A kind of preparation method of perovskite micro ring array

A technology of perovskite and perovskite precursors, applied in lead halide and other directions, can solve the problems of high cost, high difficulty in operation process, complicated equipment, etc., and achieve the effect of fast reaction speed, low difficulty in operation process and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

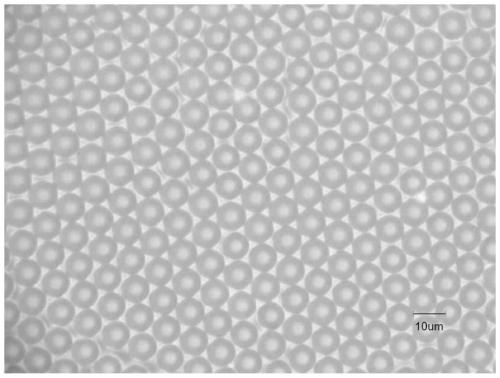

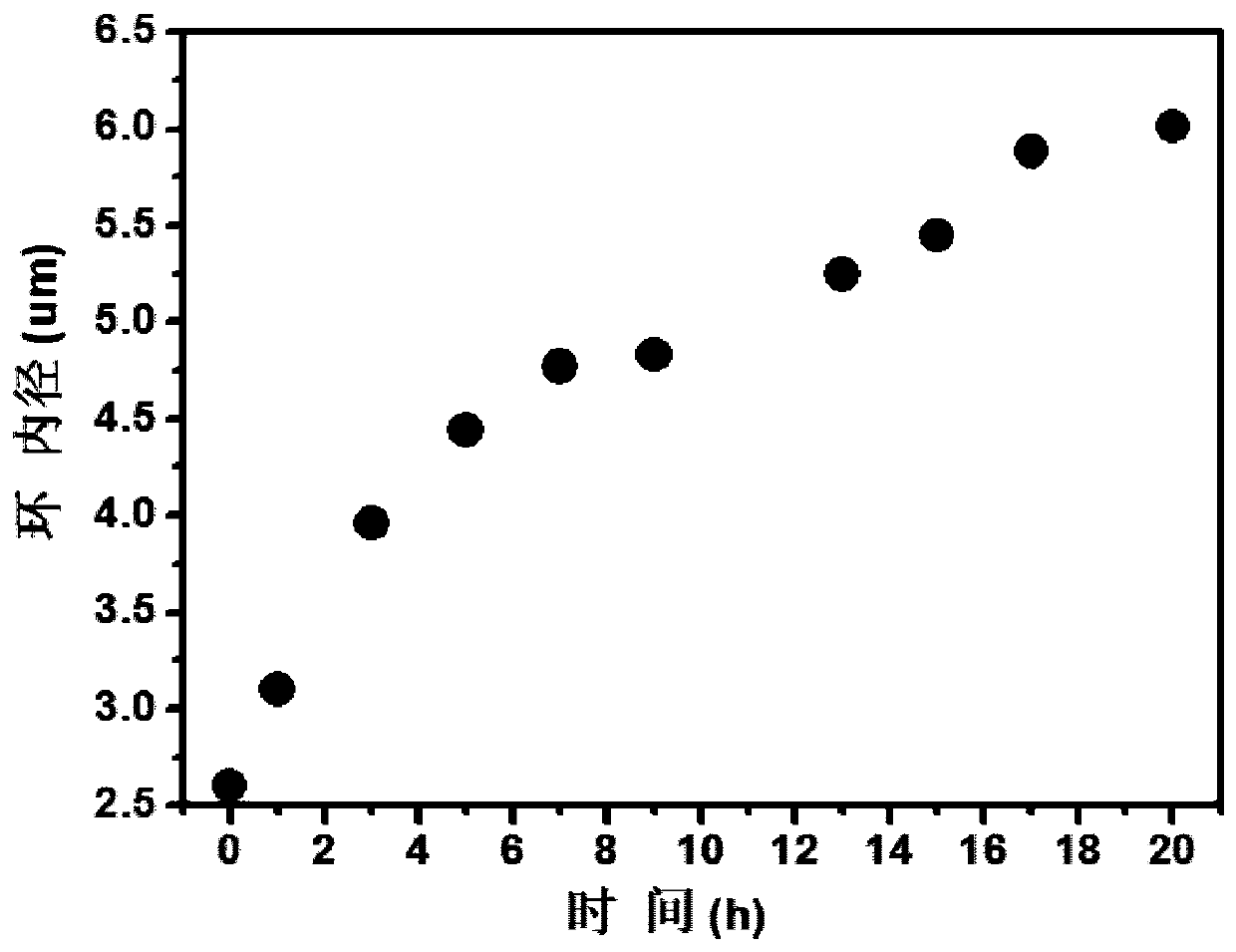

[0028] All-inorganic CsPbBr with an inner diameter of 2.5um 3 Fabrication of perovskite micro-ring arrays

[0029] 1) The glass substrate was sequentially filled with H at a volume ratio of 3:1 2 SO 4 / H 2 o 2 The mixed solution, acetone, isopropanol, ethanol and deionized water were ultrasonically cleaned; then dried with nitrogen and placed in an oven for later use, the suspension of polystyrene microspheres was dropped on the cleaned glass substrate, at 80rpm Spin-coat at a speed of 100°C, and after the water evaporates, a colloidal monolayer template is obtained, wherein the particle size of the polystyrene microspheres is 8um, and the solid content of the emulsion of the polystyrene particles in the polystyrene microsphere suspension is 5.0wt%;

[0030] 2) Mix 1mmolCsBr and 1mmolPbBr 2 Dissolve in 10mL dimethyl sulfoxide to obtain a precursor solution of perovskite;

[0031] 3) Spin-coat the perovskite precursor solution on the colloidal single-layer template at a s...

Embodiment 2

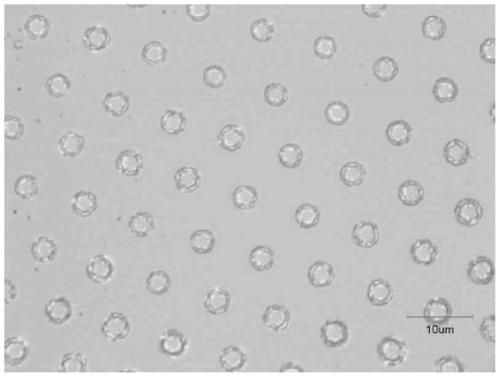

[0035] All-inorganic CsPbBr with an inner diameter of 6um 3 A method for preparing a perovskite micro-ring array, comprising the steps of:

[0036] 1) The glass substrate is sequentially filled with H at a volume ratio of 7:32 SO 4 / H 2 o 2 The mixed solution, acetone, isopropanol, ethanol and deionized water were ultrasonically cleaned; then dried with nitrogen and placed in an oven for later use. Drop the suspension of polystyrene microspheres on the cleaned glass substrate and spin-coat at a speed of 60 rpm. After the water evaporates, place it on a heating platform and heat it at 100°C for 20h or 110°C for 1h, then cool it down to room temperature naturally to obtain A colloidal monolayer template, wherein the particle size of the polystyrene microspheres is 10um, and the solid content of the polystyrene microparticle emulsion in the polystyrene microsphere suspension is 2.5wt%;

[0037] 2) Mix 0.8mmolCsBr and 1mmolPbBr 2 Dissolve in 10mL dimethyl sulfoxide to obtain ...

Embodiment 3

[0041] All-inorganic CsPb(Cl) with an inner diameter of 2.5um 0.3 Br 0.7 ) 3 Fabrication of perovskite micro-ring arrays

[0042] 1) The glass substrate was sequentially filled with H at a volume ratio of 8:3 2 SO 4 / H 2 o 2 The mixed solution, acetone, isopropanol, ethanol and deionized water were ultrasonically cleaned; then dried with nitrogen and placed in an oven for later use. Drop the suspension of polystyrene microspheres on the cleaned glass substrate and spin-coat at a speed of 80 rpm. After the water evaporates, place it on a heating table and heat it at 110°C for 1 hour, then cool it down to room temperature naturally to obtain a colloidal single-layer template; Wherein the particle size of the polystyrene microsphere is 9um, and the solid content of the emulsion of the polystyrene microsphere in the polystyrene microsphere suspension is 3.5wt%;

[0043] 2) 1mmolCsBr, 0.7mmolPbBr 2 and 0.3mmolPbCl 2 Dissolve in 10mL dimethyl sulfoxide after mixing to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com