Golf club head alloy and preparation method thereof

A golf club head and alloy technology, which is applied in the field of alloys, can solve the problems of complex production process, difficult cutting process, poor process performance, etc., and achieve the effect of simple production process, low cost and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

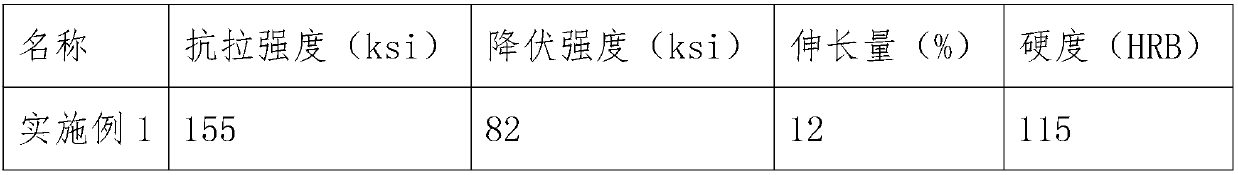

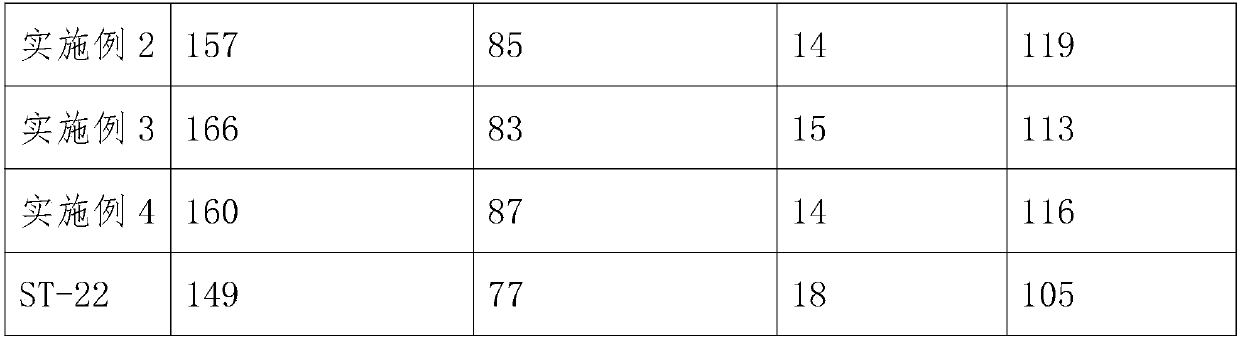

Examples

Embodiment Construction

[0019] In order to make the above-mentioned and other purposes, features and advantages of the present invention more obvious and understandable, the preferred embodiments of the present invention are specifically cited below for detailed description as follows:

[0020] A golf club head alloy, the weight percentage of ingredients is maintained at: 0.25-1.0% silicon, 0.25-1.5% manganese, 2.0-3.5% molybdenum, 6.0-8.0% nickel, 15.5-18.0% tungsten, 0.15-0.65% aluminum, 0.1-0.8% titanium, and the rest are iron and unavoidable impurities. The proportion of nickel in the molten alloy is more preferably 6.5-8.0%, the proportion of silicon is more preferably 0.5-1.0%, the proportion of manganese is more preferably 0.5-1.5%, the proportion of molybdenum is more preferably 2.5-3.5%, tungsten The proportion of aluminum is more preferably 16.5-17.5%, the proportion of aluminum is more preferably 0.20-0.60%, and the proportion of titanium is more preferably 0.2-0.7%.

[0021] The main pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com