A Common Ditch Seismic Isolation System

A Seismic Isolation System, Common Ditch Technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The above and other technical features and advantages of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them.

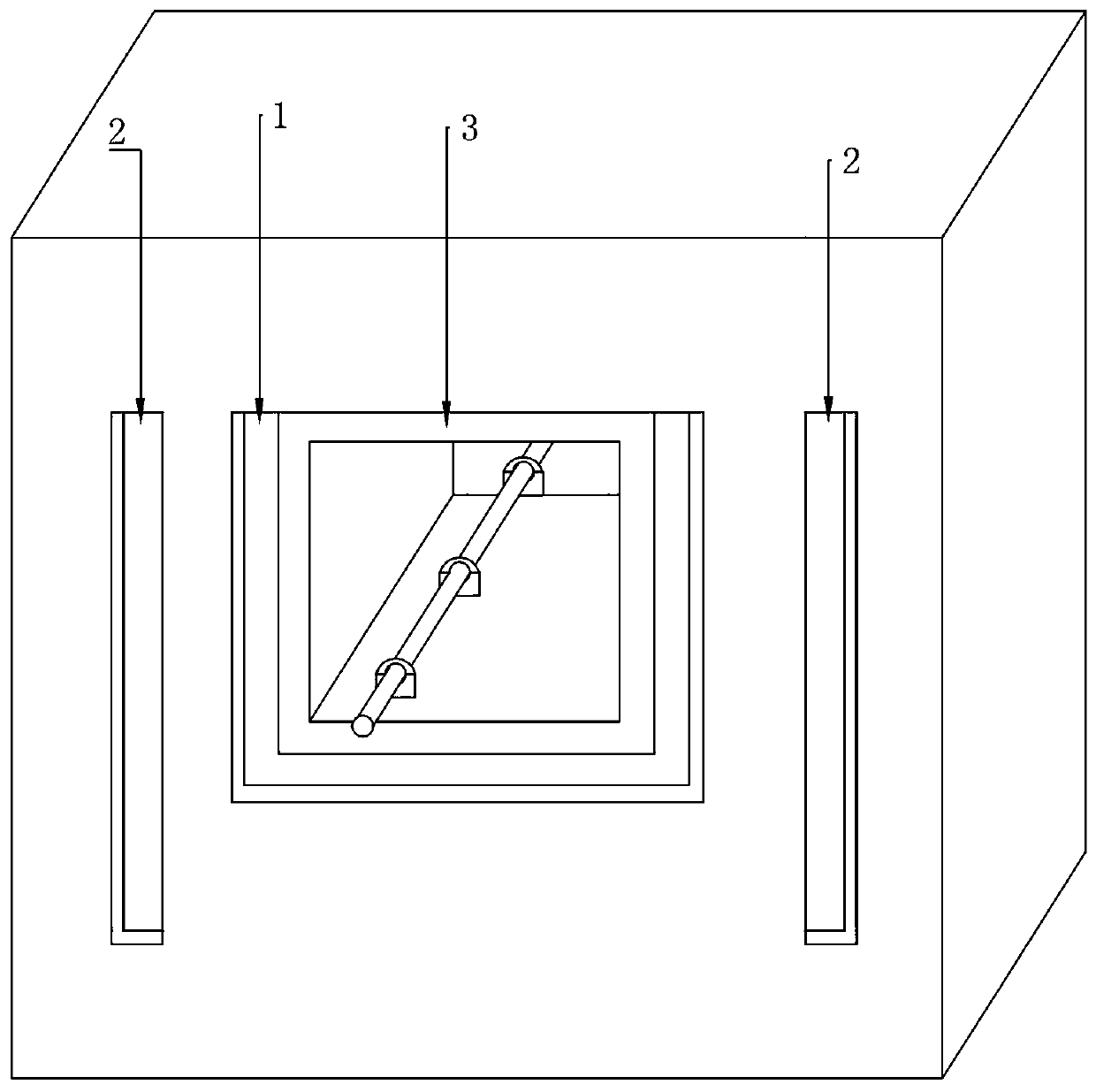

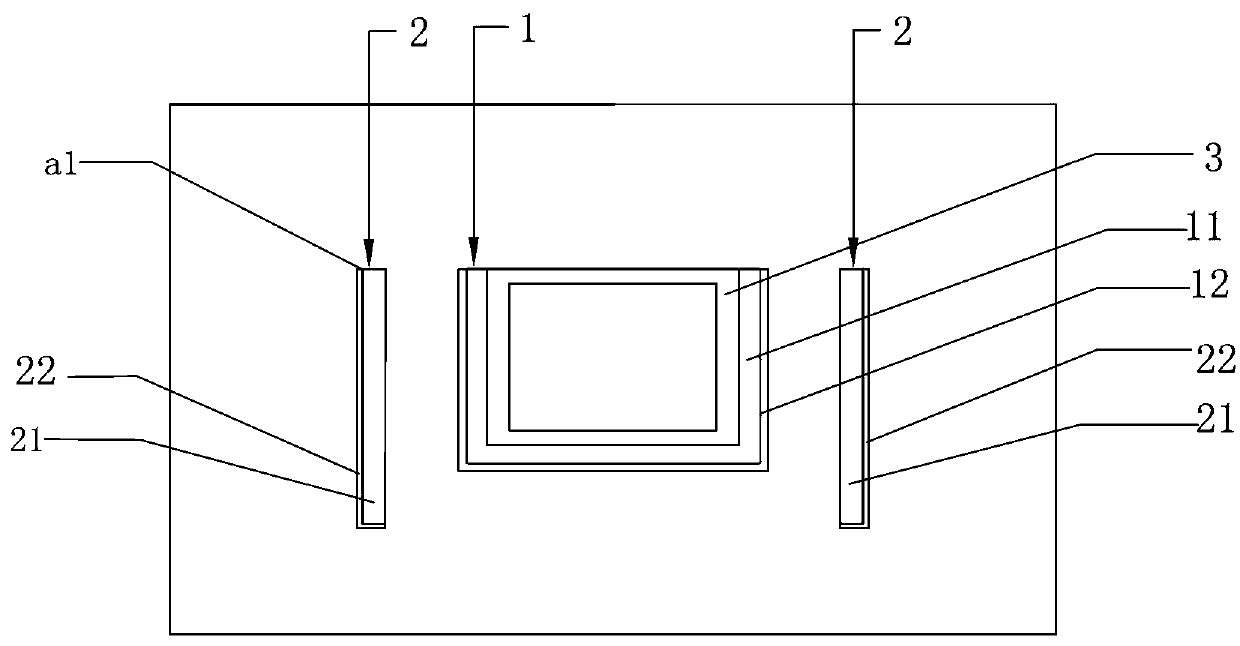

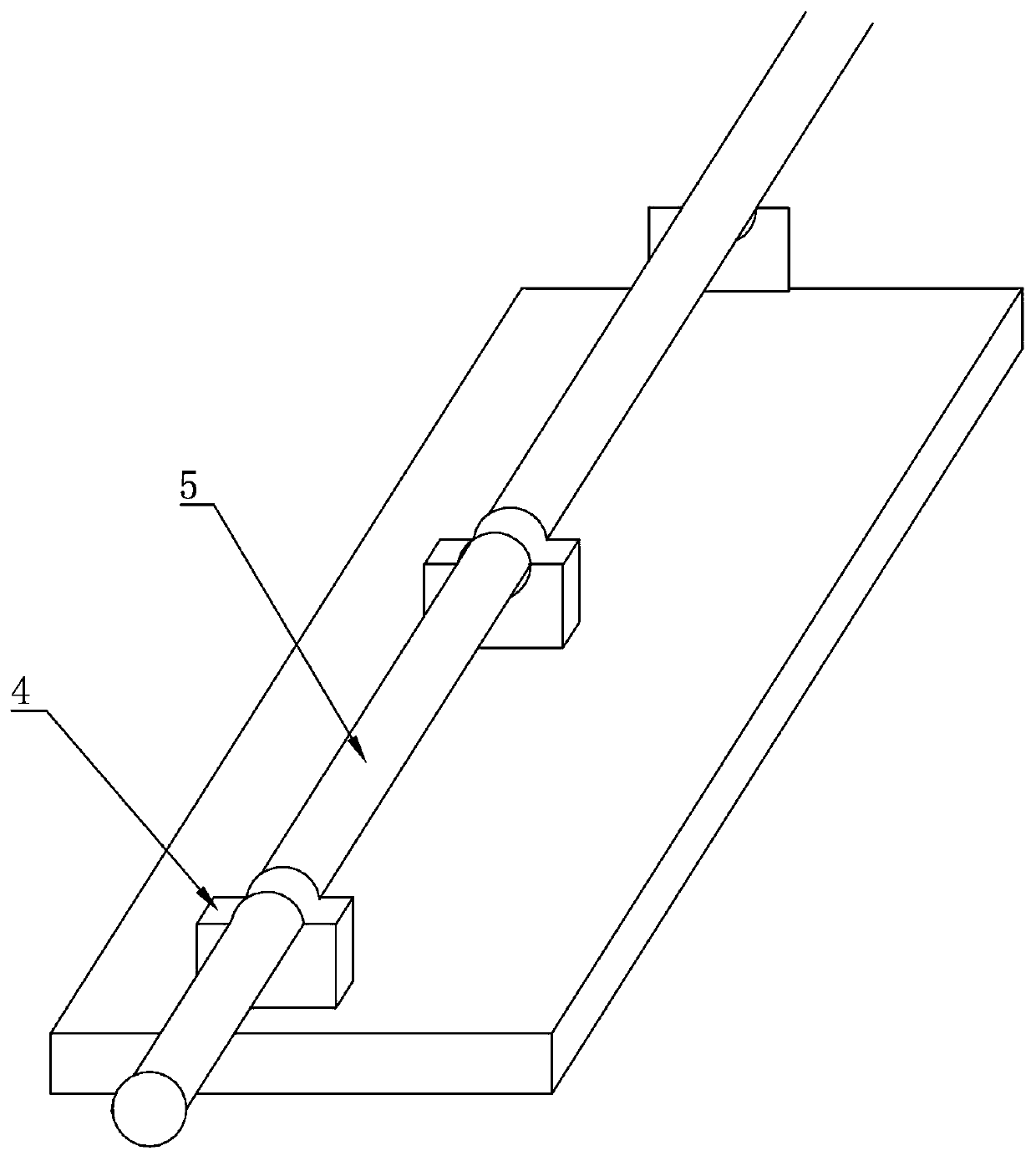

[0030] refer to figure 1 , this embodiment provides a three-dimensional structure arrangement of a common trench isolation system. The common ditch is generally constructed underground by the method of open cut and shallow burial. The cross section of the common ditch concrete layer 3 is generally square, and a few of them are circular or semicircular. , water conservancy, gas and other pipelines or lines. Common ditch concrete layer 3 generally adopts reinforced concrete cast-in-place structure, surrounded by underground soil. In order to counteract the impact of seismic waves, in this embodiment, an outer shock-isolation layer 1 and two-side shock-isolation layers 2 are respectively...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com