Novel full-automatic edible mushroom bagging machine

A bacteria bagging machine, a fully automatic technology, applied in the field of automatic bagging machines, can solve the problems of difficult quality assurance, complex settings, high labor intensity, etc., to meet diverse needs, convenient and fast operation, and full automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

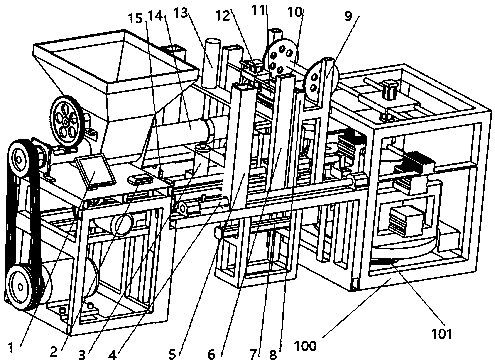

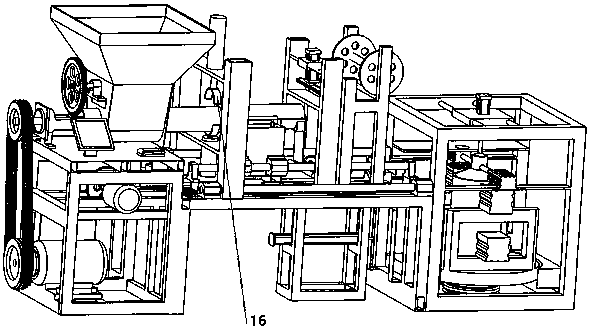

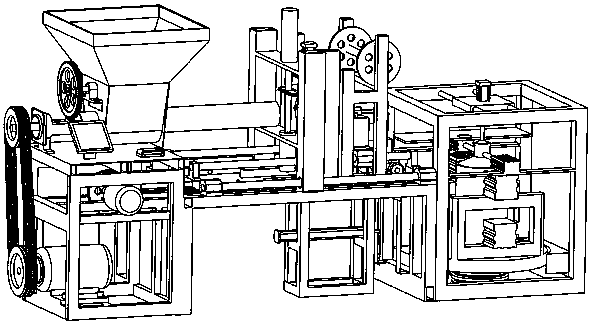

[0031] The following is attached figure 1 , 2, 3, 4, 5, 6, 7 describe in detail the specific embodiments of the present invention.

[0032] figure 1 It is a general structure diagram of a novel fully automatic edible mushroom bagging machine of the present invention, figure 2 It is a general drawing of a novel fully automatic edible fungus bagging machine of the present invention, where the bagging frame is left in place, image 3 It is a general drawing of a new type of full-automatic edible mushroom bagging machine of the present invention where the bagging rack is in place, the touch screen 1 is provided with a control panel, which can independently control the start and stop of the sealing device and the start and stop of the sealing device, and can also control the start and stop of the entire equipment. stop; the device is provided with a plurality of sensors 15 for detecting the operating status of the overall device, and the corresponding parameters can be displaye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com