Wood surface modification method

A wood surface and modification technology, applied in wood treatment, wood processing appliances, wood treatment details, etc., can solve the problems of small volume, low efficiency and large equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

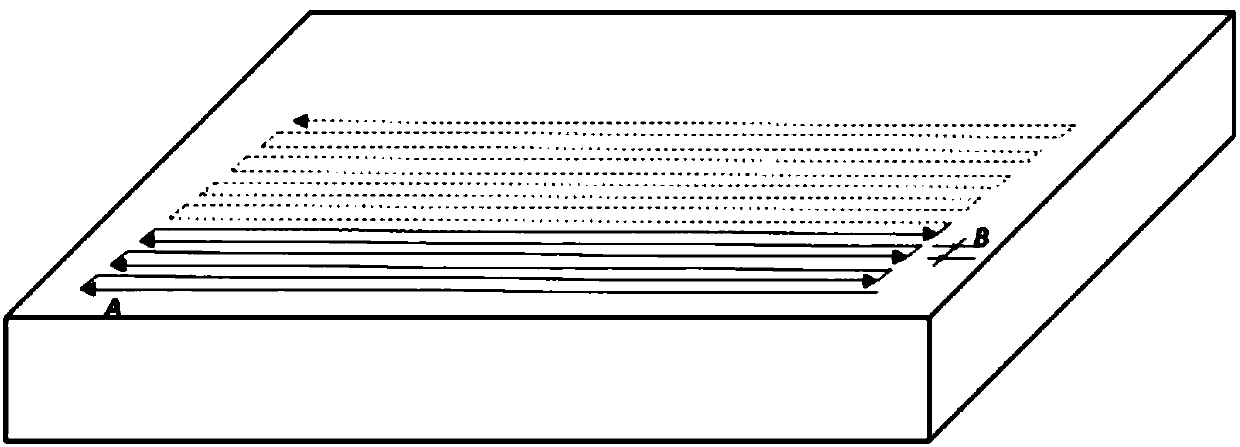

Image

Examples

Embodiment 1

[0030] Taking Poplar as an example to illustrate the specific steps:

[0031] (1) Set the modification target: set the total color difference of the modified wood (ΔE * ) is 30.0;

[0032] (2) Raw material color measurement: Utilize scanner to scan poplar wood surface, import image in Adobe Photoshop software, measure color parameter;

[0033] (3) Laser parameter setting: set the feed speed of the laser head to 150mm / s, the scanning width to 0.1mm, and the laser power to 13w;

[0034] (4) Modification effect evaluation: scan the poplar wood surface after modification, import the image into Adobe Photoshop software, measure the color parameters after modification, compare the difference between the total color difference of the color before and after modification and the target value 30, after The total color difference of poplar surface color after measurement is 29.98, the error is small, the modification effect is good, the color is uniform, the texture is clear, and the g...

Embodiment 2

[0036] Take eucalyptus as an example to illustrate the specific steps:

[0037] (1) Set the modification target: set the total color difference of the modified wood (ΔE * ) is 25.0;

[0038] (2) Raw material color measurement: use a scanner to scan the surface of eucalyptus wood, import the image into Adobe Photoshop software, and measure the color parameters;

[0039] (3) Laser parameter setting: set the feed speed of the laser head to 200mm / s, the scanning width to 0.2mm, and the laser power to 15w;

[0040] (4) Evaluation of modification effect: scan the surface of the modified eucalyptus, import the image into Adobe Photoshop software, measure the color parameters after modification, compare the difference between the total color difference of the color before and after modification and the target value of 25.0, and after The total color difference of poplar wood surface after measurement is 25.01, the error is small, the modification effect is good, the color is uniform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com