Petrochemical wastewater discharge treatment device

A technology for wastewater discharge and treatment equipment, which is applied in special compound water treatment, oxidized water/sewage treatment, water/sewage treatment, etc. Due to the limited effect of biochemical process, the effect of improving wastewater treatment efficiency, short time required for film hanging and easy adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

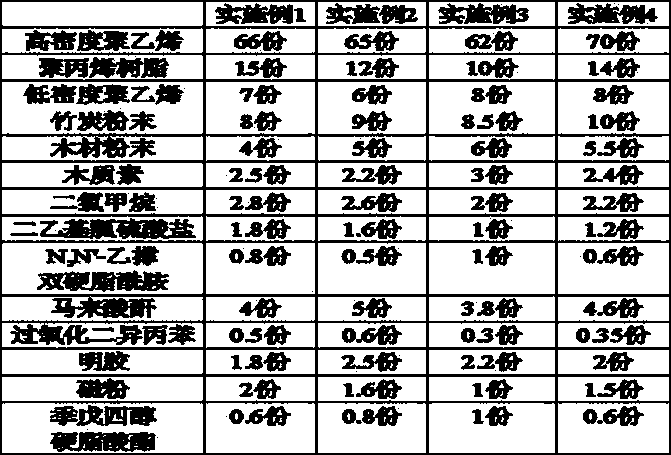

Embodiment 1~4

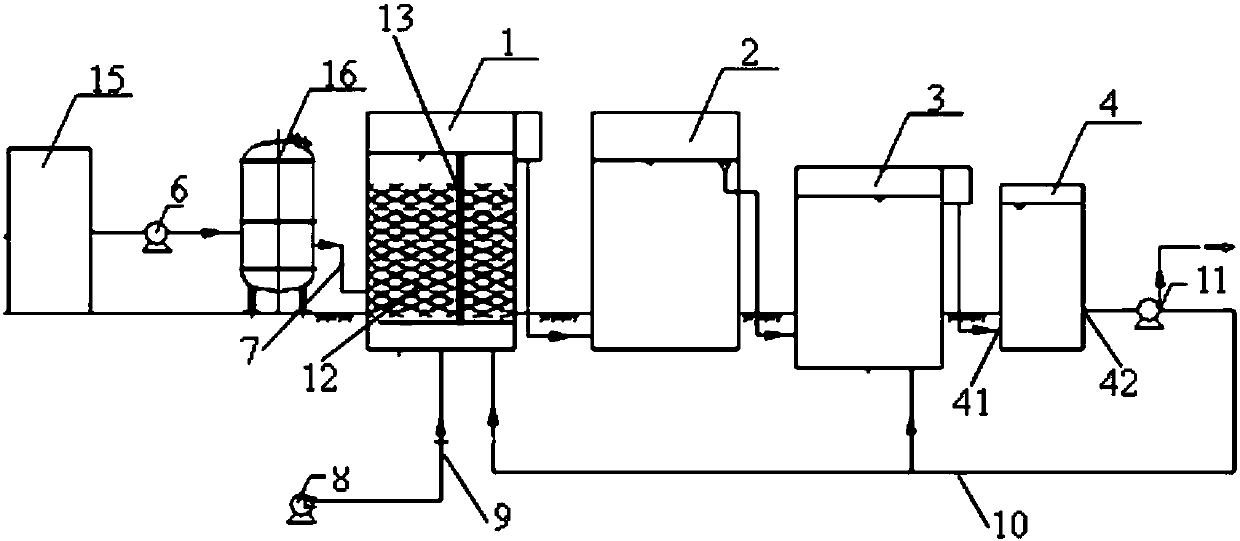

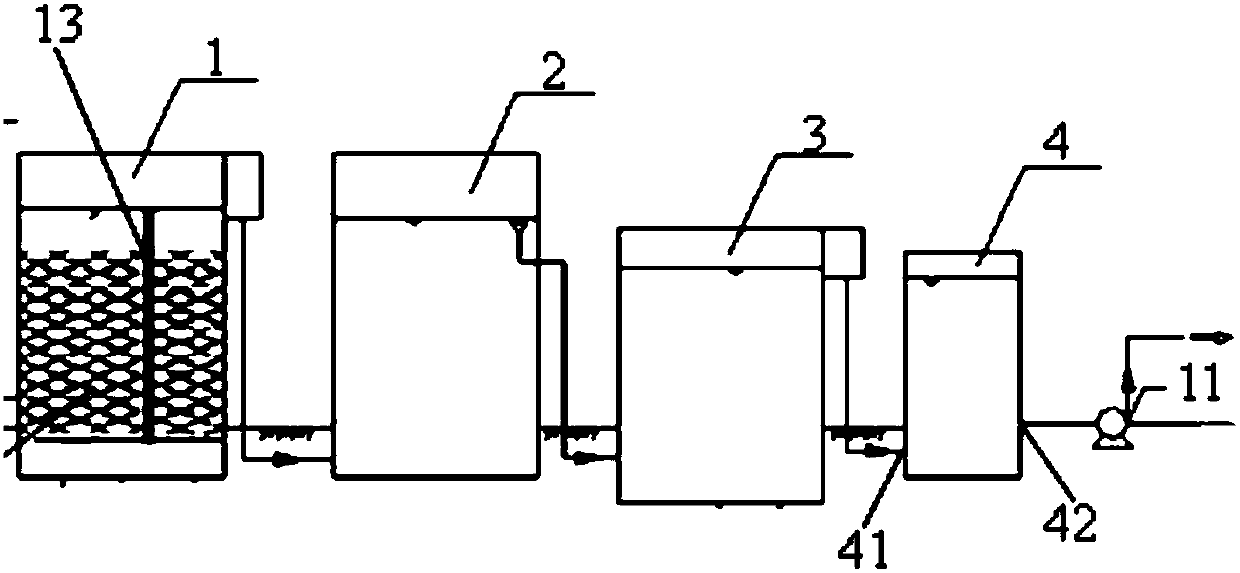

[0038] Embodiments 1 to 4: A petrochemical wastewater discharge treatment equipment, comprising a catalytic oxidation pool 1, an oxidation stabilization pool 2, a post-biochemical BAF pool 3, a clean water pool 4, a water collection pool 15 and a filter 16, the catalytic oxidation pool 1 , oxidation stabilization pool 2, post-biochemical BAF pool 3 and clear water pool 4 are connected by transmission pipeline 5 successively, and described filter 16 is connected to catalytic oxidation pool 1 inside by water inlet pipeline 7, and an ozone generator 8 passes gas pipeline 9 Connected to the inside of the catalytic oxidation tank 1, the clean water tank 4 is provided with a water inlet 41 and a water outlet 42, the water inlet 41 of the clean water tank 4 is connected with the post-biochemical BAF tank 3 through a transmission pipeline 5, and the clean water The outlet hole 42 of the pool 4 is connected to one end of a backwash pump 11, and the other end of the backwash pump 11 is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com