Preparation method of silver-containing copper bar for large-capacity phase regulator

A condenser and large-capacity technology, which is applied in the direction of metal/alloy conductors, can solve problems such as unstable vibration, tripping of the condenser, and large deviations in conductivity, and achieve narrow resistivity deviation ranges, reduce noise and vibration, The effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

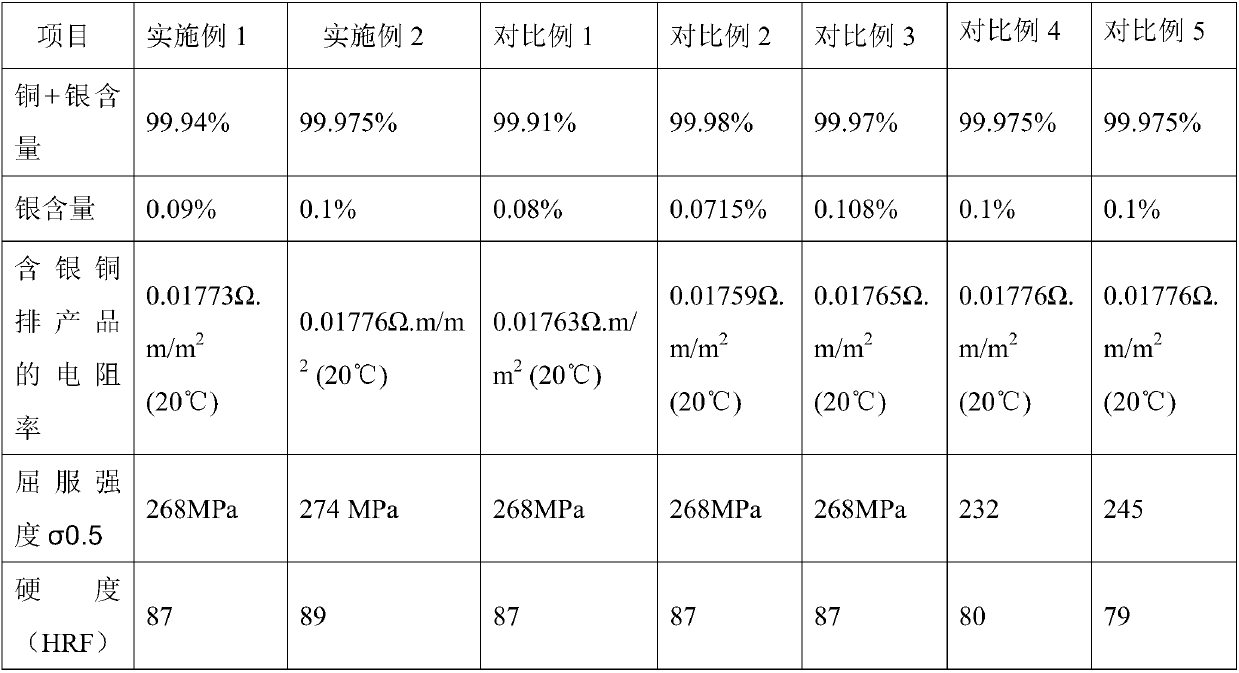

Examples

Embodiment 1

[0027] like figure 1 As shown, the preparation method of silver-containing copper bars for large-capacity condensers is as follows:

[0028] Step 1, material preparation: take silver, iron and electrolytic copper plate respectively; Copper, silver, and iron all contain impurities, so the sum of the gravity percentages of the material components will not be as high as 100%, and the rest are impurities.

[0029] Step 2: Upward continuous casting, using SL-13-10 / φ12.5~φ20 type upward continuous casting unit for production. The process parameters are as follows: lead rod specification φ20mm, cooling water inlet pressure 0.26MPa, cooling water inlet temperature 22°C, temperature difference between inlet and outlet water 7°C, lead rod pitch 5mm, lead rod speed 500mm / min, lead rod temperature 1160°C . Continuously add high-purity electrolytic copper plate, silver and iron during the lead-in process to keep the alloy composition and liquid level unchanged.

[0030] Test the silver...

Embodiment 2

[0034] The difference between this embodiment and embodiment 1 is:

[0035] The preparation method of the silver-containing copper bar for large-capacity condensers is as follows:

[0036] Step 1, material preparation: take silver, iron and electrolytic copper plate respectively; Copper, silver, and iron all contain impurities, so the sum of the gravity percentages of the material components will not be as high as 100%, and the rest are impurities.

[0037] Step 2: Upward continuous casting, using SL-13-10 / φ12.5~φ20 type upward continuous casting unit for production. The process parameters are as follows: lead rod specification φ20mm, cooling water inlet pressure 0.30MPa, cooling water inlet temperature 30°C, temperature difference between inlet and outlet water 9°C, lead rod pitch 7mm, lead rod speed 700mm / min, lead rod temperature 1160°C . Continuously add high-purity electrolytic copper plate, silver and iron during the lead-in process to keep the alloy composition and l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com