Fiber pipe for breast implant

A technology of implants and fiber tubes, applied in the field of fiber tubes, can solve the problems of high incidence of capsular contracture, easy mold formation in saline capsules, poor shape and feel, etc., achieve no toxic side effects, avoid human tissue rejection and Effects on attack, good feel and form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

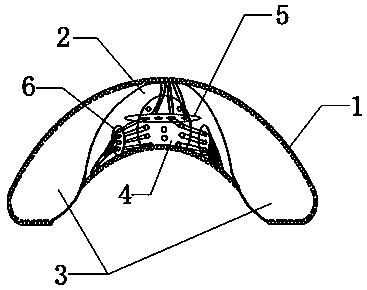

[0031] Such as figure 1 As shown, a breast implant includes an outer shell 1, the outer shell 1 is a hollow cavity, the outer contour of the outer shell 1 is in the shape of a human breast, the bottom of the outer shell 1 is sunken inward, and the inner middle of the outer shell 1 is provided with a growth Zone 2 is inside the outer casing 1 and a filling zone 3 is provided on both sides of the growth zone 2 . The top of the growth zone 2 is connected to the top of the outer casing 1, and the growth zone 2 is provided with a number of fixed pieces and a number of fiber tubes. The surface of the fixed pieces is evenly distributed with a number of through holes, and the fiber tubes pass through the through holes to connect the fixed pieces. The fixed piece includes a main piece 4, which is arranged in the middle of the growth area 2 along the vertical direction, and the surface of the main piece 4 is evenly distributed with three rows of through holes; the two sides of the main ...

Embodiment 2

[0034] polyether Synthesized by:

[0035] Add 69.5g (0.2mol) of hexachlorocyclotriphosphazene and 200mL of tetrahydrofuran into a four-neck flask equipped with mechanical stirring, reflux condenser, thermometer, and dropping funnel at room temperature, stir until all the solids are completely dissolved, and then add the solution dropwise. There is 69.7g of sodium phenolate in tetrahydrofuran; after the dropwise addition, reflux for 3 hours, filter and collect the filtrate; take another four-necked bottle, add 146.5g of p-hydroxybenzaldehyde, 300mL of tetrahydrofuran and 414.6g of anhydrous potassium carbonate in sequence, stir After p-Hydroxybenzaldehyde is completely dissolved, add the filtrate obtained above dropwise to it, reflux for 6 hours after the dropwise addition is completed, filter after the reaction is completed, collect the filtrate and concentrate it to 1 / 4 of the original volume; then, slowly put the remaining mixture into Stir rapidly in ice water until all the...

Embodiment 3

[0037] Modified silica gel Synthesized by:

[0038] Add 20 g of silica gel into concentrated hydrochloric acid, heat to reflux for 6 hours, wash with deionized water until neutral, and dry at 180° C. for 16 hours to obtain activated silica gel. Add 8g of activated silica gel to 80mL of dry toluene solvent, slowly add 8mL of 3-chloropropyltriethoxysilane dropwise, under the protection of nitrogen, reflux for 12h, filter, and the product is washed with toluene, ethanol and ether several times Wash and dry in vacuum at 80°C for 6h. Add 6g of thiosemicarbazide into 100mL of ethanol, heat to dissolve, add 8g of the above product, reflux for 8h, filter, wash with ethanol and hot water several times, and vacuum dry at 80°C for 12h to obtain the target product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com