Y-Sb-Te phase-change material, phase-change memory unit and preparation method thereof

A phase-change memory and phase-change material technology, applied in the field of semiconductor material preparation, can solve the problems of poor data retention, low crystallization temperature, and low high-to-low resistance ratio, and achieve fast crystallization speed, adjustable composition, and high deposition. The effect of state stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

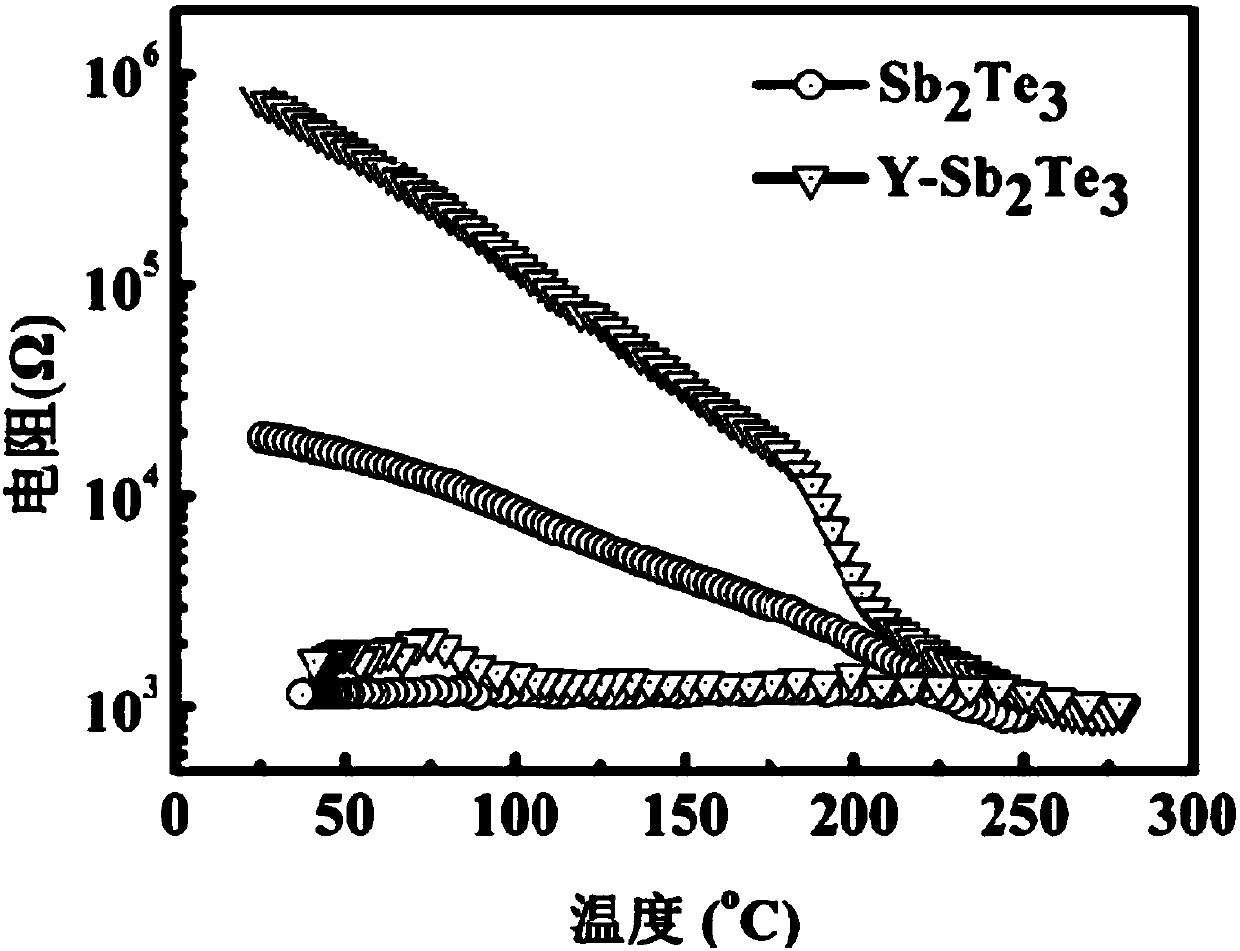

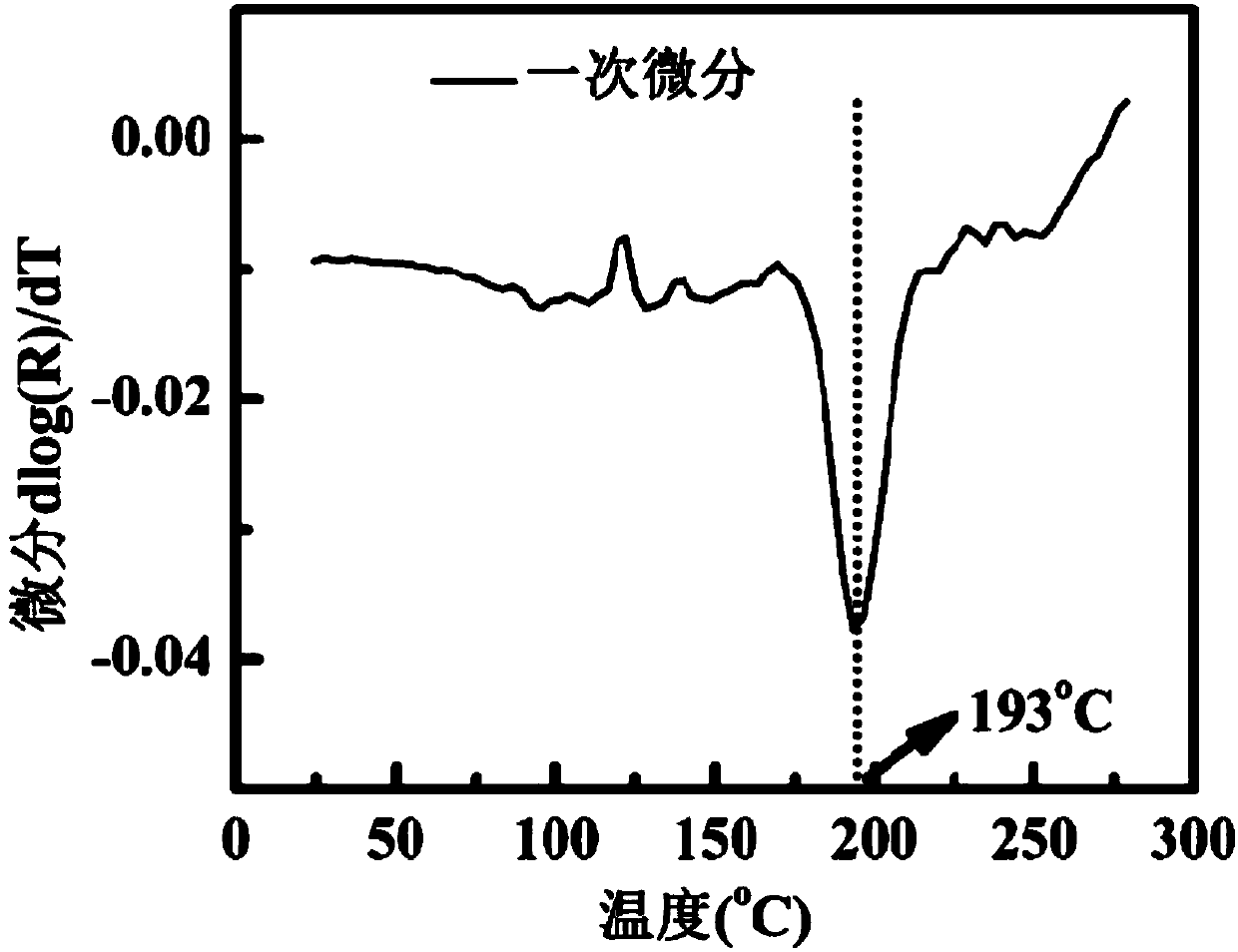

[0033] In this example, Y 100-x-y Sb x Te y (x / y=2 / 3) phase change material, and test it to further illustrate a technical solution of the present invention. The specific preparation plan is as follows:

[0034] Prepare Y on the silicon substrate and the thermally oxidized silicon substrate by using the dual-target co-sputtering method in magnetron sputtering 100-x-y Sb x Te y Phase change material, where 0 <100-x-y <50, 0.5≤x / y≤4. The prepared Y-Sb-Te series phase change material is a thin film material, and the thickness of the thin film can be controlled at 100nm~250nm by adjusting the long film time.

[0035] Specifically, it includes the following steps: under an argon atmosphere, using Sb 2 Te 3 Alloy target and Y elemental target are co-sputtered. Among them, Sb 2 Te 3 The alloy target uses a DC power supply, and the Y single-mass target uses a radio frequency power supply; by changing the radio frequency power to adjust the atomic percentage of Y, a Y-Sb-Te series of phase ...

Embodiment 2

[0040] In this example, Y 100-x-y Sb x Te y (x / y=2 / 1) phase change material, and test it to further illustrate a technical solution of the present invention. The specific preparation plan is as follows:

[0041] Prepare Y on the silicon substrate and the thermally oxidized silicon substrate by using the three-target co-sputtering method in magnetron sputtering 100-x-y Sb x Te y Phase change material, where 0 <100-x-y <50, 0.5≤x / y≤4. The prepared Y-Sb-Te series phase change material is a thin film material, and the thickness of the thin film can be controlled at 100nm~250nm by adjusting the long film time.

[0042] Specifically, it includes the following steps: under an argon atmosphere, using Sb 2 Te 3 Alloy target, Sb elemental target and Y elemental target are co-sputtered with three targets. Among them, Sb 2 Te 3 The alloy target and the Sb elementary target use a DC power supply, and the Y elementary target uses a radio frequency power supply; by changing the radio frequency po...

Embodiment 3

[0047] In this example, Y 100-x-y Sb x Te y (x / y=1 / 2) phase change material, and test it to further illustrate a technical solution of the present invention. The specific preparation plan is as follows:

[0048] Prepare Y on the silicon substrate and the thermally oxidized silicon substrate by using the three-target co-sputtering method in magnetron sputtering 100-x-y Sb x Te y Phase change material, where 0 <100-x-y <50, 0.5≤x / y≤4. The prepared Y-Sb-Te series phase change material is a thin film material, and the thickness of the thin film can be controlled at 100nm~250nm by adjusting the long film time.

[0049] Specifically, it includes the following steps: under an argon atmosphere, using Sb 2 Te 3 Alloy target, Te elemental target and Y elemental target are co-sputtered with three targets. Among them, Sb 2 Te 3 The alloy target and the Te elementary target use a DC power supply, and the Y elementary target uses a radio frequency power supply; by changing the radio frequency po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com