WC-Co-cBN composite hard alloy and preparation method thereof

A cemented carbide, wc-co-cbn technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of poor thermal stability of cBN, low density of cemented carbide, cBN particles falling off, etc., to achieve wear resistance. Good, strong metallurgical force, fine grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

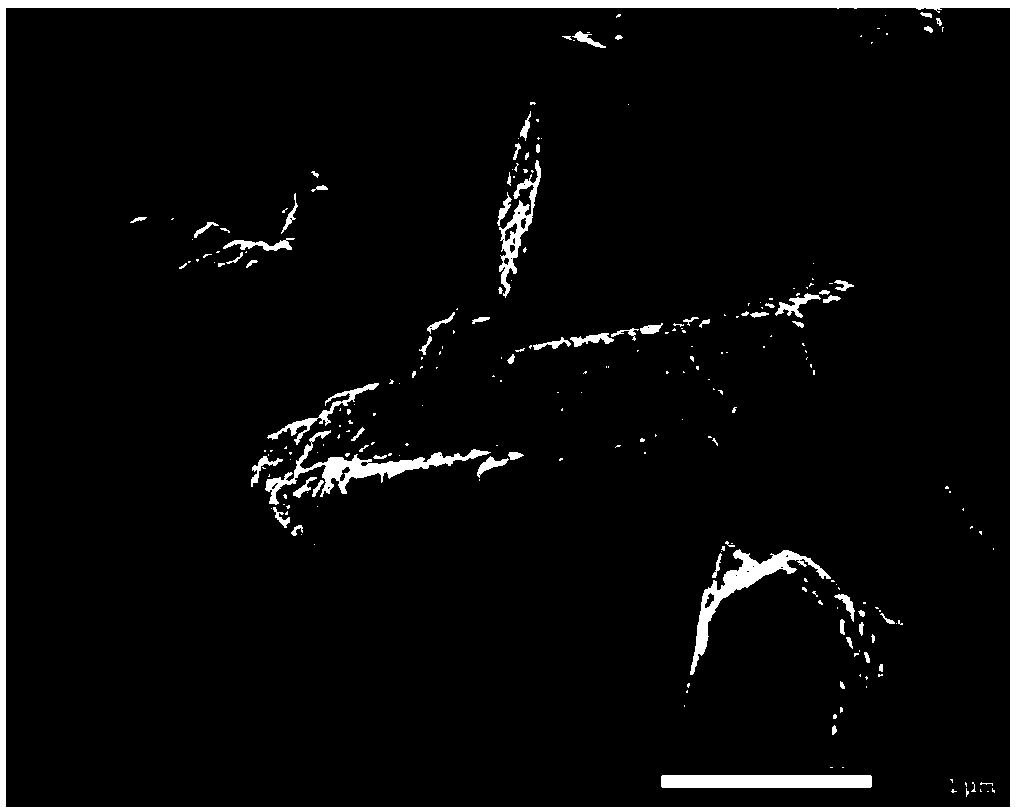

[0030] 1) Weighing: 82.9% WC powder (Fischer particle size is 0.4 μm) by mass fraction, 12% Co powder (Fischer particle size is 0.8 μm), 0.35% VC powder, 0.25% Cr 3 C 2 Powder, 4% cBN powder coated with Mo on the surface (original Fibonacci particle size 2μm, such as figure 1 shown), 0.5% of 6AlY24Cr70Ni spherical powder (such as figure 2 shown).

[0031] 2) Mixing and ball milling: Weigh raw materials WC powder, Co powder, VC powder, Cr powder in proportion 3 C 2 Add the powder into the rolling ball mill tank, the ball milling medium is anhydrous alcohol, the ball is YG8 ball (Φ6), the ball-to-material ratio is 4:1, the ball milling speed is 60r / min, and the ball milling time is 36h; then add cBN coated with Mo in proportion powder, continue ball milling for 3h under the same ball milling parameters; finally add 6AlY24Cr70Ni powder, and ball mill for 1h.

[0032] 3) Vacuum drying: the drying temperature is 85° C., the vacuum degree is -0.1 Pa, and the drying time is 7 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com