A kind of high-strength epoxy honeycomb glue and preparation method thereof

An epoxy honeycomb, high-strength technology, used in epoxy resin adhesives, adhesives, polymer adhesive additives, etc., can solve the problems of unsuitable honeycomb composite panels, high cost, and achieve excellent high and low temperature resistance, adhesion The effect of small strength dispersion and good flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

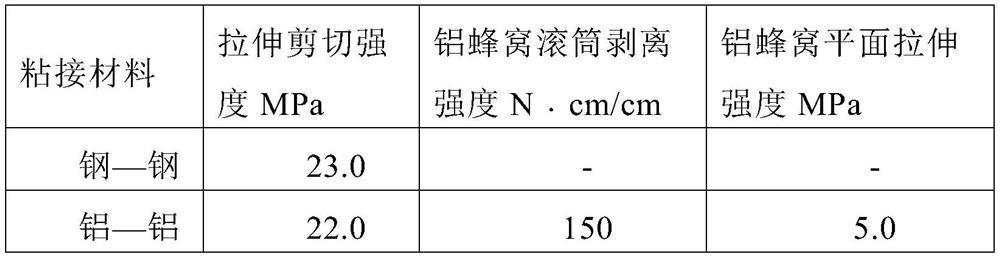

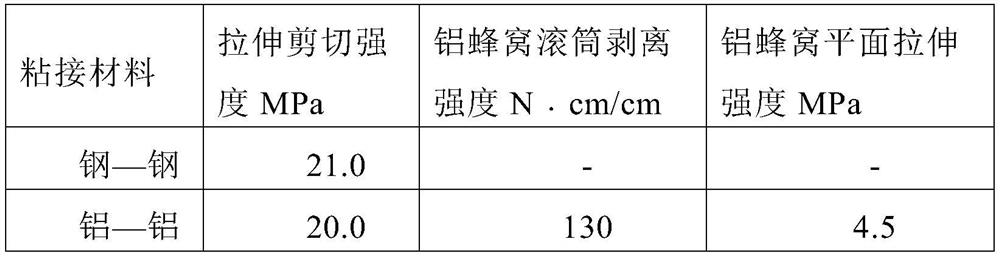

Examples

Embodiment 1

[0043] A kind of high-strength epoxy honeycomb glue and preparation method thereof, the method comprises the following steps:

[0044] First component preparation method

[0045] (1) Preheat 55 kg of E44 epoxy resin, 5 kg of glycidyl epoxy resin, and 8 kg of carboxyl-terminated liquid nitrile rubber modified epoxy resin, put them into the reaction kettle, stir and heat to 100-110°C Start keeping warm under the condition.

[0046] (2) Keep stirring and put 5 kg of superfine aluminum hydroxide, 15 kg of nano-calcium carbonate, and 2 kg of hydrophobic fumed silica into the reaction kettle, and turn on the vacuum defoaming, and stir at 100-110°C 1 to 2 hours, then began to cool.

[0047] (3) After cooling to 80-85°C, add 10 kg of the remaining phosphorus-nitrogen composite flame retardant, keep it warm, and continue stirring for about 1 hour under vacuum.

[0048] ⑷Inspect the performance of the adhesive and various indicators.

[0049] (5) Cool to about 50°C for weighing and pa...

Embodiment 2

[0058] A kind of high-strength epoxy honeycomb glue and preparation method thereof, the method comprises the following steps:

[0059] First component preparation method

[0060] (1) Preheat 40 kg of E44 epoxy resin, 12 kg of E42 epoxy resin, 3 kg of butyl glycidyl ether, and 10 kg of carboxyl-terminated liquid nitrile rubber modified epoxy resin, put them into the reaction kettle, stir and When the heating reaches 100-110°C, heat preservation starts.

[0061] (2) Keep stirring and put 5 kg of ultra-fine magnesium hydroxide as a reinforcing filler, 20 kg of ultra-fine active silica powder, and 2 kg of hydrophobic fumed silica into the reaction kettle, and turn on the vacuum defoaming. Stir for 1-2 hours, then start to cool.

[0062] (3) After cooling to 80-85°C, add 10 kg of the remaining phosphorus-nitrogen composite flame retardant, keep it warm, and continue stirring for about 1 hour under vacuum.

[0063] ⑷Inspect the performance of the adhesive and various indicators. ...

Embodiment 3

[0073] A high-strength epoxy honeycomb glue, when used, the first component and the second component are mixed at a weight ratio of 2-4:1, and the first component is prepared by using the following raw materials in parts by weight: epoxy resin 30. Low-viscosity epoxy resin 5, active toughening agent 3, reinforcing filler 10, flame retardant 10, thixotropic agent 0.3, the second component is prepared from the following raw materials in parts by weight: toughening curing agent 50 , hardening curing agent 10, coupling agent 0.3.

[0074] The epoxy resin used is bisphenol S type epoxy resin. The viscosity of the low-viscosity epoxy resin is not more than 10000mPa·s at normal temperature, and the epoxy resin of pyrogallol triglycidyl ether is used. The active toughening agent is carboxyl-terminated liquid nitrile rubber, and the reinforcing filler is nano-sized alumina. The flame retardant is decabromodiphenyl ether. The thixotropic agent is fumed silica. The toughening and cur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com