Preparation method of nickel-cobalt-manganese ternary positive material precursor of lithium-ion battery

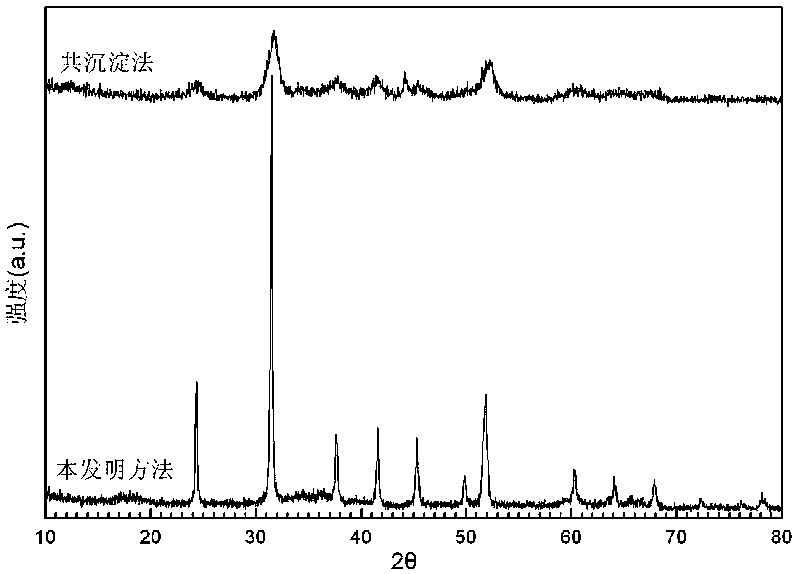

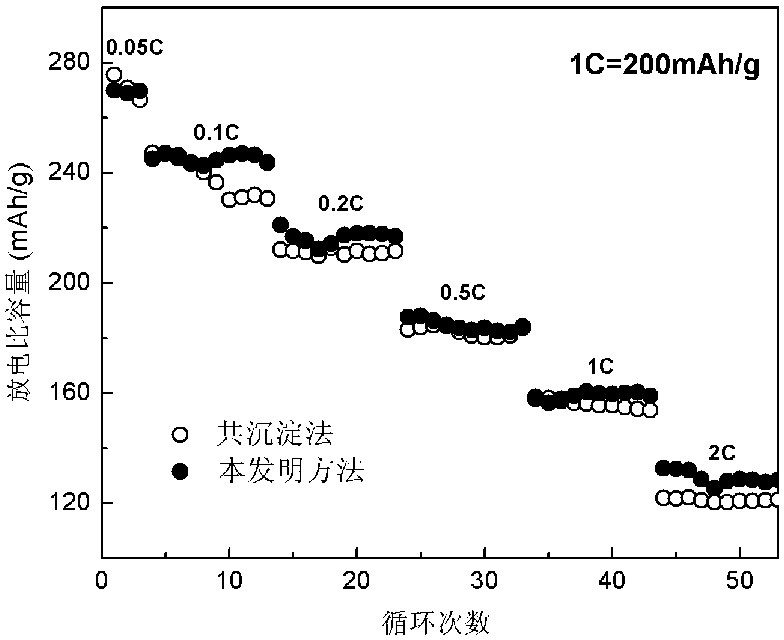

A technology for lithium-ion batteries and cathode materials, applied in battery electrodes, electrical components, secondary batteries, etc., can solve problems such as low crystallinity and incomplete co-precipitation, and achieve excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

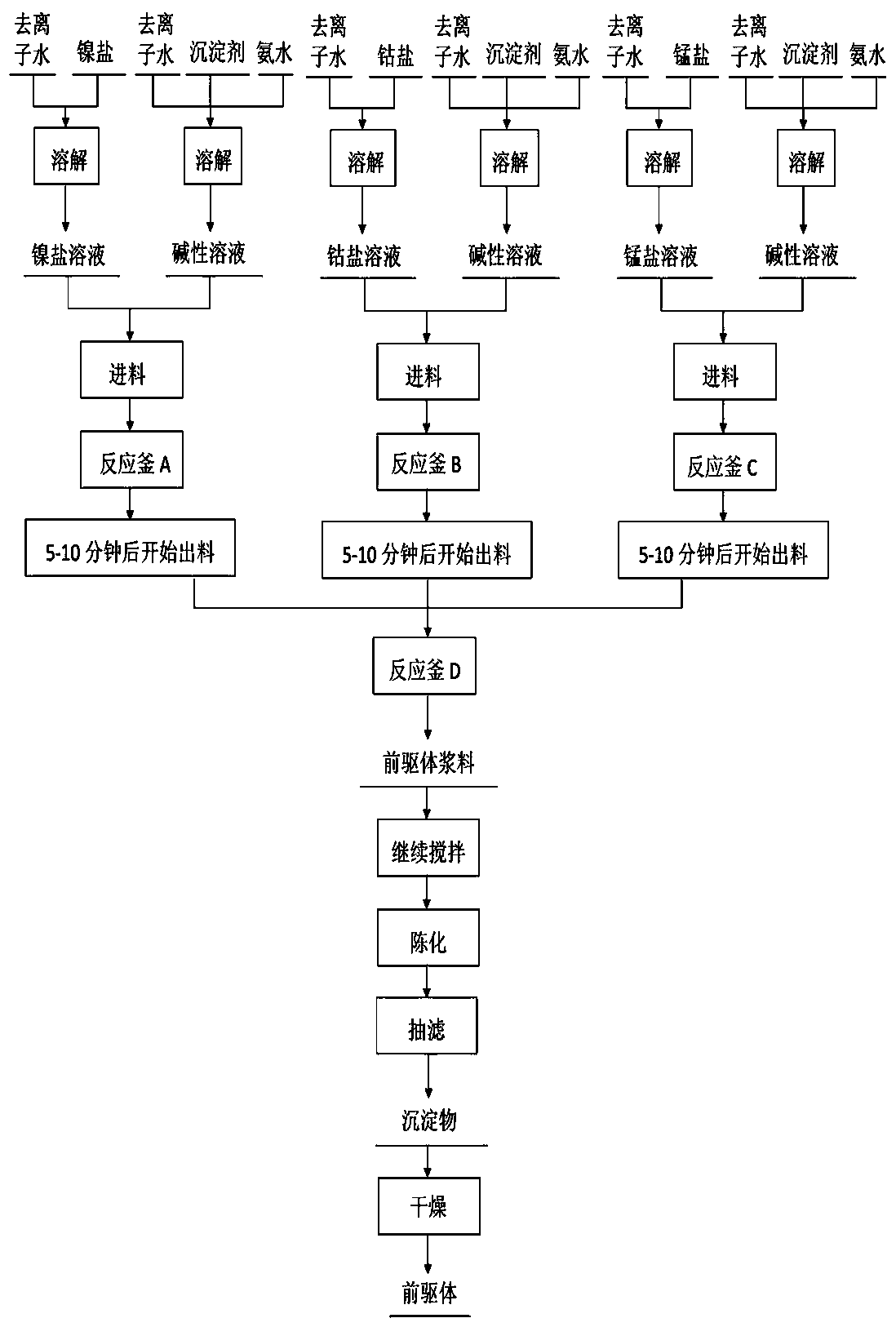

Method used

Image

Examples

Embodiment 1

[0026] What this example prepares is positive electrode material Li 1.2 Ni 0.133 co 0.133 mn 0.533 o 2 precursors.

[0027] In this example, the material ratio of Ni:Co:Mn is x:y:z=1:1:4.

[0028] Weigh 0.04mol Ni(CH 3 COO) 2 4H 2 O was dissolved in deionized water to prepare a 100mL solution, and stirred for 20min to obtain a nickel ion concentration of 0.4mol L -1 Nickel salt solution; Weigh 0.04mol Co(CH 3 COO) 2 4H 2 O was dissolved in deionized water to prepare a 100mL solution, and stirred for 20min to obtain a cobalt ion concentration of 0.4mol L -1 cobalt salt solution; weigh 0.16mol Mn(CH 3 COO) 2 4H 2O was dissolved in deionized water to prepare a 400mL solution, and stirred for 20min to obtain a manganese ion concentration of 0.4mol L -1 Manganese salt solution; Weigh 0.45mol Na 2 CO 3 and 19.2g ammonia water (including NH 3 25%~28%) mixed and dissolved in deionized water to prepare a 500mL solution, stirred for 20min to obtain an alkaline solutio...

Embodiment 2

[0044] What is prepared in this example is the positive electrode material LiNi 0.5 co 0.2 mn 0.3 o 2 precursors.

[0045] In this example, the material ratio of Ni:Co:Mn is x:y:z=5:2:3.

[0046] Weigh 0.1mol NiSO 4 ·6H 2 O was dissolved in deionized water to prepare a 100mL solution, and stirred for 20min to obtain a nickel ion concentration of 1mol L -1 Nickel salt solution; Weigh 0.04mol CoSO 4 ·7H 2 O was dissolved in deionized water to prepare a 40mL solution, and stirred for 20min to obtain a cobalt ion concentration of 1mol L -1 cobalt salt solution; weigh 0.06mol MnSO 4 ·H 2 O was dissolved in deionized water to prepare a 60mL solution, and stirred for 20min to obtain a manganese ion concentration of 1mol L -1 manganese salt solution; Weigh 0.6mol NaOH and 15mL ammonia water (containing NH 3 25%~28%) mixed and dissolved in deionized water to prepare a 200mL solution, stirred for 20min to obtain an alkaline solution, in which NaOH and NH 3 The molar ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com