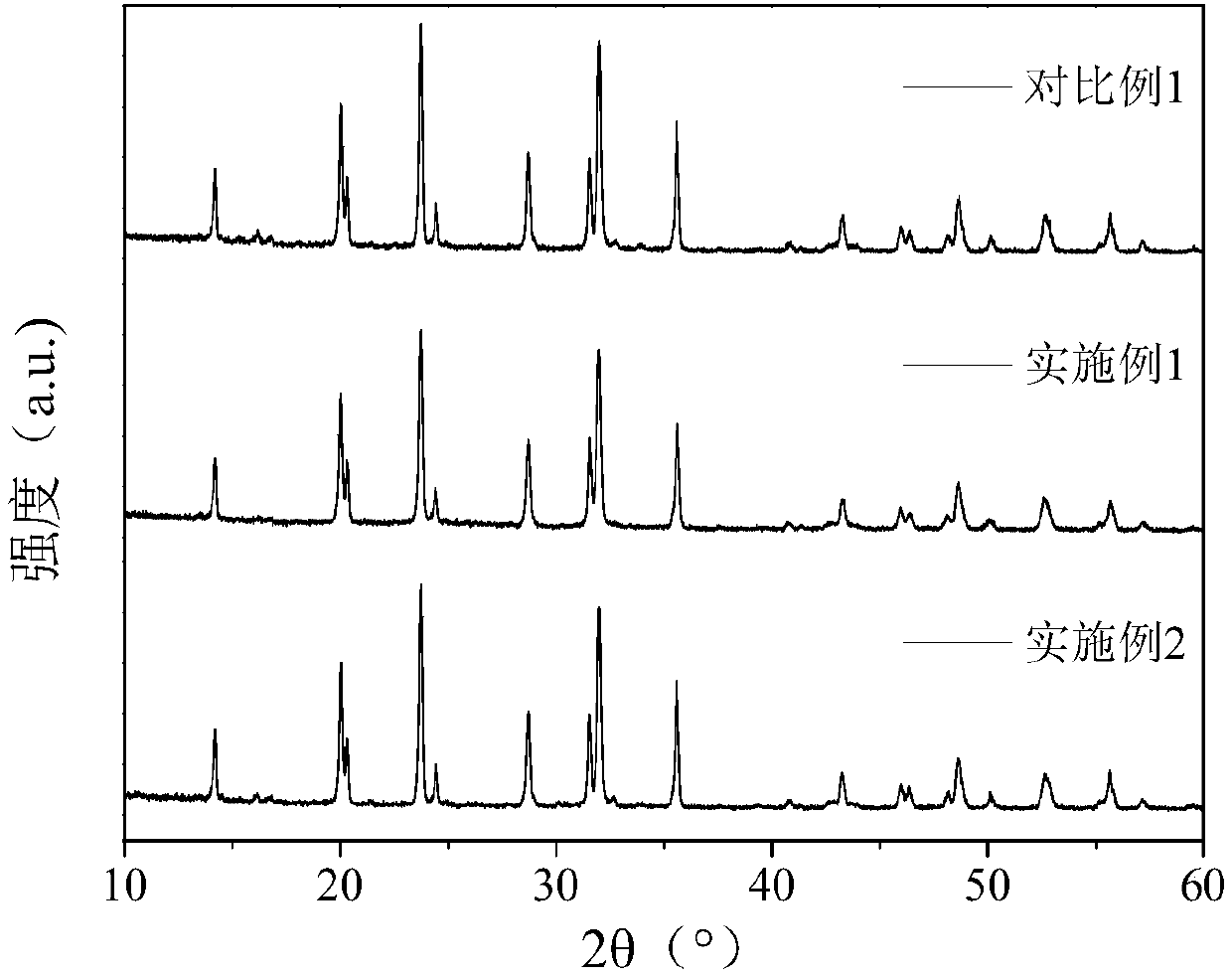

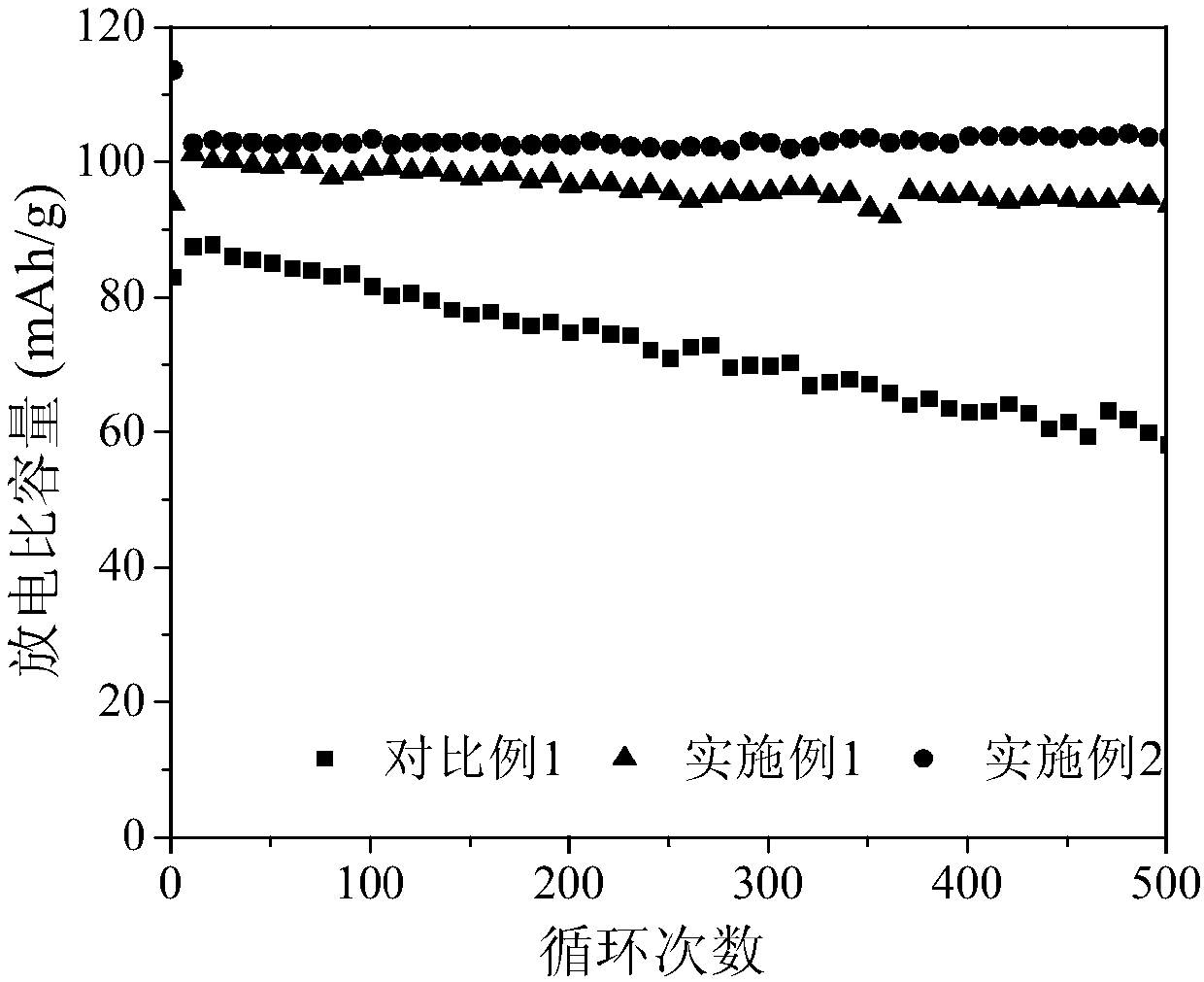

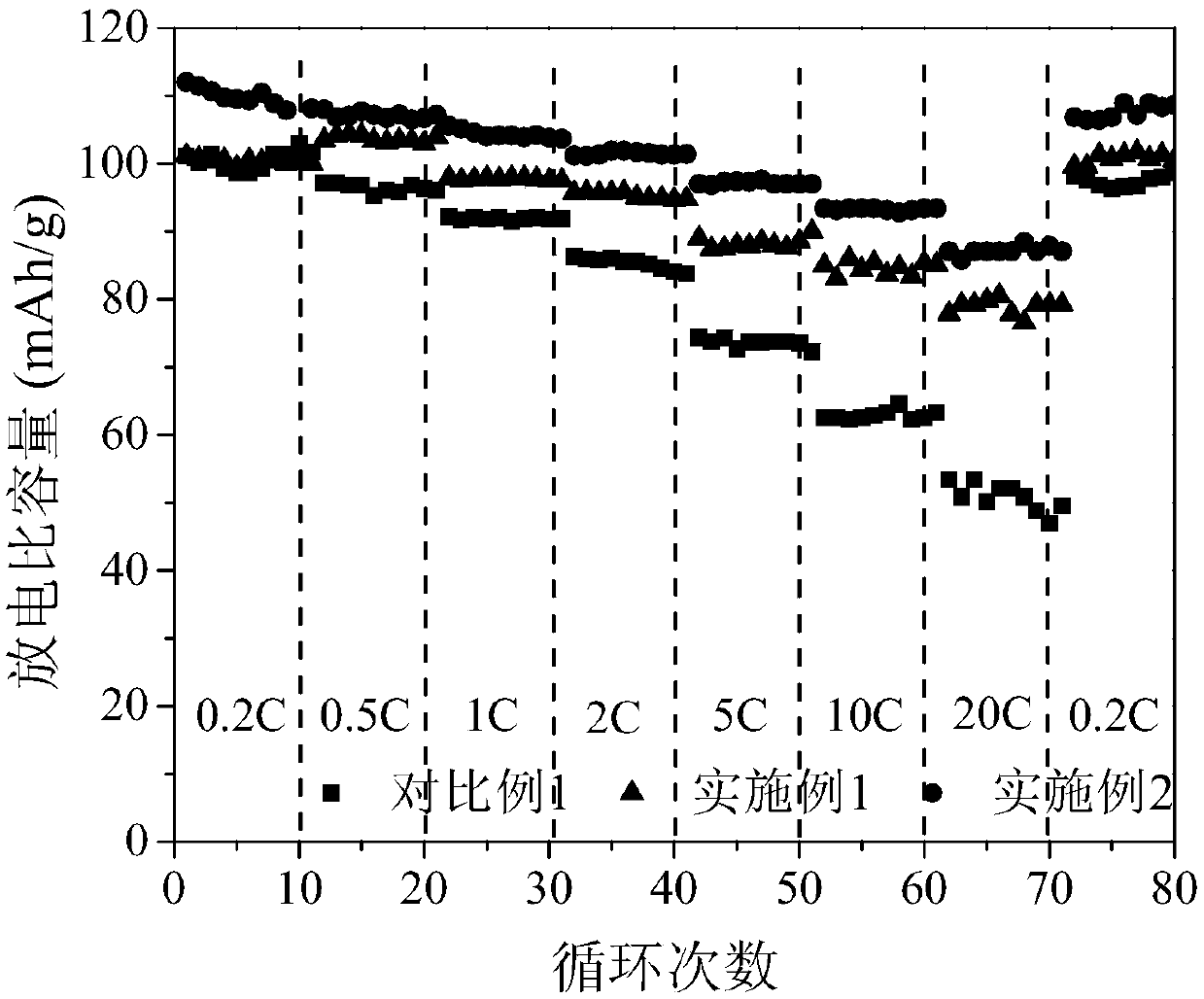

[0082] This embodiment provides a method for preparing a carbon-doped sodium vanadium phosphate cathode material, and the specific preparation method is as follows:

[0083] (1) Weigh 1.262g citric acid, 2.07g ammonium dihydrogen phosphate, 1.404g ammonium metavanadate, 0.72g sodium hydroxide (element ratio Na:V:P=3:2:3, Na:C=1: 2) Dissolve them in 80 mL of deionized water in sequence, and stir to obtain a solution;

[0084] (2) After heating and stirring the solution in a water bath at 80°C until a blue sol is formed, it is transferred to an oven at 80°C and dried to obtain a dry gel;

[0085] (3) The dry gel is fully ground and sieved with a 200-mesh sieve to obtain the precursor, and the precursor is transferred to a tube furnace. In a nitrogen atmosphere, the first stage calcination temperature is 350°C, and calcination is 3h , Then heat up to 800℃ for the second stage of calcination temperature, calcine for 8h, and naturally cool down to obtain Na 3 V 2 (PO 4 ) 3 / C product.

[...

Embodiment 2

[0095] This embodiment provides a method for preparing a carbon-doped sodium vanadium phosphate cathode material, and the specific preparation method is as follows:

[0096] (1) Weigh 1.262g citric acid, 2.07g ammonium dihydrogen phosphate, 1.404g ammonium metavanadate, 0.72g sodium hydroxide (element ratio Na:V:P=3:2:3, Na:C=1: 2) Dissolve them in 80 mL of deionized water in sequence, and stir to obtain a solution;

[0097] (2) After heating and stirring the solution in a water bath at 80°C until a blue sol is formed, it is transferred to an oven at 80°C and dried to obtain a dry gel;

[0098] (3) The dry gel is fully ground and sieved using a 200-mesh sieve to obtain a precursor. The precursor is transferred to a tube furnace. In a nitrogen atmosphere, a calcination temperature is 350°C for 3 hours. Raise the temperature to 800℃ for the second stage of calcination temperature, calcine for 8h, and naturally cool down to obtain Na 3 V 2 (PO 4 ) 3 / C product.

[0099] (4) Weigh 4.5428...

Embodiment 3

[0108] For the specific method of this embodiment, refer to Embodiment 1, the difference is:

[0109] In step (1), the added amount of citric acid is 1.893g (element ratio Na:C=1:3);

[0110] In step (2), the heating temperature of the water bath is 70°C, and the drying temperature is 70°C;

[0111] In step (3), the first stage calcination temperature is 400°C, the calcination time is 2h, the second stage calcination temperature is 780°C, and the calcination time is 7h;

[0112] In step (4), adjust the pH of the buffer solution to 8.3, add 0.15g of dopamine hydrochloride, and the concentration of dopamine hydrochloride in the solution is 2mg / mL;

[0113] In step (5), the calcination temperature in the first stage is 300°C for 4 hours, and the calcination temperature in the second stage is 780°C for 5 hours.

[0114] In the carbon-doped sodium vanadium phosphate cathode material obtained in this embodiment, Na composed of sodium vanadium phosphate and the first carbon layer 3 V 2 (PO 4 ) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com