Organic/inorganic composite heat insulation coating and preparation method thereof

An inorganic composite and heat-insulating coating technology, applied in the field of chemical coatings, can solve problems such as insufficient adhesion, poor alkali resistance and stain resistance, and easy generation of harmful gases, so as to enhance adhesion, prevent coatings from mildewing, The effect of excellent abnormal temperature luminescence performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

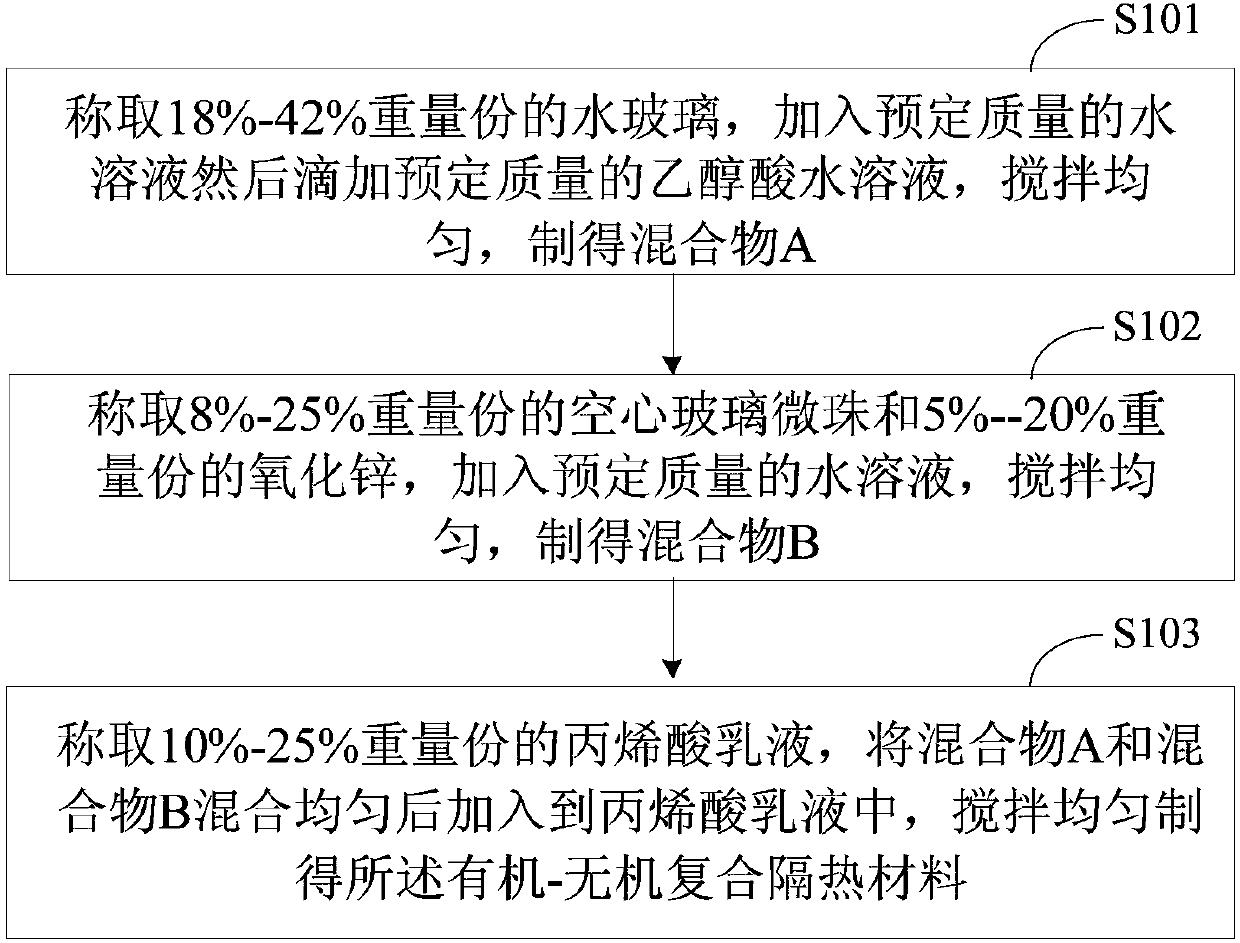

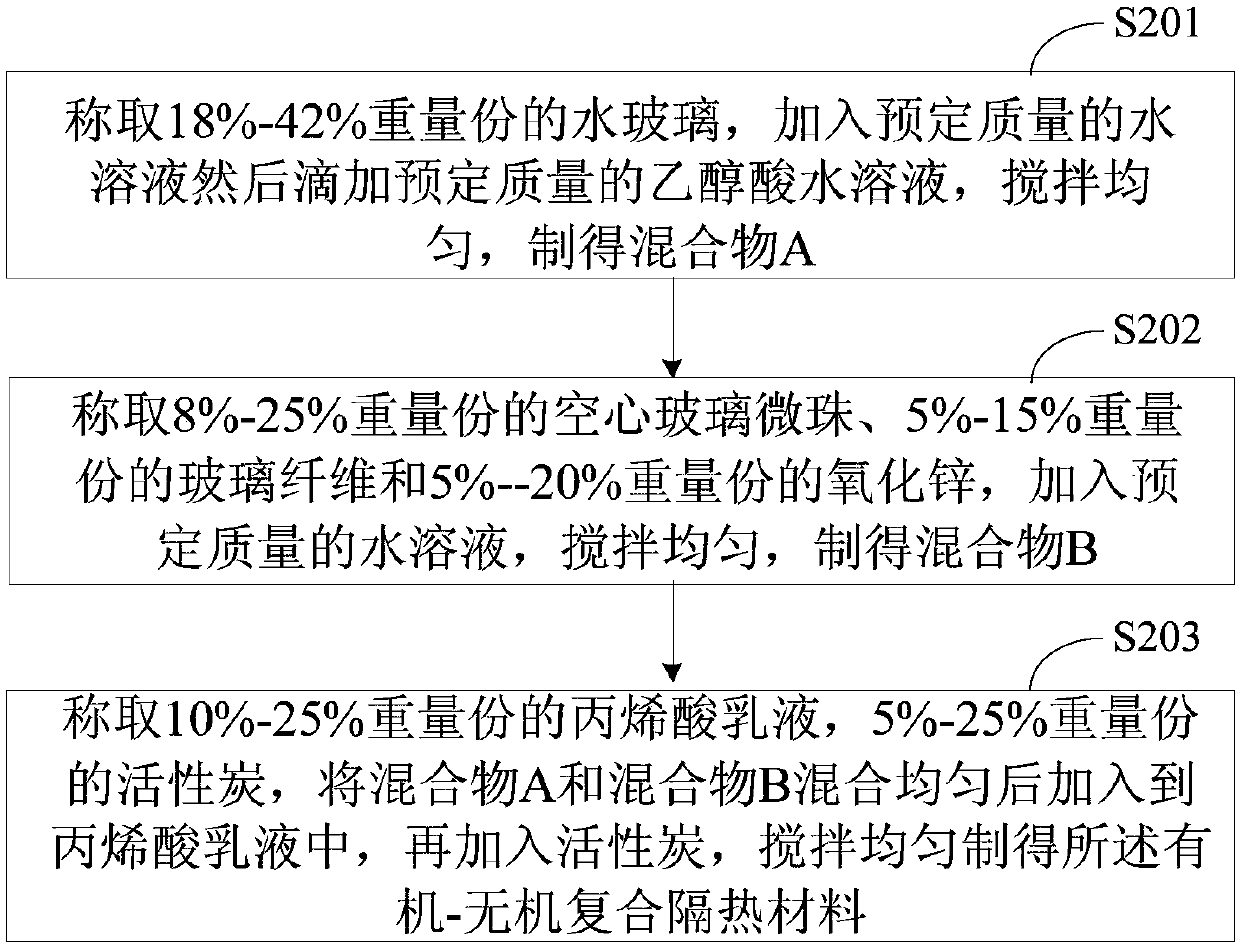

[0055] see figure 1 , figure 1It is a schematic diagram of an embodiment of the preparation method of the organic-inorganic composite thermal insulation coating of the present invention. The present invention also provides a method for preparing an organic-inorganic composite heat-insulating coating. The method of this embodiment is the preparation method of the above-mentioned organic-inorganic composite heat-insulating coating. For details about the relevant content, please refer to the above-mentioned organic-inorganic composite heat-insulating coating part and will not be repeated here. The method comprises the steps of:

[0056] S101: Weighing 18%-42% by weight of water glass, adding a predetermined mass of water to dissolve, then adding a predetermined mass of glycolic acid aqueous solution dropwise, stirring and mixing to prepare a mixture A;

[0057] S102: Weigh 8%-25% by weight of hollow glass microspheres and 5%-20% by weight of zinc oxide, add a predetermined mas...

Embodiment 1

[0077] Weigh 20g of water glass, add 30ml of water to dissolve, then add dropwise 4g of glycolic acid aqueous solution with a mass concentration of 25%, stir and mix, and prepare mixture A for later use;

[0078] Weigh 10g of hollow glass microspheres and 5g of zinc oxide in another flask, add 30ml of water, stir at room temperature for 1 hour, and prepare mixture B for later use;

[0079] Weigh 13g of acrylic emulsion into another flask, mix mixture A and mixture B evenly, add to the acrylic emulsion, stir at room temperature for 1 hour, and prepare coating sample 1.

Embodiment 2

[0081] Weigh 35g of water glass, add 40ml of water to dissolve, then dropwise add 7g of glycolic acid aqueous solution with a mass concentration of 25%, stir and mix, and prepare mixture A for subsequent use;

[0082] Weigh 13g of hollow glass microspheres and 14g of zinc oxide in another flask, add 50ml of water, and stir at room temperature for 2.5 hours to prepare mixture B for later use;

[0083] Weigh 8g of acrylic emulsion into another flask, mix mixture A and mixture B evenly, add to the acrylic emulsion, stir at room temperature for 2 hours, and prepare coating sample 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com