Cellulose-based sustained release type fat-soluble vitamin tablet and preparation method thereof

A fat-soluble vitamin, based slow-release technology, applied in the field of cellulose-based slow-release fat-soluble vitamin tablets and its preparation, can solve the problems of fat-soluble vitamins such as poor solubility, low bioavailability, and frequent taking, and achieve biological Degradation is easy to modify, good biocompatibility, and fast biodegradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

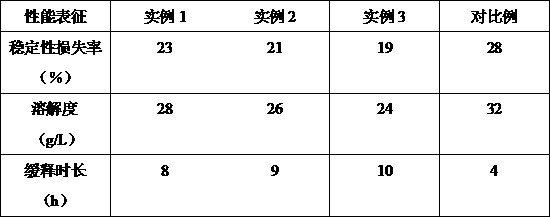

Examples

example 1

[0019] Take 100g of cellulose, add 400mL of 10% sodium hydroxide solution, stir at 30°C for 20min at 300r / min, then add 10g of hexadecane bromide, keep it warm for 3h, cool to room temperature and filter to obtain the filter residue , wash the filter residue with deionized water until the washing liquid is neutral, then transfer it to a drying oven, and dry it to constant weight at 105°C to obtain hexadecyloxycellulose. Take 50g of hexadecyloxycellulose, 20g Ethyl cellulose and 10g of lactose were put into a grinder and ground, passed through a 100-mesh sieve to obtain a composite powder. Take 1g of the composite powder, add 4g of the compound powder to a 50% ethanol solution, stir at 200r / min for 30min, and then Add 100mg of fat-soluble vitamins, mix evenly, place in a drying oven, dry at 50°C for 1 hour, then put into a kneader to granulate, pass through a 24-mesh sieve for granulation, and then mix with 0.1g magnesium stearate evenly Put it in a tablet machine, and press it...

example 2

[0021] Take 150g of cellulose, add it to 600mL of 10% sodium hydroxide solution, stir at 32°C at 350r / min for 25min, then add 15g of hexadecane bromide, keep it warm for 4h, cool to room temperature and filter to obtain the filter residue , wash the filter residue with deionized water until the washing liquid is neutral, then transfer it to a drying oven, and dry it to a constant weight at 107°C to obtain hexadecyloxycellulose. Take 55g of hexadecyloxycellulose, 25g Ethyl cellulose and 20g lactose were put into a grinder and ground, and passed through a 100-mesh sieve to obtain a composite powder. Take 1g of the composite powder, add 6g of the composite powder to a 63% ethanol solution, stir at 250r / min for 35min, and then Add 150mg of fat-soluble vitamins, mix evenly, place in a drying oven, dry at 55°C for 2 hours, then put into a kneader to granulate, pass through a 24-mesh sieve for granulation, and then mix with 0.15g magnesium stearate evenly Put it in a tablet machine, ...

example 3

[0023] Take 200g of cellulose, add 800mL of 10% sodium hydroxide solution, stir at 35°C at 400r / min for 30min, then add 20g of hexadecane bromide, keep it warm for 5h, cool to room temperature and filter to obtain the filter residue , wash the filter residue with deionized water until the washing liquid is neutral, then transfer it to a drying oven, and dry it to constant weight at 110°C to obtain hexadecyloxycellulose. Take 60g of hexadecyloxycellulose, 30g Ethyl cellulose, 30g lactose, grind in grinder, cross 100 mesh sieves, get composite powder, get 2g composite powder, add 8g mass fraction and be in 75% ethanol solution, stir 40min with 300r / min, then Add 200mg of fat-soluble vitamins, mix evenly, place in a drying oven, dry at 60°C for 3 hours, then put into a kneader to granulate, pass through a 24-mesh sieve for granulation, and then mix with 0.2g magnesium stearate evenly Put it in a tablet machine, and press it into tablets to obtain cellulose-based slow-release fat-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com