Bacillus addisoni capable of producing neutral raw starch digesting amylase

A technology of Bacillus arborii and raw starch, applied in the field of bioengineering, can solve the problems of insufficient activity of bacteria, poor enzymolysis or fermentation effect, loss of enzyme activity, etc., and achieve the effect of strong ability to hydrolyze raw starch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1 produces the screening of amylase strain

[0044] Soil samples were collected from 10-20cm shallow soil of cassava fields in Wuming District and Suining District, Nanning City, Guangxi, and a total of 16 soil samples were collected. Weigh 2g of soil sample into a 250mL Erlenmeyer flask, add 20mL of sterile saline. Stir on a magnetic stirrer for about 30 minutes, take the suspension and heat-treat at 80°C for 15 minutes to kill the vegetative cells, and then enrich and culture at 37°C for 24 hours. Then take the enriched culture solution for gradient dilution (10 3 、10 4 、10 5 and 10 6 ), 50 μL each was spread on a screening medium plate with tapioca starch as the sole carbon source, and cultured at 30°C for 2 days. Observe the growth of the colony, and add 0.05% dilute iodine solution dropwise, measure the diameter (D) of the transparent circle around the colony and the diameter (d) of the colony, and calculate their ratio.

[0045] Select 58 colonies...

Embodiment 2

[0046] Embodiment 2 produces the identification of amylase strain

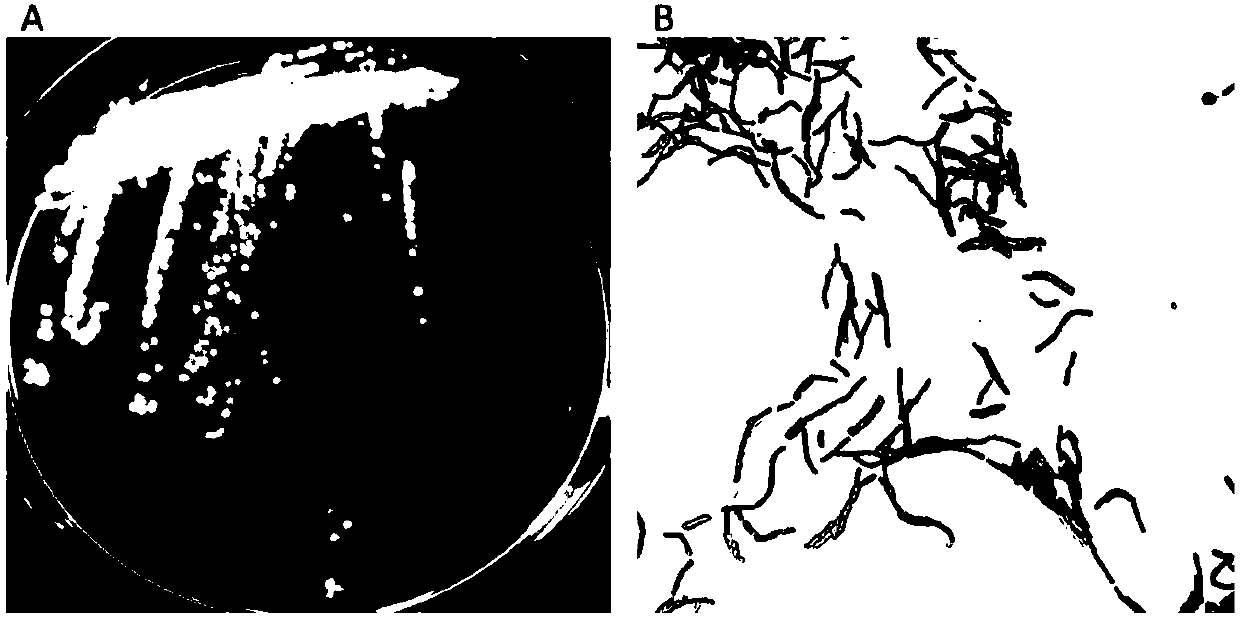

[0047] (1) Colony characteristics and cell morphology

[0048] The colonies on the solid screening plate are round and regular, with smooth edges, raised surface, milky white, moist, opaque, easy to provoke, and wrinkle-free ( figure 1 ). It is white waxy when observed against light. The colonies will be slightly yellow if cultured for a long time. Microscopically, the bacteria were long rod-shaped, with spores, and Gram staining was positive.

[0049] (2) Physiological and biochemical characteristics

[0050] The starch hydrolysis test was positive. Catalase, oxidase, urease, galactosidase, and phosphatase tests were positive. Trypsin, oxidase (Kovacs), aromatase, and indole tests were negative. The methyl red test was negative. Can utilize glucose, xylose, arabinose, mannose, raffinose. Lactose, acetate, sorbitol, rhamnose cannot be utilized.

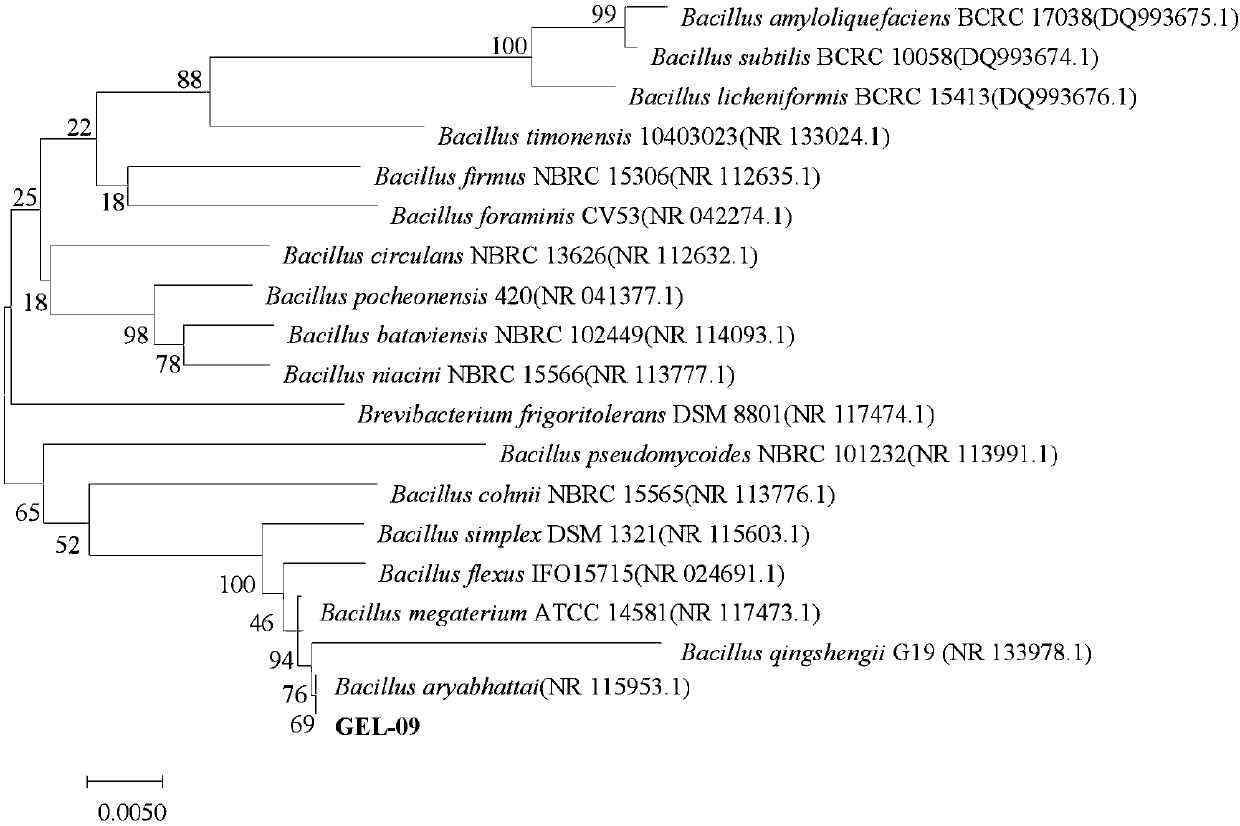

[0051] (3) 16S rDNA sequence analysis

[0052] Inocul...

Embodiment 3

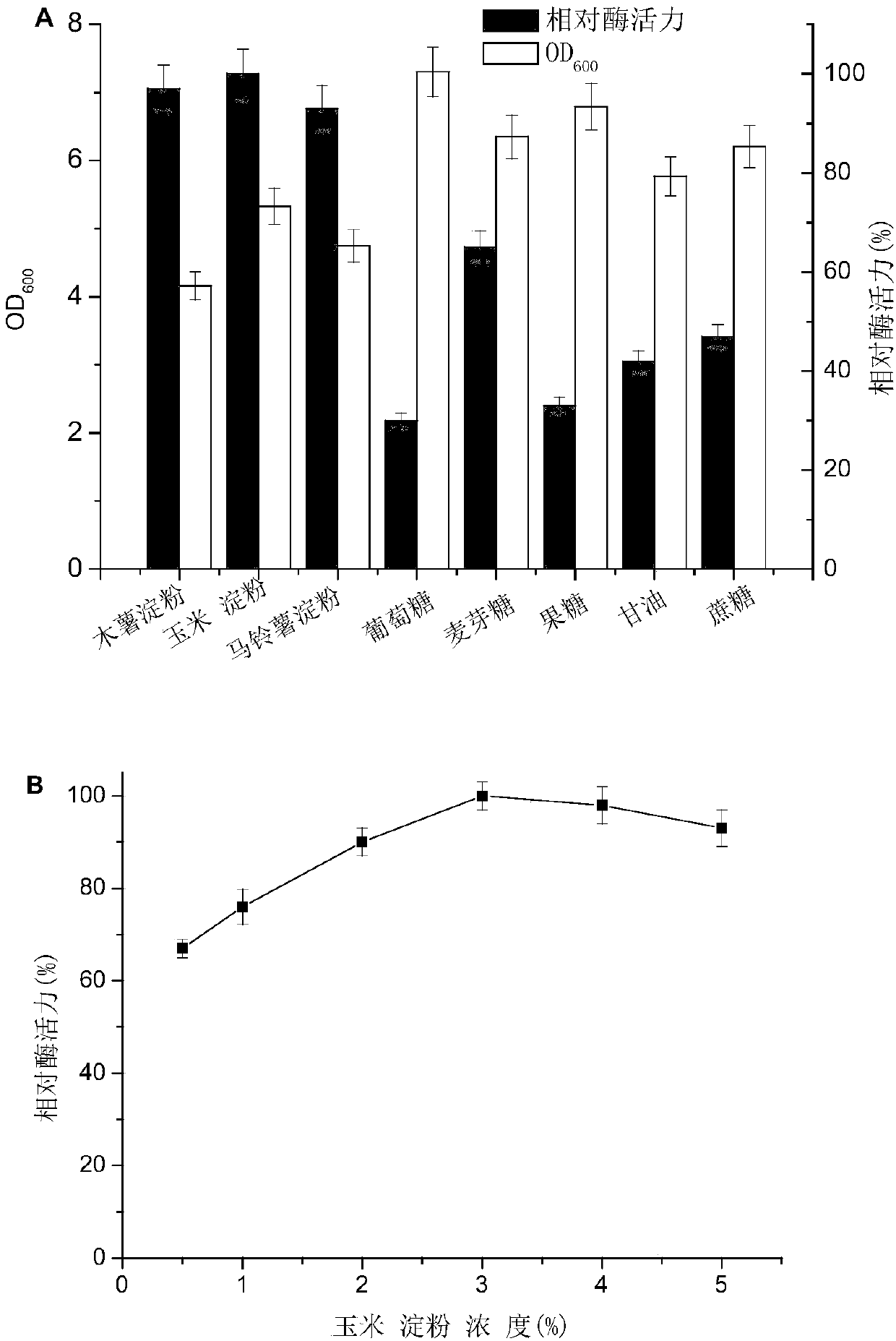

[0056] The influence of embodiment 3 different carbon sources on thalline growth and enzyme production

[0057] The preserved Bacillus arzii was inoculated into the seed medium, and cultured in a shaker flask at 37° C. and 200 rpm for 12 hours as seeds. The seeds were inoculated into the fermentation medium with an inoculation amount of 2.5% (V / V), and the shaker was shaken at a rotational speed of 200 r / min.

[0058] Tapioca starch, corn starch, potato starch, glucose, maltose, fructose, glycerol, and sucrose were used as carbon sources for the fermentation of strain GEL-09, and other medium components and conditions were unchanged. The bacterial concentration and enzyme activity were measured after fermentation. The result is as image 3 As shown in A, when different types of starch are used as carbon sources, the growth of bacteria is low, but the activity of enzymes produced is high; when monosaccharides, disaccharides, and glycerol are used as carbon sources, although th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com