Heat-resisting and thermal-insulation cement infrastructure mortar and production method thereof

A heat-insulating cement and heat-resistant technology, applied in the field of slurry, can solve the problems of large drying shrinkage deformation, low tension-compression ratio, poor corrosion resistance, etc., and achieve the effects of low shrinkage, strong adhesion and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

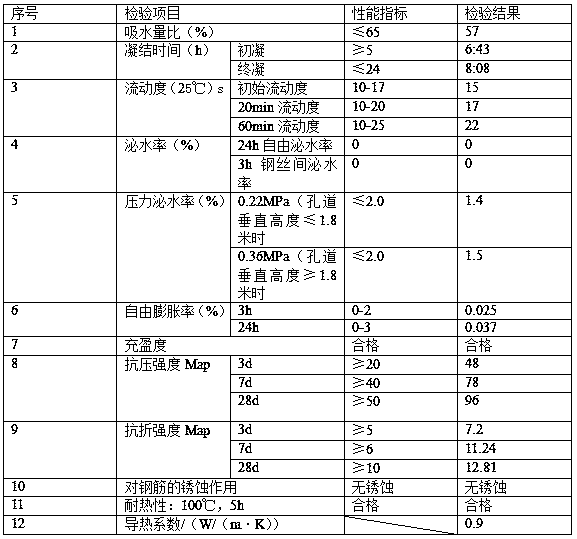

Embodiment 1

[0044] A heat-resistant and heat-preserving cement infrastructure mortar, which contains the following raw materials in parts by weight:

[0045] cementitious material: 80;

[0046] Heat-resistant and thermal insulation aggregate: 10;

[0047] Lignin-based water reducer: 0.4;

[0048] Rust inhibitor: 0.8;

[0049] Preservatives: 1.2;

[0050] Polyacrylate emulsion: 0.3;

[0051] Low viscosity cellulose ether: 0.3;

[0052] The gelling material comprises the following raw materials in parts by weight:

[0053] Portland cement: 30;

[0054] Ferric aluminate clinker: 5;

[0055] Active mineral admixture: 5;

[0056] Composite activator: 0.2;

[0057] The heat-resistant thermal insulation aggregate contains the following raw materials in parts by weight:

[0058] Quartz sand 100;

[0060] Polypropylene fiber 8;

[0061] Steel slag fine powder 40.

[0062] Portland cement is Portland cement with grades above 52.5.

[0063] The ferro-aluminat...

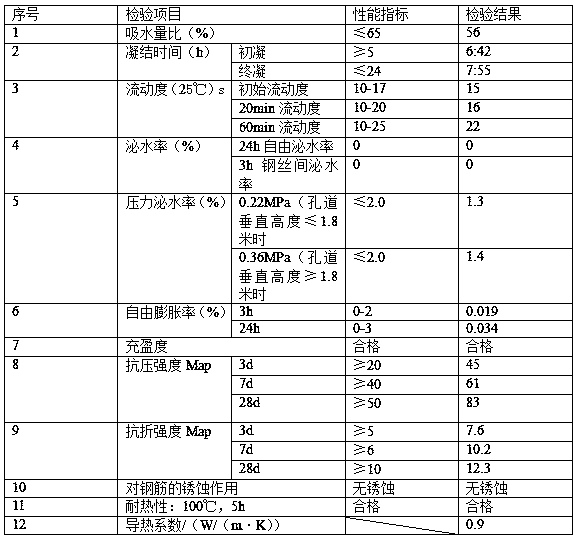

Embodiment 2

[0078] A heat-resistant and heat-preserving cement infrastructure mortar, which contains the following raw materials in parts by weight:

[0079] cementitious material: 90;

[0080] Heat-resistant and thermal insulation aggregate: 15;

[0081] Lignin-based water reducer: 0.5;

[0082] Rust inhibitor: 1;

[0083] Preservatives: 1.5;

[0084] Polyacrylate emulsion: 0.4;

[0085] Low viscosity cellulose ether: 0.4;

[0086] The gelling material comprises the following raw materials in parts by weight:

[0087] Portland cement: 40;

[0088] Ferric aluminate clinker: 8;

[0089] Active mineral admixture: 10;

[0090] Composite activator: 0.3;

[0091] The heat-resistant thermal insulation aggregate contains the following raw materials in parts by weight:

[0092] Quartz sand 110;

[0093] Brucite fiber 9;

[0094] Polypropylene fiber 9;

[0095] Steel slag fine powder 50.

[0096] Portland cement is Portland cement with grades above 52.5.

[0097] The ferro-aluminate...

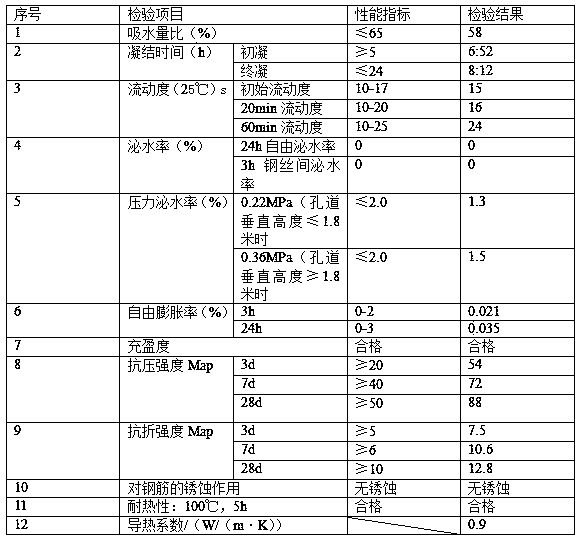

Embodiment 3

[0112] A heat-resistant and heat-preserving cement infrastructure mortar, which contains the following raw materials in parts by weight:

[0113] cementitious material: 100;

[0114] Heat-resistant insulation aggregate: 20;

[0115] Lignin-based water reducer: 0.6;

[0116] Rust inhibitor: 1.2;

[0117] Preservatives: 1.8;

[0118] Polyacrylate emulsion: 0.5;

[0119] Low viscosity cellulose ether: 0.5;

[0120] The gelling material comprises the following raw materials in parts by weight:

[0121] Portland cement: 50;

[0122] Ferric aluminate clinker: 10;

[0123] Active mineral admixture: 15;

[0124] Composite activator: 0.4;

[0125] The heat-resistant thermal insulation aggregate contains the following raw materials in parts by weight:

[0126] Quartz sand 120;

[0127] brucite fiber 10;

[0128] Polypropylene fiber 10;

[0129] Steel slag powder 60.

[0130] Portland cement is Portland cement with grades above 52.5.

[0131] The iron-aluminate clinker is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com