Method of recycling amygdalin in bitter apricot seed debitterizing water by macroporous resin process

A macroporous resin, amygdalin technology, applied in chemical instruments and methods, preparation of sugar derivatives, sugar derivatives, etc., to achieve the effects of low cost, reduced waste water discharge, and simplified purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The debittering of bitter almonds in this embodiment is to mix bitter almonds with water at a ratio of 1:10kg / kg at 60°C, soak for 8 hours, and obtain an aqueous solution.

[0027] (1) Concentrate the bitter almonds to a concentration of 90% after filtering the debittered water to obtain a concentrated solution of bitter almonds;

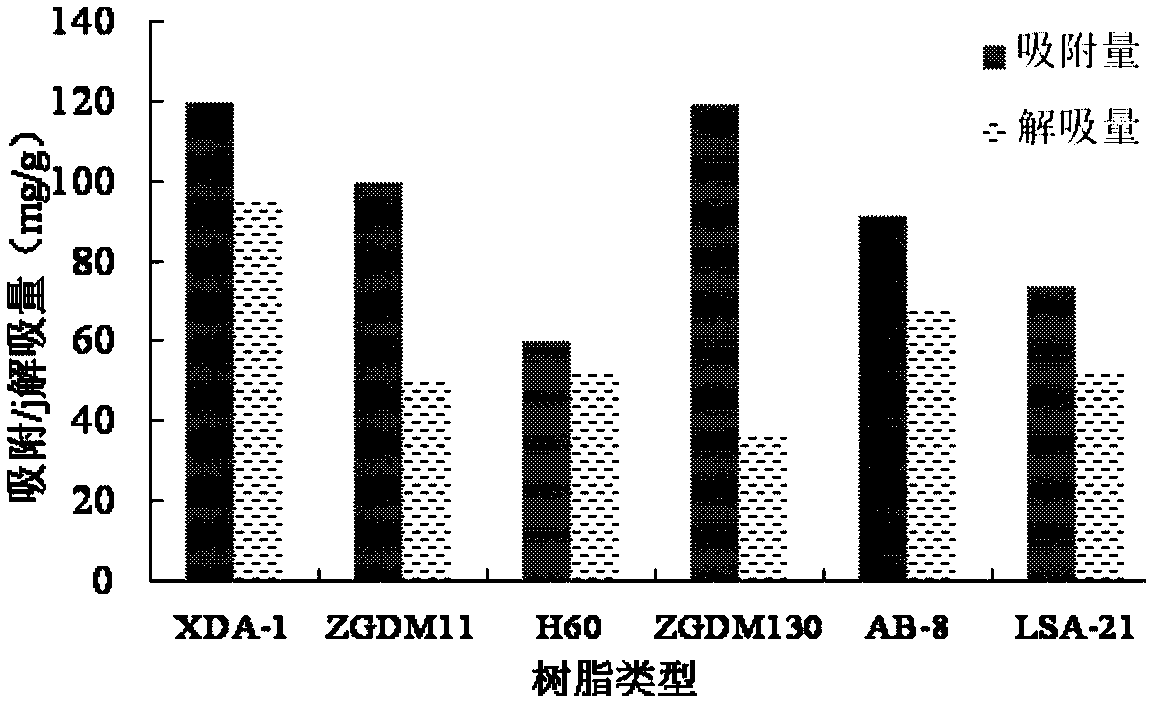

[0028] (2) the bitter almond concentrated solution of step (1) is used for XDA-1 type macroporous resin column chromatography, and the loading amount when adjusting column chromatography is 78.05mg / mL, flow rate is 2mL / min;

[0029] (3) Desorb the saturated macroporous resin with a concentration of 80% ethanol solution as eluent, the desorption time is determined to be 4.5h, and then use the vacuum concentration method at a vacuum degree of 60kPa and a concentration temperature of 60°C. Concentrate in vacuo for 4 hours to concentrate the eluent to a water content below 30%;

[0030] (4) Vacuum freeze-dry the above-mentioned concentrated elua...

Embodiment 2

[0032] The debittering water of bitter almonds in this embodiment is to mix bitter almonds and water at a ratio of 1:15kg / kg at 55°C, soak for 5 hours, and obtain an aqueous solution.

[0033] (1) Concentrate the bitter almonds to a concentration of 80% after filtering the debittered water to obtain the bitter almond concentrate;

[0034] (2) The bitter almond concentrated solution of step (1) is used for ZGDM11 type macroporous resin column chromatography, and the loading amount when adjusting column chromatography is 65mg / mL, and flow rate is 2mL / min;

[0035] (3) Desorb the saturated macroporous resin with a concentration of 60% ethanol solution as an eluent, and then use a vacuum concentration method to concentrate in vacuum for 6 hours at a vacuum degree of 55kPa and a concentration temperature of 50°C to make the eluted Concentrate the liquid until the water content is below 30%;

[0036] (4) Vacuum freeze-dry the above-mentioned concentrated eluate, control the tempera...

Embodiment 3

[0038] The debittering of bitter almonds in this embodiment is to mix bitter almonds with water at a ratio of 1:10kg / kg at 75°C, soak for 6 hours, and obtain an aqueous solution.

[0039] (1) Concentrate the bitter almonds to a concentration of 85% after filtering the debittered water to obtain the bitter almond concentrate;

[0040] (2) the bitter almond concentrated solution of step (1) is subjected to AB-8 type macroporous resin column chromatography, and the loading amount when adjusting the column chromatography is 35.70 mg / mL, and the flow rate is 2 mL / min;

[0041] (3) Desorb the saturated macroporous resin with a concentration of 50% ethanol solution as an eluent, and then use a vacuum concentration method to concentrate in vacuum for 2 hours at a vacuum degree of 80kPa and a concentration temperature of 65°C to make the eluent Concentrate the liquid until the water content is below 30%;

[0042] (4) Vacuum freeze-dry the above-mentioned concentrated eluate, control t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com