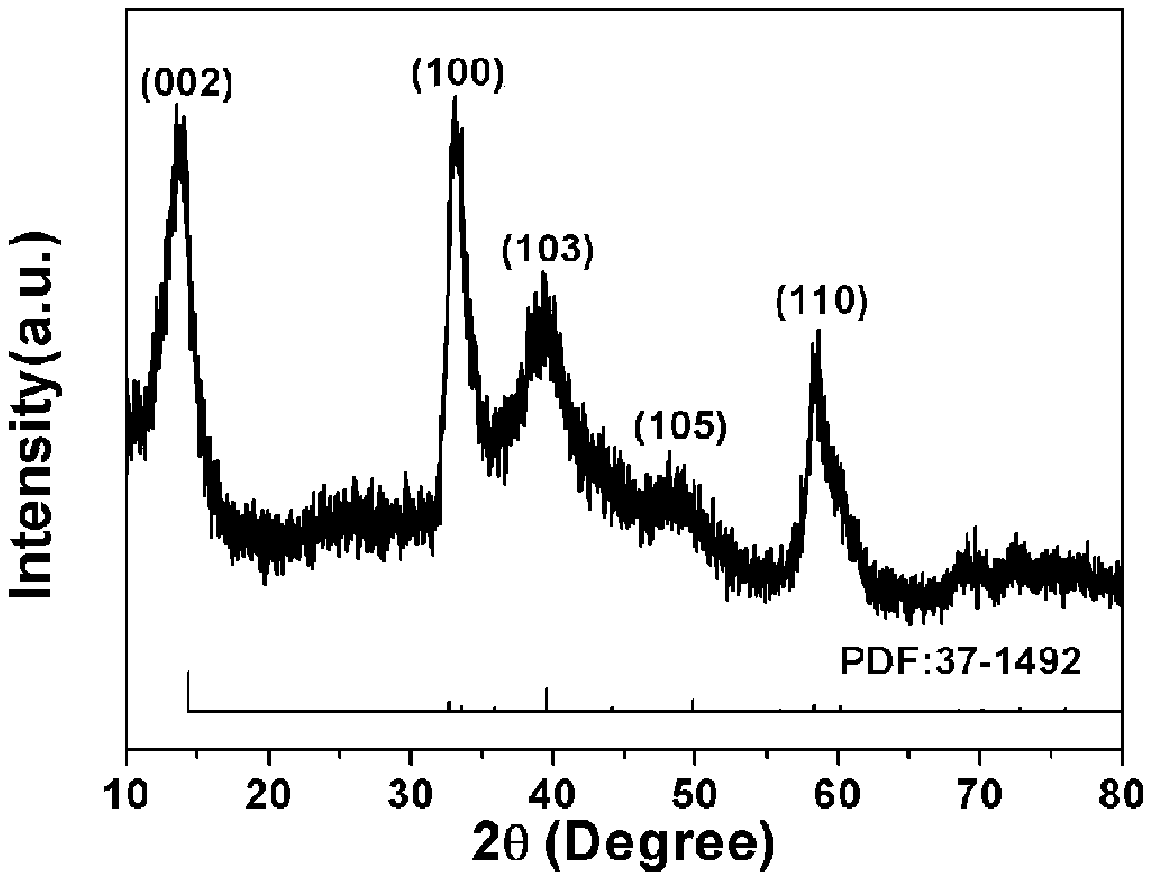

MoS2/nitrogen-doped carbon tube composite material and preparation method and application thereof

A composite material, nitrogen-doped carbon technology, used in nanotechnology for materials and surface science, electrical components, electrochemical generators, etc., can solve problems such as poor cycle performance and rate performance, and increase active sites. , The synthesis process is simple and controllable, and the repeatability is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Soak a common commercial melamine sponge (hereafter replaced by MS) in 0.1mol / L dilute hydrochloric acid for 12 hours to remove impurities, and then soak and wash it in deionized water until it is neutral. Dry it overnight at 80°C in a blast drying oven.

[0040] (2) Put the processed MS into an empty burning furnace (KSL-1100X, Hefei Kejing) and burn it at 400°C for 2 hours to obtain the template material NCT.

[0041] (3) Weigh 76.7mg ammonium molybdate tetrahydrate (AR analytical grade, Sinopharm) and 1g thiourea (AR,> 99%, Sinopharm), dissolve it in 20 mL of deionized water and sonicate it for 15 minutes to make it uniformly dispersed.

[0042] (4) Take the NCT obtained in step (2), drop the prepared solution into the sponge drop by drop until the sponge is saturated, and then transfer the sponge filled with the solution to a 50mL PTFE lining for hydrothermal reaction (180°C, 24h). After the reaction product was washed with deionized water several times, it was place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com