Gas phase polyethylene catalyst and preparation method thereof

A catalyst and polyethylene technology, applied in the application field of the catalyst in ethylene polymerization or copolymerization, can solve the problems of uneven shape of catalyst particles, harm to production personnel, increase energy consumption and material consumption, etc., to ensure long-term stable operation, The effect of reducing fine powder content and dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Catalyst preparation:

[0054] (1) Under the protection of high-purity nitrogen, 180 mL of n-heptane, 3.0 g of anhydrous magnesium chloride and 11.5 mL of n-butanol were sequentially added to a 1L reactor with a mechanical stirrer, and the temperature was raised to 85°C for 3 hours to obtain a Homogeneous solution A,

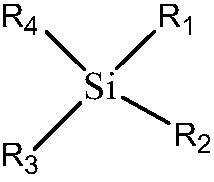

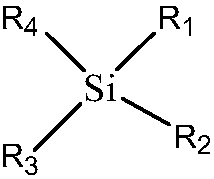

[0055] (2) Add 0.2 mol of orthosilicate electron donor to reactant A at 85°C, and react at this temperature for 1.0 hour to obtain reactant B;

[0056] (3) Lower the temperature of the above-mentioned reactant B solution to 60°C, and add 36 g of heat-activated SiO 955 to the reactant B. 2 , reacted for 5 hours to obtain reactant C;

[0057] (4) At 60°C, wash reactant C with n-hexane for 5 times to obtain reactant D, and finally dry it with high-purity nitrogen at 80°C to obtain white solid powder MgCl 2 / SiO 2 Composite carrier;

[0058] (5) Add the above reactant D into 100mL of n-heptane, then slowly add 8mL of titanium tetrachloride solution dropw...

Embodiment 2

[0064] Catalyst preparation:

[0065] (1) Under the protection of high-purity nitrogen, 120 mL of n-heptane, 3.0 g of anhydrous magnesium chloride and 15.0 mL of n-butanol were sequentially added to a 1L reactor with a mechanical stirrer, and the temperature was raised to 60°C for 5 hours to obtain a Homogeneous solution A,

[0066] (2) Add 0.01 moL of γ-isocyanatopropyltriethoxysilane electron donor to reactant A at 60°C, and react at this temperature for 2.0 hours to obtain reactant B;

[0067] (3) Lower the temperature of the above-mentioned reactant B solution to 70°C, add 15 g of heat-activated SiO 955 to the reactant B 2 , reacted for 4 hours to obtain reactant C;

[0068] (4) At 50°C, wash reactant C with n-hexane for 5 times to obtain reactant D, and finally dry it with high-purity nitrogen at 90°C to obtain white solid powder MgCl 2 / SiO 2 Composite carrier;

[0069] (5) Add the above reactant D into 100mL of n-heptane, then slowly add 10mL of titanium tetrachlor...

Embodiment 3

[0074] Catalyst preparation:

[0075] (1) Under the protection of high-purity nitrogen, 240 mL of n-heptane, 3.0 g of anhydrous magnesium chloride and 15.0 mL of n-butanol were sequentially added to a 1L reactor with a mechanical stirrer, and the temperature was raised to 70°C for 4 hours to obtain a Homogeneous solution A,

[0076] (2) At 70°C, add 0.2 mol of dipyrrolyldimethoxysilane and 0.3 mol of bisperhydroisoquinoline dimethoxysilane to reactant A, and react at this temperature for 1.5 hours to obtain the reactant B;

[0077] (3) Lower the temperature of the reactant B solution to 30°C, and add 30 g of heat-activated SiO 955 to the reactant B. 2 , reacted for 5 hours to obtain reactant C;

[0078] (4) Wash reactant C 5 times with n-hexane at 80°C to obtain reactant D, and finally dry it with high-purity nitrogen at 80°C to obtain white solid powder MgCl 2 / SiO 2 Composite carrier;

[0079] (5) Add the above reactant D into 150mL of n-heptane, then slowly add 10mL o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com