Treatment process for high salinity organic wastewater produced during seafood processing process

A processing and treatment technology, applied in the field of organic wastewater treatment and high-salt organic wastewater treatment technology, can solve the problems of fluctuating treatment capacity, high salt content, difficulty in meeting needs, etc., and achieve stable operation and high treatment efficiency. high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

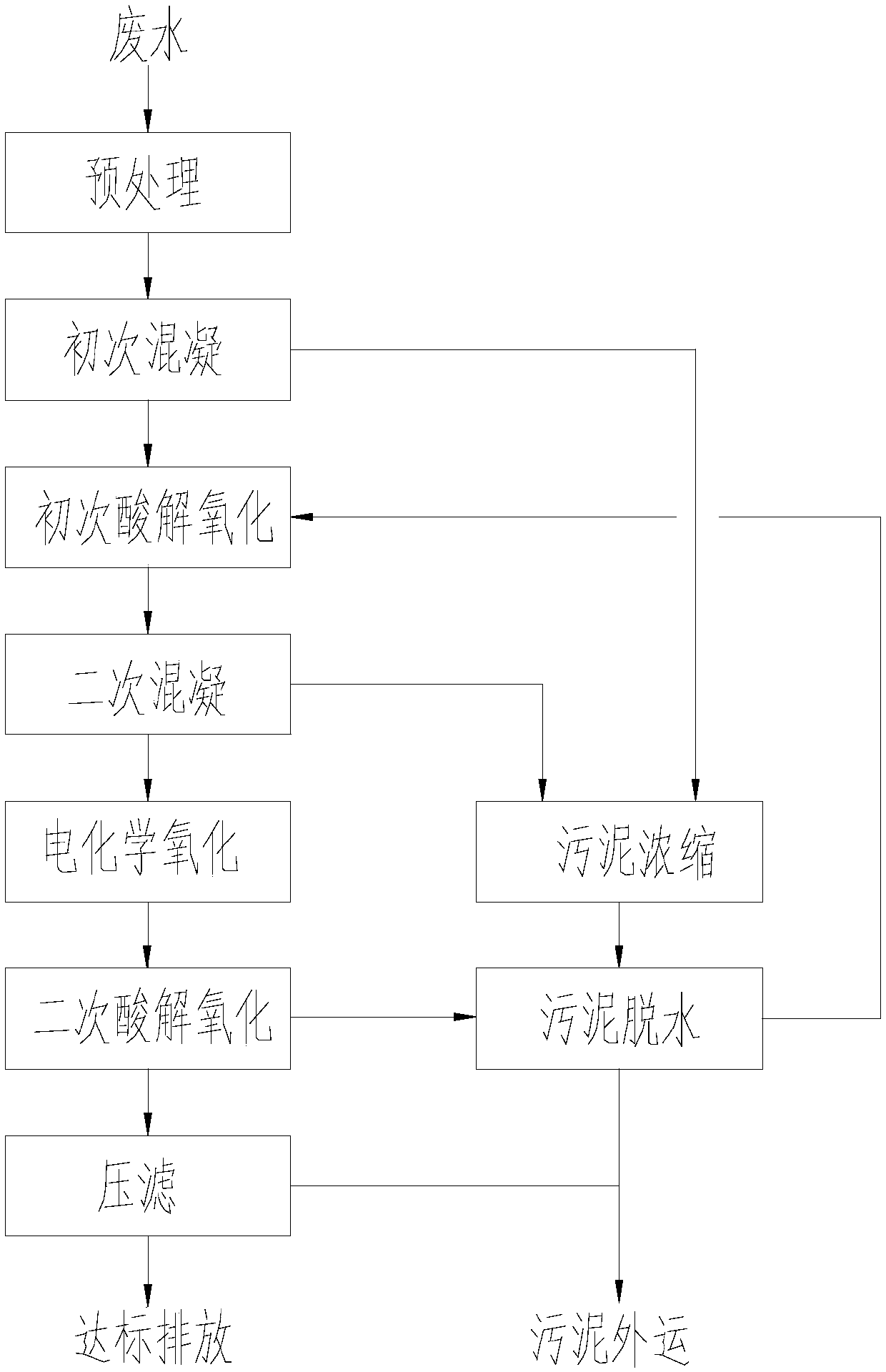

Image

Examples

Embodiment 1

[0024] 1) Pretreatment section: collect production wastewater and cleaning wastewater from an aquatic product processing enterprise in Shandong, enter the pretreatment section, and remove floating grease on the water body in the grease trap; 2) Primary coagulation section: in the primary sedimentation tank, Add the flocculant anionic polyacrylamide and the settling aid diatomaceous earth in turn, start stirring, the water purification material produces a large amount of flocs to sweep and settle the suspended solids in the water, and the settled sludge is pumped to the sludge thickening tank; 3) Primary acidolysis and oxidation section: the water after the first flocculation is put into the primary acidolysis and oxidation tank, 10% dilute sulfuric acid is added to adjust the pH value to 2.0, and then ferrous sulfate and hydrogen peroxide are added. Fe in the water 2+ Ion concentration is controlled at 0.5g / L, the amount of 30% hydrogen peroxide is 15ml / L, after 2.5 hours of reac...

Embodiment 2

[0034] 1) Pretreatment section: collect production wastewater and cleaning wastewater from an aquatic product processing enterprise in Shandong, enter the pretreatment section, and remove floating grease on the water body in the grease trap; 2) Primary coagulation section: in the primary sedimentation tank, Add flocculant anionic polyacrylamide, polyaluminum chloride and settling aid diatomaceous earth in sequence, turn on the stirring, the water purification material produces a large amount of flocs to sweep and settle the suspended matter in the water, and the settled sludge is pumped to Sludge thickening tank; 3) Primary acidolysis oxidation section: the water after the first flocculation is put into the primary acidolysis oxidation tank, 10% dilute sulfuric acid is added to adjust the pH to 3.5, and then ferrous sulfate and hydrogen peroxide are added. Fe in the water 2+ Ion concentration is controlled at 0.8g / L, the amount of 30% hydrogen peroxide is 15ml / L, after 2 hours of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com