A low-power charge-trap memory based on graphene oxide quantum dots and its preparation method

A technology of graphene quantum dots and charge trapping, applied in the direction of electric solid-state devices, circuits, electrical components, etc., can solve the problems of high operating voltage and large power consumption, and achieve low power consumption, long-lasting data storage, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

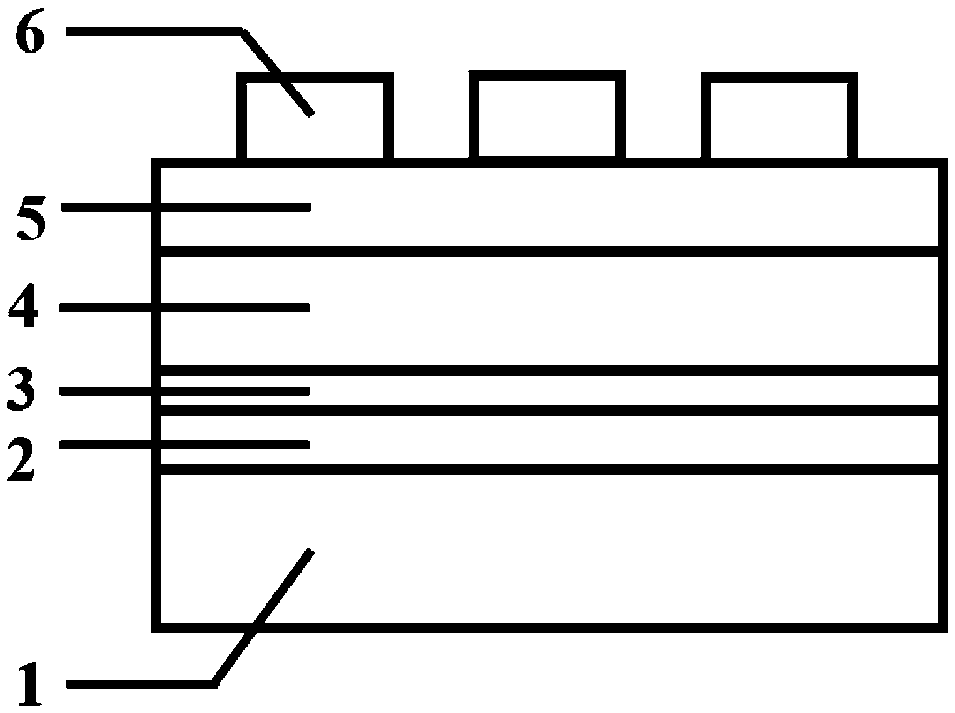

[0035] The charge trapping memory structure prepared by the present invention is as figure 1 As shown, its structure is that SiO is sequentially integrated on Si substrate 1 2 Tunneling layer 2, GQODs / Zr 0.5 Hf 0.5 o 2 Trapping layer, SiO 2 Barrier layer 5, Pd electrode film layer 6, GQODs / Zr 0.5 Hf 0.5 o 2 The trapping layer consists of GQODs layer 3 and Zr 0.5 Hf 0.5 o 2 layer 4, and the GQODs layer 3 is a single-layer graphene oxide quantum dot layer.

[0036] Si substrate 1 is p-type Si material with 100 crystal orientation; SiO 2 The thickness of tunneling layer 2 is 2~5nm; GQODs / Zr 0.5 Hf 0.5 o 2 The trapping layer 4 has a thickness of 5-80nm, preferably 10-40nm; SiO 2 The barrier layer 5 has a thickness of 5-50 nm, most preferably 5-20 nm; the Pd electrode film layer 6 is a circular electrode film with a thickness of 20-150 nm and a diameter of 60-300 μm.

Embodiment 2

[0038] The preparation method of the charge trapping memory of the present invention, the steps are as follows:

[0039] (a) The p-Si substrate was cleaned with ultrasonic waves in acetone, alcohol and deionized water in sequence, and then washed with HF solution (volume ratio H 2 O:HF=2:1) wash for 2min, then ultrasonically clean with deionized water, take it out and use N 2 Blow dry; put the processed silicon substrate into a high-temperature annealing furnace, and anneal and grow SiO in an oxygen environment 2 Tunneling layer: first use 20s to rise from room temperature to 200°C, 60s to rise from 200°C to 500°C, keep at 500°C for 150s, 10s to drop to 100°C, 40s to drop from 100°C to room temperature, the obtained SiO 2 The thickness of the tunneling layer is 3nm, resulting in SiO 2 / Si structure substrate.

[0040] (c) SiO 2 The / Si structure substrate is placed on the rotating suction cup of the SC-1B homogenizer, and the rotation speed is set to 4000r / min. Use a rub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com