Electromagnetic shielding composite paper and preparation method thereof

A technology of electromagnetic shielding and composite paper, which is applied in the fields of magnetic field/electric field shielding, special paper, synthetic cellulose/non-cellulose material pulp/paper, etc. It can solve the problem of paper conductivity, insufficient mechanical properties, limited preparation efficiency, and manufacturing cost Advanced problems, to achieve good electromagnetic shielding effectiveness, production cost control, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

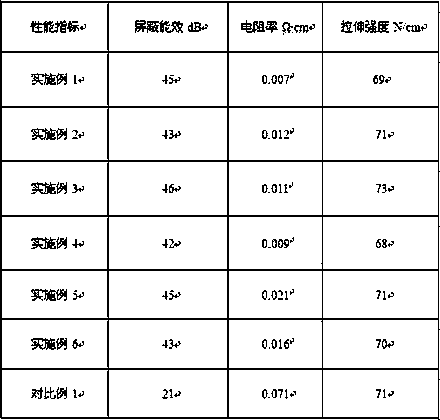

Examples

Embodiment 1

[0039] (1) in 10 -5Under the Pa vacuum environment, 5 parts by weight of high-purity nickel powder with a purity greater than 99% and a particle size of 20 nanometers are heated to 1540°C, the heating rate of the high-purity nickel powder is 120°C / min, and the temperature for maintaining the vacuum environment is 600°C. 50 wt. A single-walled carbon nanotube with a length of 10 nanometers. After the carbon nanotube is put in, turn off the vacuum system and wait for 2 hours. The carbon nanotube becomes the crystal nucleus of metallic nickel, and the nickel atoms gather on the surface of the carbon nanotube. The nickel atoms in the vacuum environment are aggregated and precipitated to obtain nickel-coated carbon nanotubes;

[0040] (2) Mix nickel-coated carbon nanotubes with 2.5 parts by weight of deionized water first, and stir to make the carbon nanotubes evenly dispersed in the process control agent, and then add 20 parts by weight of single-layer graphite powder to make the ...

Embodiment 2

[0044] (1) in 10 -4 Under the Pa vacuum environment, 15 parts by weight of high-purity nickel powder with a purity greater than 99% and a particle size of 50 nanometers is heated to 1820 ° C, the heating rate of the high-purity nickel powder is 80 ° C / min, the temperature of the vacuum environment is maintained at 460 ° C, and 50 wt. A mixture of double-walled carbon nanotubes and multi-walled carbon nanotubes with a length of 100 nanometers. After the carbon nanotubes are put in, turn off the vacuum system and wait for 1 hour. The carbon nanotubes become the crystal nucleus of metallic nickel, and the nickel atoms gather in the carbon nanotubes. On the surface of the tube, carbon nanotubes and nickel atoms in the vacuum environment aggregate and settle to obtain nickel-coated carbon nanotubes;

[0045] (2) First mix the nickel-coated carbon nanotubes with 1 part by weight of absolute ethanol, stir to make the carbon nanotubes evenly dispersed in the process control agent, a...

Embodiment 3

[0049] (1) in 10 -2 Under the Pa vacuum environment, 10 parts by weight of high-purity nickel powder with a purity greater than 99% and a particle size of 45 nanometers is heated to 1600°C, the heating rate of the high-purity nickel powder is 100°C / min, the temperature of the vacuum environment is maintained at 500°C, and 50 wt. Surface-activated carbon nanotubes with a length of 20 nanometers. After the carbon nanotubes are put in, turn off the vacuum system and wait for 1.2 hours. The carbon nanotubes become the crystal nucleus of metallic nickel, and the nickel atoms gather on the surface of the carbon nanotubes. Coagulate and settle with nickel atoms in a vacuum environment to obtain nickel-coated carbon nanotubes;

[0050] (2) Mix the nickel-coated carbon nanotubes with 1.5 parts by weight of sodium stearate, and stir to make the carbon nanotubes uniformly dispersed in the process control agent, and then add 15 parts by weight of multilayer graphene to make the graphene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com