450MPa economical type high-surface-quality highly-reamed steel and preparation method thereof

A high reaming steel, 450mpa technology, applied in the field of 450MPa economical high surface quality high reaming steel and its preparation, can solve the problem of high cost, achieve the effect of reducing alloy cost, saving process cost and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention also provides a preparation method for the above-mentioned 450MPa-level economical high-surface-quality high-hole reaming steel, comprising the following steps: smelting process→continuous casting process→heating process→rough rolling process→hot coil box process→finish rolling process→laminar flow Cooling process → coiling → slow cooling → pickling process → coiling and packaging.

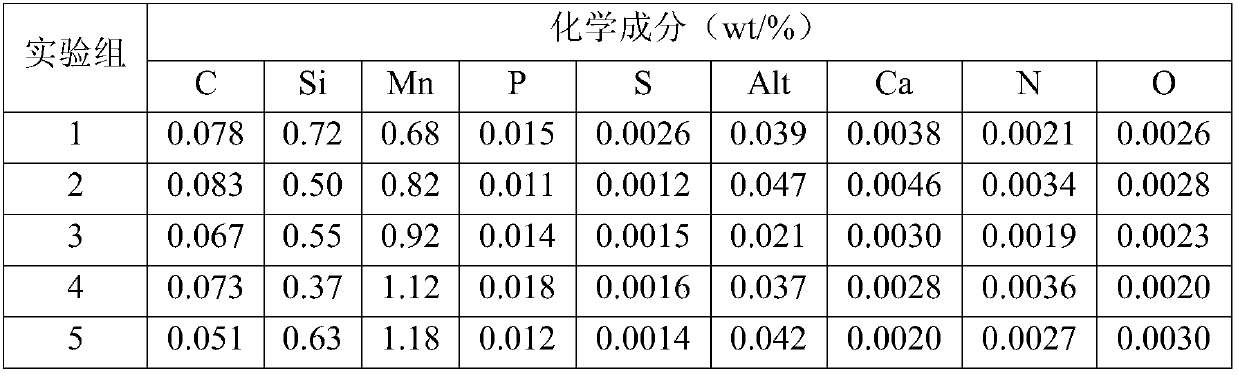

[0041] In the smelting process, smelting should be carried out according to the following chemical composition range, and the weight percentage of the chemical composition is as follows, [C]: 0.055~0.085%, [Si]: 0.30~0.80%, [Mn]: 0.60~1.30%, [P ]: 0.010~0.020%, [S]: ≤0.003%, [Alt]: 0.010~0.050%, [Ca]: 0.0010~0.0050%, [N]: ≤0.0050%, [O]: ≤0.0040%, the rest It is Fe and unavoidable impurities, and [C]×[Mn]×10 4 ≤0.10, {[P]+10×[S]}×10 2 ≤0.04, [Ca] / [S]≥0.3.

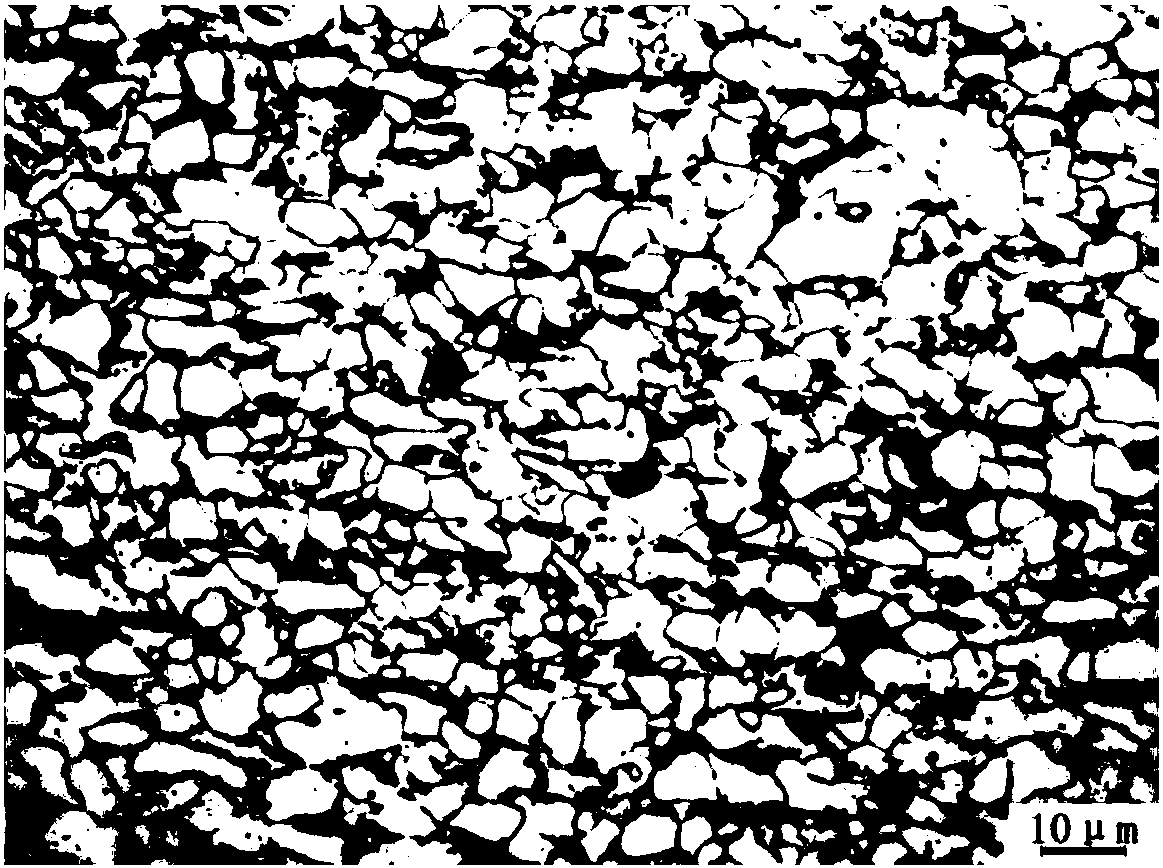

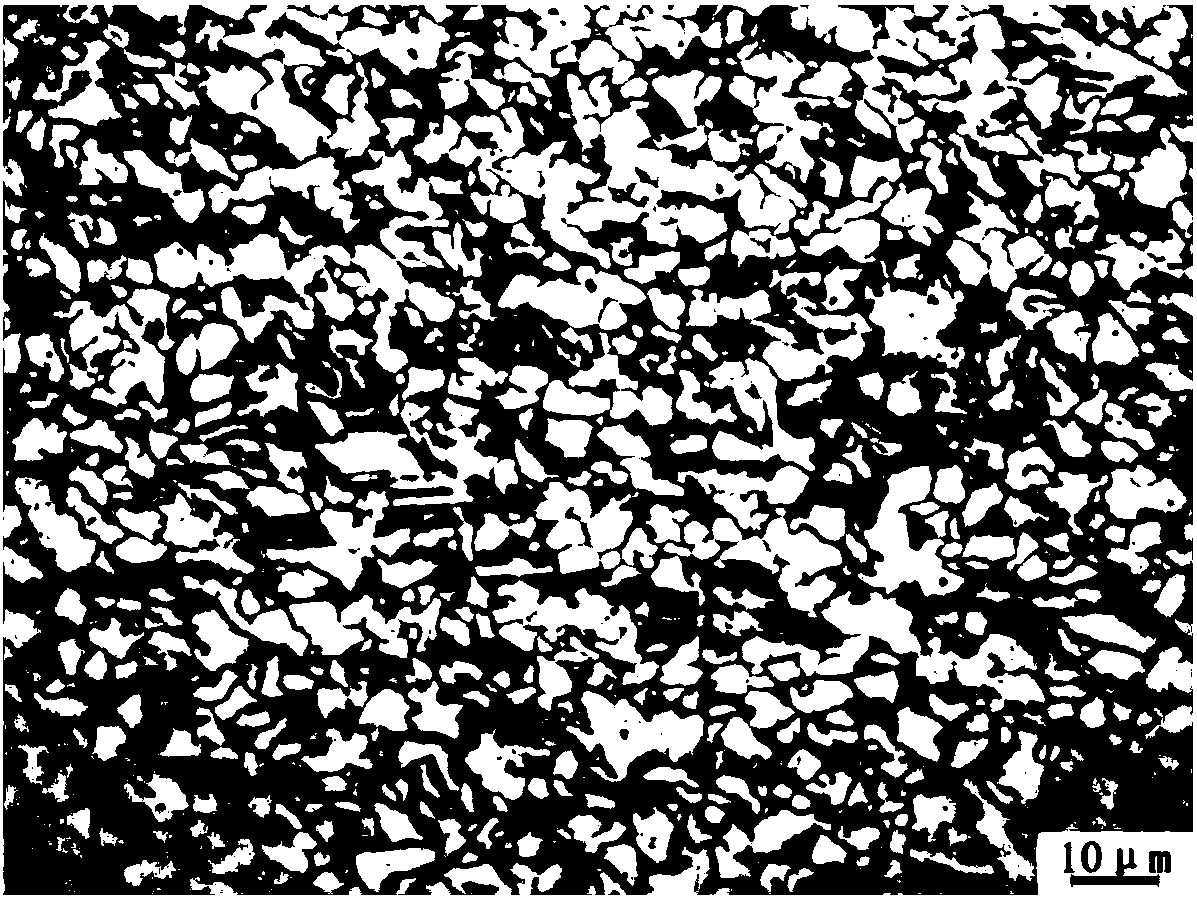

[0042] Aiming at the chemical composition of the 450MPa grade economical steel with high surface quality and hi...

Embodiment 1

[0058] This embodiment adopts six experimental groups, and the chemical composition of the 450MPa grade economical high surface quality and high hole reaming steel of experimental groups 1 to 6 is shown in Table 1;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com