Structure of three-dimensional package and integration of optocoupler and method for three-dimensional package and integration of optocoupler

An optocoupler circuit and three-dimensional packaging technology, which is applied in the direction of circuits, electrical components, and electrical solid devices, can solve the problems of large occupied area, achieve the effect of reducing volume and facilitating flexible application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

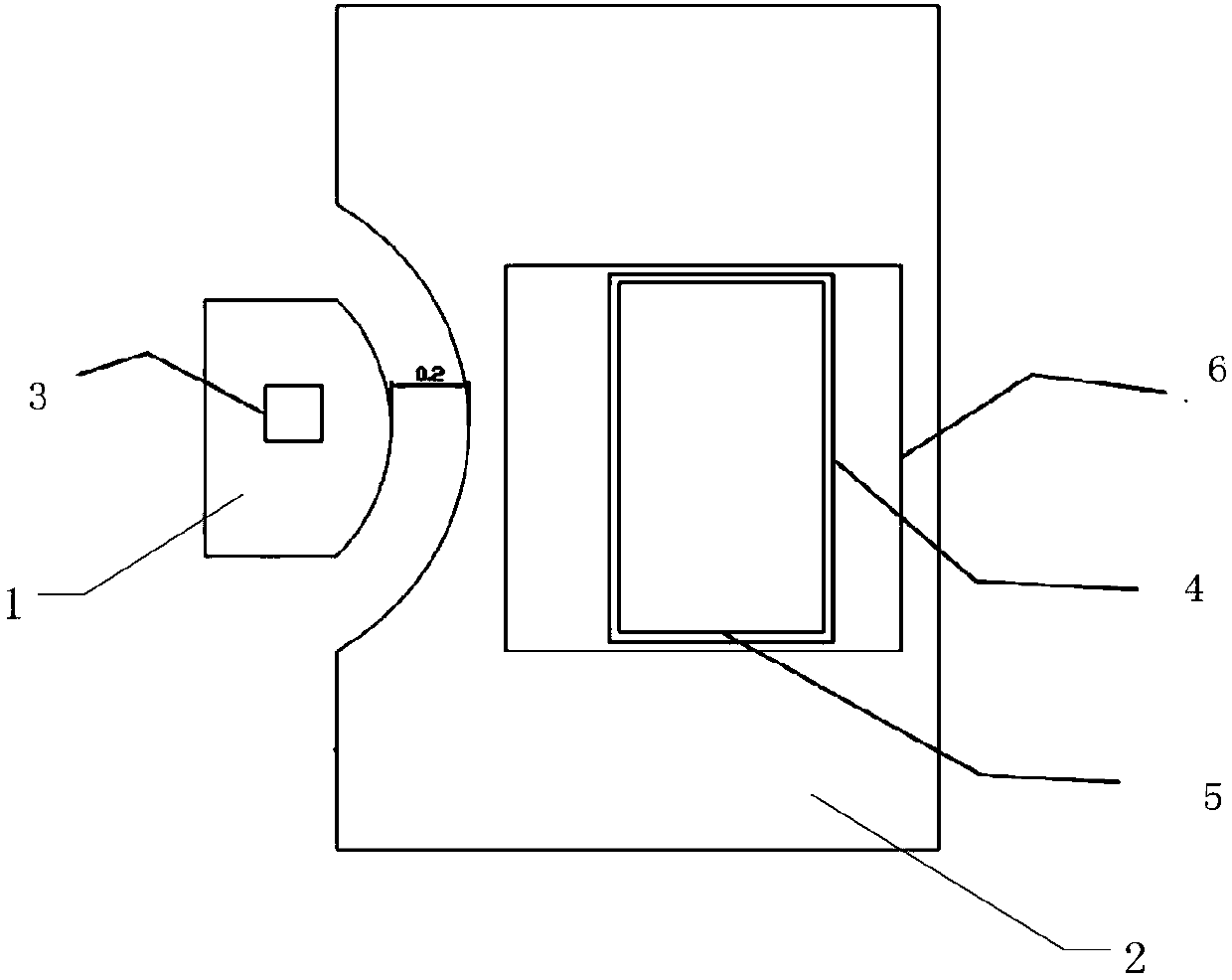

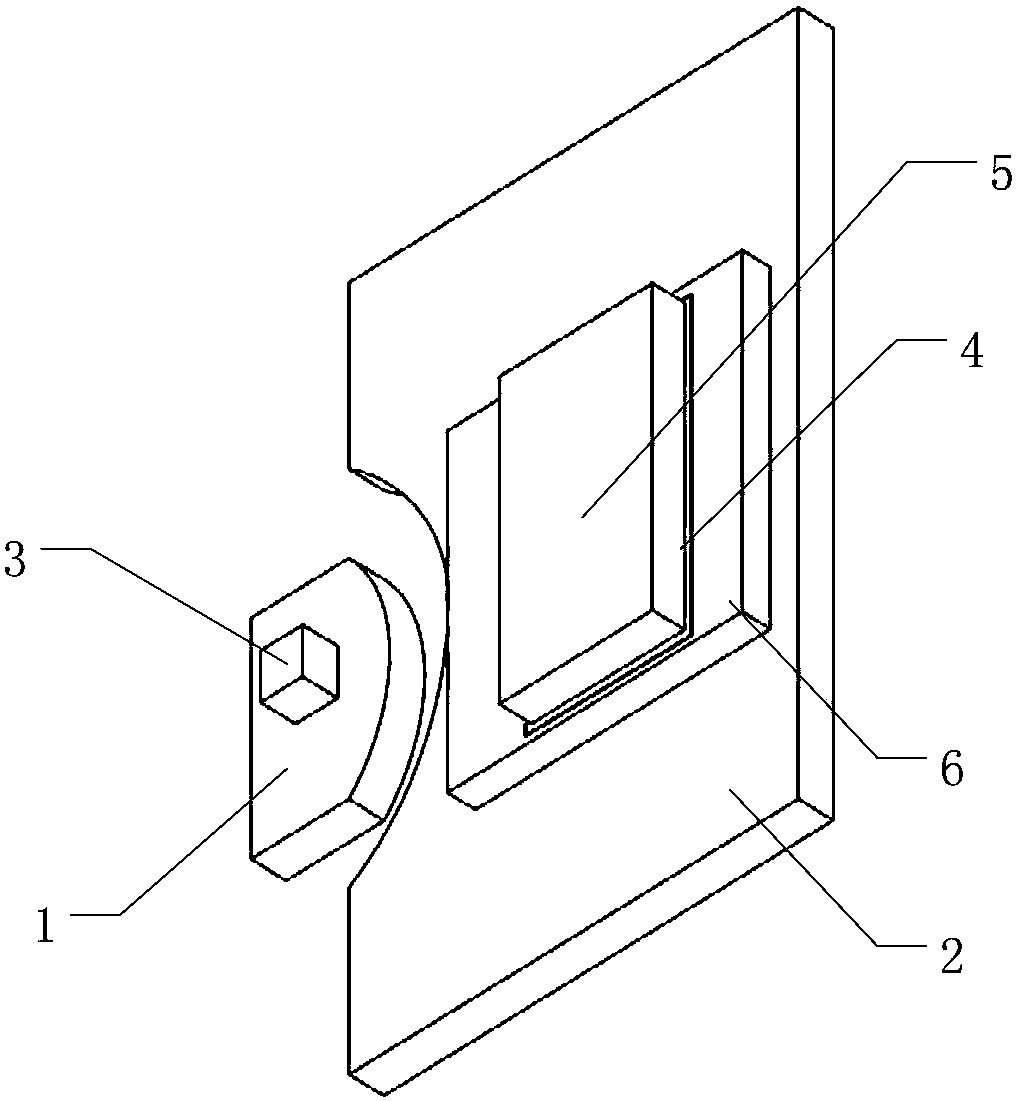

[0050] 1) Device installation; two independent base islands are set on the base material: the first base island 1 and the second base island 2 . The area of the first base island 1 is smaller than that of the second base island 2 . The adjacent edges of the first base island 1 and the second base island 2 are arc-shaped; the edge of the first base island 1 protrudes outward; the edge of the second base island 2 is concave inward; the arc of the first base island 1 The edge is surrounded by the arc edge of the second base island 2; the light source emitter chip 3 is placed near the arc edge of the first base island 1, and the signal is placed near the arc edge of the second base island 2. Trigger and amplify chip6. It also includes a light source receiver chip 5; after the light source receiver chip 5 is pasted with an insulating film 4 on the back, it is placed directly above the signal triggering and amplifying chip 6.

[0051] The interval between the first base island 1...

Embodiment 2

[0061] 1) Device installation; two independent base islands are set on the base material: the first base island 1 and the second base island 2 . The area of the first base island 1 is smaller than that of the second base island 2 . The adjacent edges of the first base island 1 and the second base island 2 are arc-shaped; the edge of the first base island 1 protrudes outward; the edge of the second base island 2 is concave inward; the arc of the first base island 1 The edge is surrounded by the arc edge of the second base island 2; the light source emitter chip 3 is placed near the arc edge of the first base island 1, and the signal is placed near the arc edge of the second base island 2. Trigger and amplify chip6. It also includes a light source receiver chip 5; after the light source receiver chip 5 is pasted with an insulating film 4 on the back, it is placed directly above the signal triggering and amplifying chip 6.

[0062] The interval between the first base island 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com