Plugging cement composition for drilling fractured leakage as well as cement slurry and preparation method thereof

A technology of composition and cement slurry, which is applied in the direction of drilling composition, chemical instruments and methods, educts, etc., can solve the problems of cracked leakage, malignant leakage, plugging success rate, etc., and achieve simple and adjustable formula, plugging Quick and wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

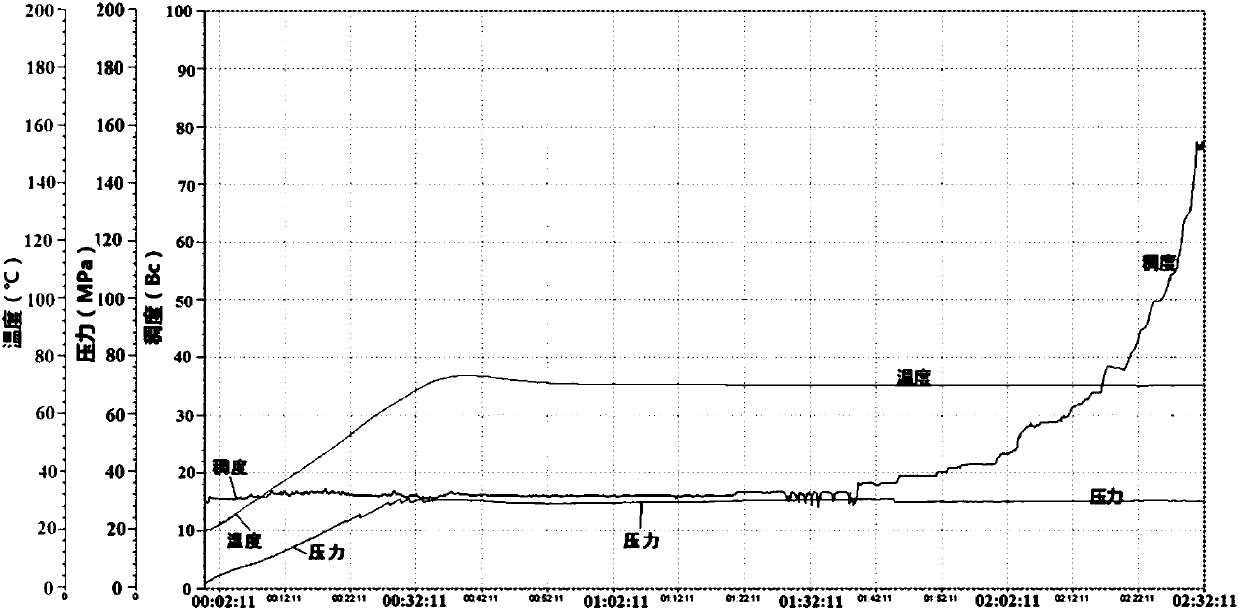

Image

Examples

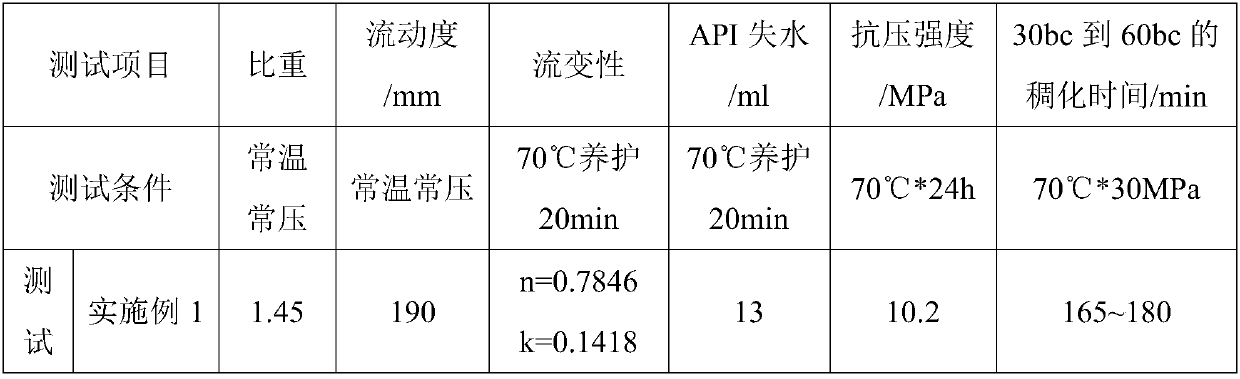

Embodiment 1

[0034] The plugging cement composition for drilling fracture loss in this embodiment consists of the following components by weight: 100 parts of oil well cement, 9.5 parts of lightening agent, 9.5 parts of micro silicon, 1.2 parts of expansion agent, and fluid loss reducer 2 parts, 0.28 parts of retarder, 0.06 parts of tackifier, 1.2 parts of short fiber, 2.4 parts of long fiber; lightening agent is artificial floating beads, short fiber is glass fiber with a length of 5mm, and long fiber is glass fiber with a length of 19mm For fiber, the retarder is calcium lignosulfonate, the tackifier is polyacrylamide potassium salt, and the fluid loss reducer is polyvinyl alcohol cross-linked by borax.

[0035] The cement slurry in this embodiment is composed of the plugging cement composition for drilling fluid fracture loss and water in this embodiment, and the mass ratio of water and oil well cement in the plugging cement composition for drilling fluid fracture loss is 107 :100.

[...

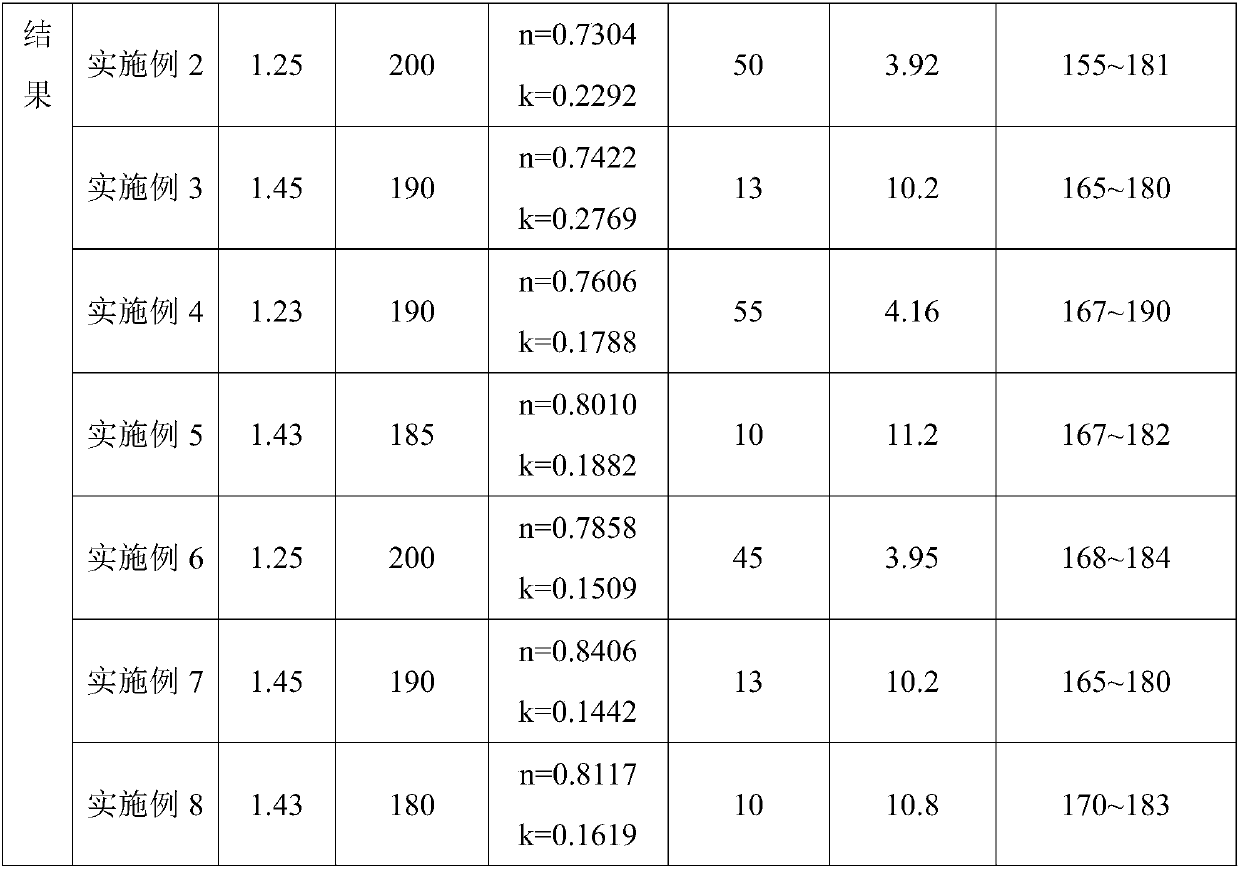

Embodiment 2

[0040] The plugging cement composition for drilling fracture loss in this embodiment is composed of the following components in parts by weight: 100 parts of oil well cement, 36 parts of lightening agent, 7 parts of micro silicon, 1.4 parts of expansion agent, and fluid loss reducer 3.6 parts, 0.15 parts of retarder, 0.05 parts of tackifier, 1.4 parts of short fibers, 2.8 parts of long fibers; lightening agent is artificial floating beads, short fibers are asbestos fibers with a length of 3 mm, and long fibers are asbestos fibers with a length of 6 mm For fiber, the retarder is calcium lignosulfonate, the tackifier is polyacrylamide potassium salt, and the fluid loss reducer is polyvinyl alcohol cross-linked by borax.

[0041] The cement slurry in this embodiment is composed of the plugging cement composition for drilling fluid fracture loss and water in this embodiment, and the mass ratio of water and oil well cement in the plugging cement composition for drilling fluid fractu...

Embodiment 3

[0044]The plugging cement composition for drilling fracture loss in this embodiment consists of the following components by weight: 100 parts of oil well cement, 9.5 parts of lightening agent, 9.5 parts of micro silicon, 1.2 parts of expansion agent, and fluid loss reducer 2.4 parts, 0.28 parts of retarder, 0.06 parts of viscosifier, 3.5 parts of short fiber, 1 part of long fiber; lightening agent is artificial floating beads, short fiber is glass fiber with a length of 3mm, and long fiber is asbestos with a length of 10mm For fiber, the retarder is calcium lignosulfonate, the tackifier is polyacrylamide potassium salt, and the fluid loss reducer is polyvinyl alcohol cross-linked by borax.

[0045] The cement slurry in this embodiment is composed of the plugging cement composition for drilling fluid fracture loss and water in this embodiment, and the mass ratio of water and oil well cement in the plugging cement composition for drilling fluid fracture loss is 107 :100.

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com