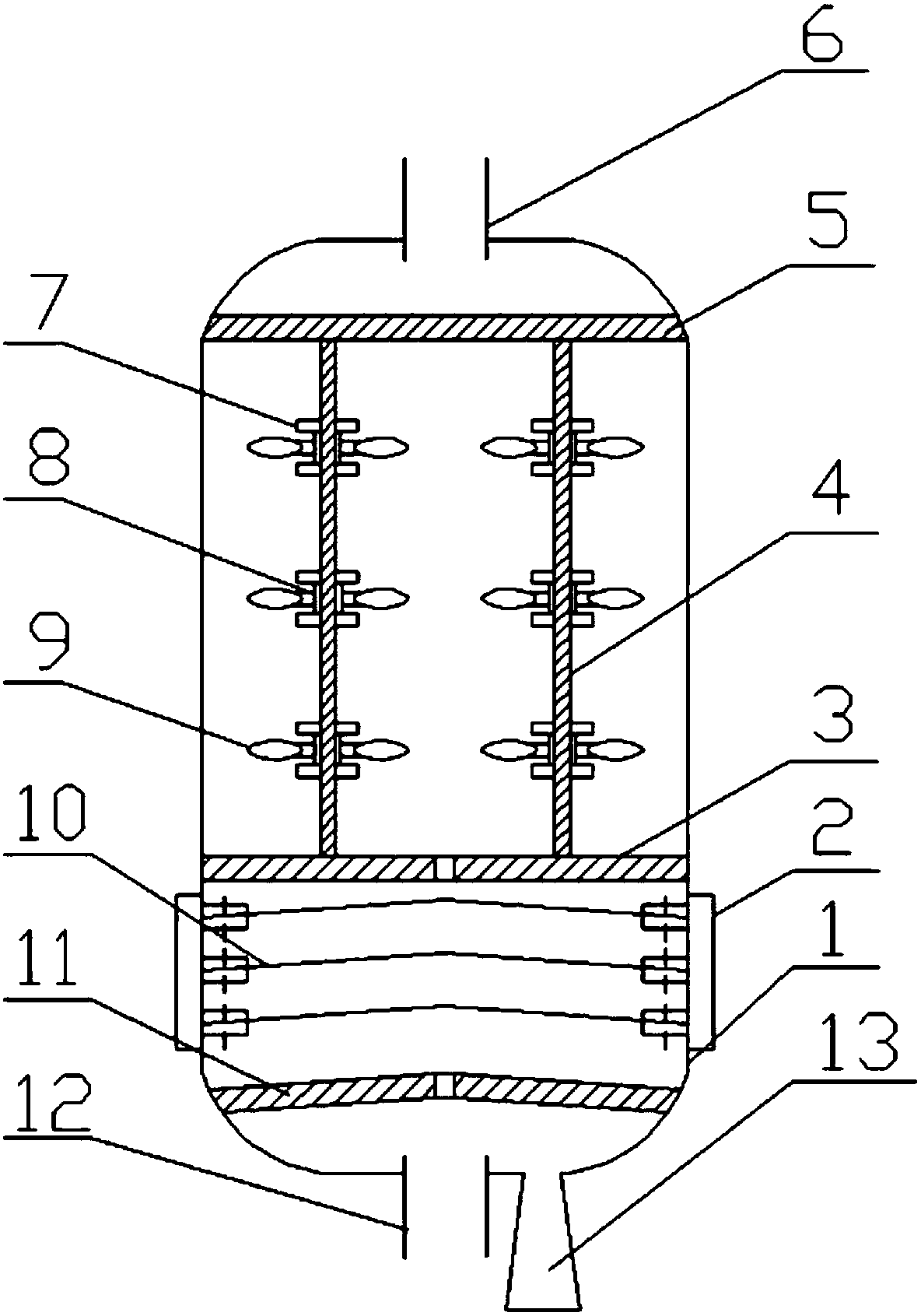

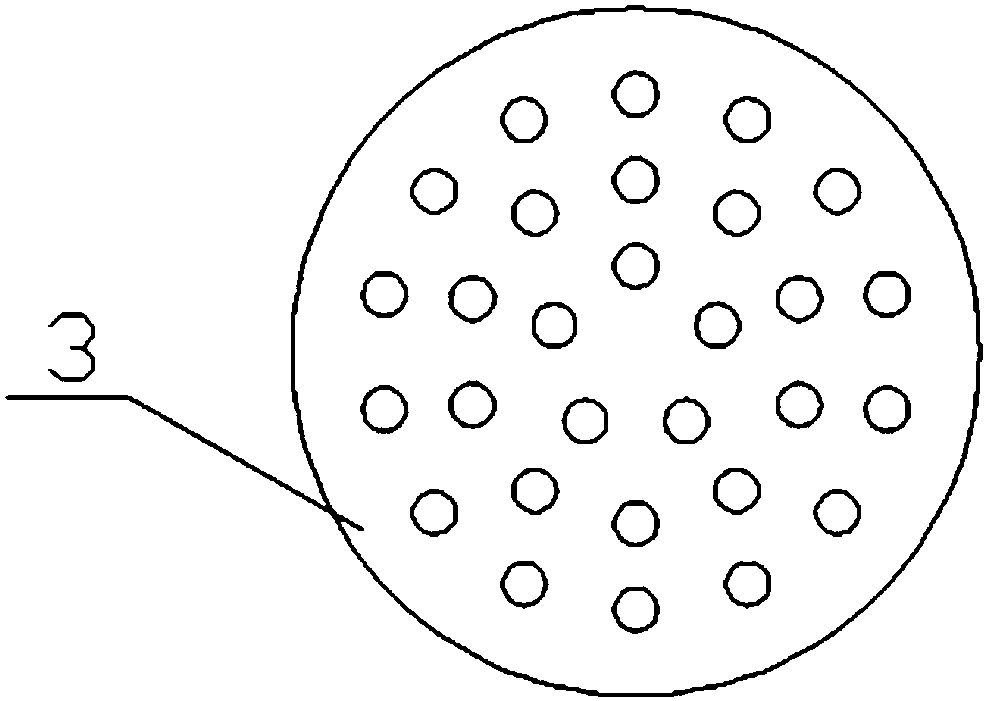

High-efficiency tubular heat exchanger device based on surface modification and heat exchange system

A tubular heat exchanger, surface modification technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the tail gas waste heat recovery process that is not suitable for the pressure drop requirement, and the heat recovery is difficult to be effective for a long time Problems such as the reduction of the heat transfer efficiency of the heat exchanger, etc., to achieve the effect of reducing the thickness, reducing the gas resistance, and improving the heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] The medium in the pipe is air, which is transported by the fan, flows through the regulating valve, and then enters the inner pipe of the tubular heat exchanger (internal components are installed in the pipe) after passing through the regulating valve to measure the flow rate. The steam is produced by the steam generator through the pipe gap. The preliminarily designed spin inner member can rotate automatically under the drive of semi-coke exhaust gas. A comparative experiment was carried out on the above devices

[0072] Group 1 is the modified group. The heat exchanger shell 1 and the spin-disturbed internal member 9 are modified by electroplating and spraying oleophobic and hydrophobic materials. High-temperature steam carries distillate oil into the high-efficiency tubular heat exchanger;

[0073] Group 2 is the unmodified group. Put the heat exchanger horizontally into the dirty oil scale tank (distillate oil produced in the low-temperature dry distillation produc...

Embodiment 2

[0077] Using the same outer diameter cylinder, the same number of internal components and the same flow conditions, the heat transfer and pressure drop performance of the spin turbulence internal component heat exchanger of the present invention and the existing flat internal component heat exchanger were tested, and the experimental results Such as Figure 5 and Figure 6 Shown:

[0078] Depend on Figure 5 It can be seen that the Nusselt number Nu of the spin-disturbed internal heat exchanger is about 140, while the Nusselt number Nu of the stationary flat-plate internal heat exchanger is about 75. It can be seen that the spin-disturbed The heat transfer performance of the flow internal heat exchanger is significantly better than that of the static flat plate turbulent internal heat exchanger.

[0079] Depend on Figure 6 It can be seen that the pressure drop of the spin-disturbed inner member heat exchanger is about 3500Pa, and the pressure drop of the static flat-plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com